How is water purified in a waste water treatment plant?

The process of eliminating unwanted chemicals, biological pollutants, suspended particles, and gases from water is known as water purification.

The objective is to provide water that is suitable for a variety of uses. Although most water is cleaned and disinfected for human consumption (drinking water), it can also be used for a variety of other purposes, such as medicinal, pharmaceutical, chemical, and industrial uses. Water cleansing has been done in a variety of ways throughout history. Physical procedures like filtration, sedimentation, and distillation are utilised; biological processes like slow sand filters or biologically active carbon are used; chemical processes like flocculation and chlorination are used; and electromagnetic radiation like ultraviolet light is used.

Purification of water can decrease the amounts of suspended particles, bacteria, algae, viruses, parasites, and fungi, as well as a variety of dissolved and particulate materials.

What is coagulation?

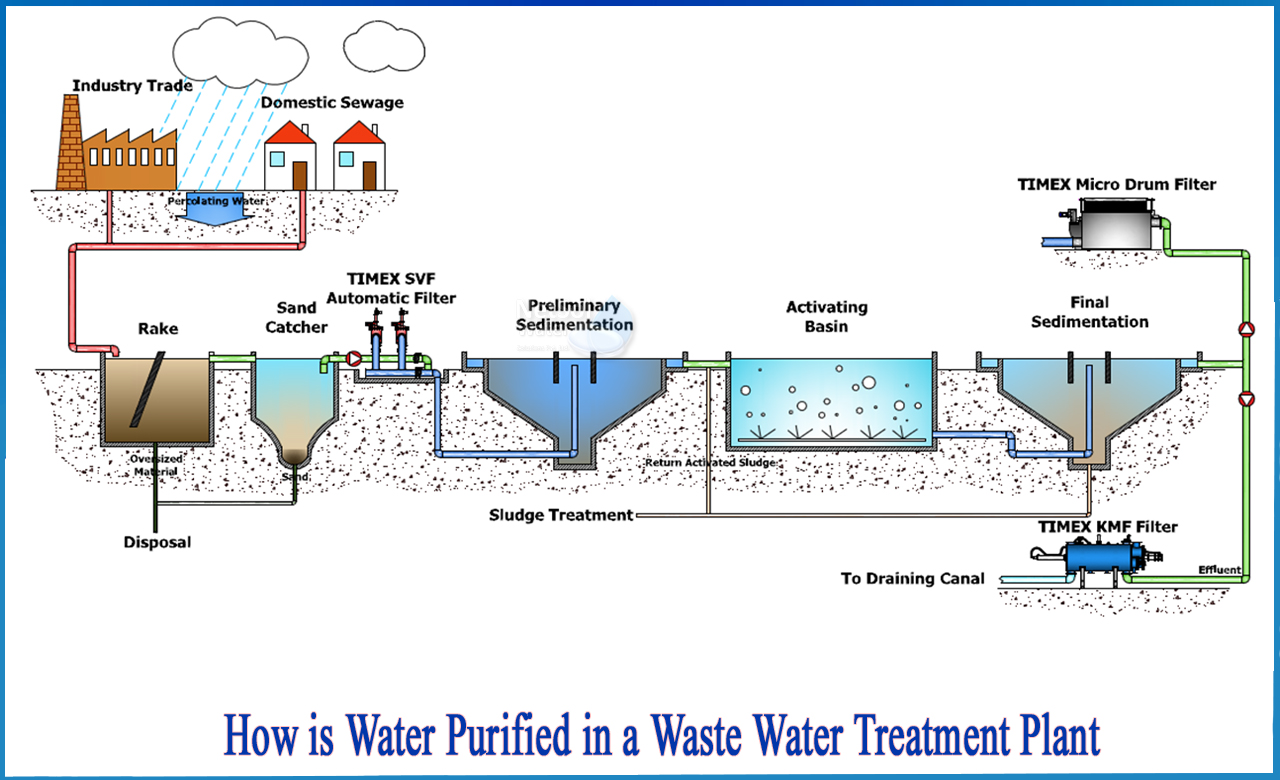

When water enters a treatment facility, the first step is coagulation, which involves adding chemicals to the water to help microparticles and small solids stay together. Chemicals like polyelectrolyte, ferrous sulphate, and aluminium sulphate are used to assist coagulation in water treatment plants.

Since chemical measurements must be accurate, adding these coagulating agents during these water treatment plant processes needs careful administration by expert engineers. Within water treatment plants, quality criteria must also be met as part of the regulatory processes. This includes having qualified engineers maintain the system on a regular basis.

What is flocculation?

After being treated with coagulating agents, the water is pumped into a tank containing massive paddles. These combine the chemicals and water, allowing the micro particles to produce larger pieces that are more likely to cling together, making the water treatment sedimentation process more successful. Flocculation is the term for this process.

What is sedimentation?

The water enters the sedimentation phase when the flocculation process is completed. The big particles generated during the coagulation and flocculation stages separate and settle once the water reaches the major settling basins. This results in cleaner water for treatment at the treatment facility. The sediments settle to the bottom of the tank, forming a sludge layer that is eventually deleted via sludge thickening and reused on the land.

What is disinfection?

During the disinfection water treatment step, chlorine is injected after cleared water leaves the sedimentation basins in the treatment plant. Following the chlorine wastewater treatment, ammonia is produced, resulting in chloramine. To finish the disinfection process, the chloramine-treated water is sent through a second set of basins.

pH Adjustment

After disinfection, the water is subjected to a pH treatment. By altering the pH, lime or calcium oxide make the water less acidic. Domestic water pipes are also less corroded. At this point, a polyphosphate solution is added to the water to maintain the lime mixed.

What is fluoridation?

Fluorosilicic acid is introduced in modest amounts once the water has exited the sedimentation basins. This helps to fluoridate the water supply, which helps to prevent tooth decay.

What is filtration?

Finally, water passes through quick gravity filters for filtration. This sort of filter is generally made of sand, which eliminates any remaining dirt or particles in the water. During the final stage, water is regulated as it passes through a filter. Any particles stuck to the filter are filtered out, leaving only clean water to be delivered into the municipal system. Pumping stations use pipelines to deliver water to domestic users.

Conclusion

The processes at water purification plants are crucial to ensuring a safe supply of water for public and commercial use. The procedures must be quality-checked on a regular basis to guarantee that standards are maintained and that the public receives clean, safe water. This necessitates the use of people with experience in maintaining treatment plants and an understanding of how water is cleansed.

Users will not have to worry about planned maintenance visits or quality inspections since Netsol Water will provide the finest service possible.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.