- For Enquiry- 0120-2350053 || +91 9650608473 || +91 9650795306

- enquiry@netsolwater.com

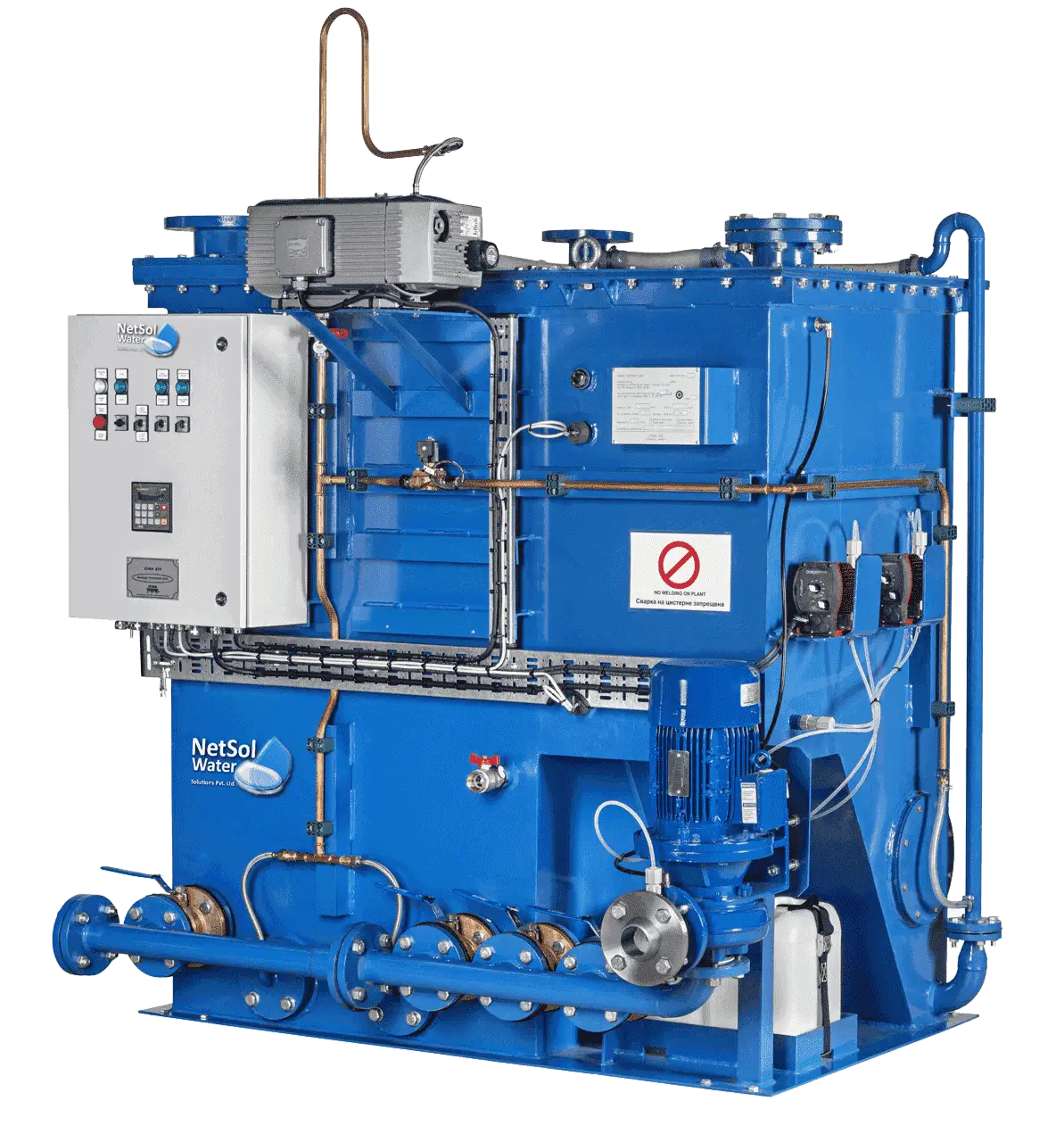

Effluent Treatment Plant is a process design for treating the industrial wastewater for its reuse or safe disposal to the environment.

Industries create large amounts of wastewater through their manufacturing processes. This wastewater threatens our environment when left untreated. ETP Plants manage this challenge by transforming contaminated industrial water into safe water. The treatment process removes harmful pollutants to prepare water for discharge or reuse. Companies benefit from these plants as they help maintain environmental compliance while protecting our natural resources.

• Influent: Untreated industrial wastewater.

• Effluent: It is the Treated industrial wastewater.

• Sludge: It is a Solid part which is separated from waste water by ETP.

ETP Plant cleans industrial effluents, contaminated water from rivers and lakes, then on just so as to reuse the water for extra purposes. Along such lines, water is reutilized and sustained. In fact, such gushing treatment ensures that any contaminant is going to be expelled from the water making it reusable. it's mostly utilized in industries like pharmaceuticals, textiles, tanneries, and chemicals where there's an opportunity of utmost water contamination. Nevertheless, how this treatment is going to be applied may vary from industry to industry.

Effluent treatment plant ensures that the contaminated and polluted water from the industries get managed and become reusable of its every drop, before being released back to nature. Without this treatment, it won’t be possible for humans to urge clean usable water for household chores.

ETP plays a crucial role in treating industrial wastewater also as sewages generated from households. Packaged etp plants help both small- and medium-sized industries by removing the effluents generated at their facilities. Otherwise, it might be difficult for them to properly treat wastewater. they could also get to have extra space for contaminated water treatment. However, they'll get to treat the water for the aim of solid evacuation to make sure that the sewer can flow freely. Also, the expulsion of some toxins is important before release the wastewater in the mother nature.

• leads to clean reusable water - ETPs manufactured by Netsol Water ensure safe and clean water. Before the inception of this amazing treatment plant, people were hardly aware that polluted and impure water are often reused. ETPs treated the water by eliminating toxins from the water so as to get safe and clean water.

• Saves you money — It also ensures complying with industry standards and regulations.

• Saves our planet — ETPs remove any unsafe chemical from water so as to treat it and make it ready for reuse. So when this treated water will enter the bottom, it'll leave no negative effect on the earth.

• Saves water — ETPs are the simplest thanks to serving Mother Nature in a better way.

ETP plants helps to purify wastewater generated from households also as an industry. The treatment process leads to reusable clean water saves your money also like water and our planet.

Industrial expansion has increased wastewater generation dramatically. This water pollutes rivers, lakes and other water bodies when industries release it without treatment. ETP plants address this challenge by enabling industries to process wastewater in environmentally responsible ways. The plants ensure companies follow legal requirements. They also help preserve water resources by making treated water suitable for various applications. The following sections explain the working principles and processes of these treatment systems.

ETP Plants follow organized steps to purify wastewater. These plants target the removal of contaminants, including chemicals, oils and solid materials. The treatment unfolds through several key stages.

The treatment begins with the preliminary phase. This stage captures large waste materials and particles from incoming wastewater. Specialized screens and grit chambers extract solid waste materials. They remove items like sand, plastic and other large materials. This preparation ensures water flows smoothly through subsequent treatment phases.

Primary treatment focuses on eliminating suspended solids from wastewater. The process uses sedimentation tanks where heavy particles sink to the bottom. Treatment operators add chemicals to speed up particle clumping and settling. Clean water flows to the next stage while equipment removes settled solids. This phase significantly decreases solid waste content in the water.

Secondary treatment employs biological methods. The system introduces specific microorganisms to consume organic pollutants in the wastewater. Aeration tanks pump oxygen to support microorganism growth and pollutant digestion. This biological action eliminates harmful organic compounds. Secondary clarifiers then separate treated water from the microorganisms.

Some impurities persist after primary and secondary treatments. Advanced processes tackle these remaining contaminants. These methods ensure water quality meets the required standards. The following sections detail the advanced treatment approaches.

Tertiary treatment enhances water purity through additional steps. This phase eliminates nutrients like nitrogen and phosphorus which damage aquatic environments. The system employs filtration and chemical treatments. Operators apply disinfection methods such as chlorination or ultraviolet light to destroy remaining bacteria. These steps produce water that meets environmental release standards.

Treatment plants must process solid waste collected during earlier stages. This material called sludge needs specialized handling. Operators use thickening digestion and dewatering to process sludge. These methods reduce waste volume and enable safe disposal. Some facilities transform sludge into useful products like fertilizer.

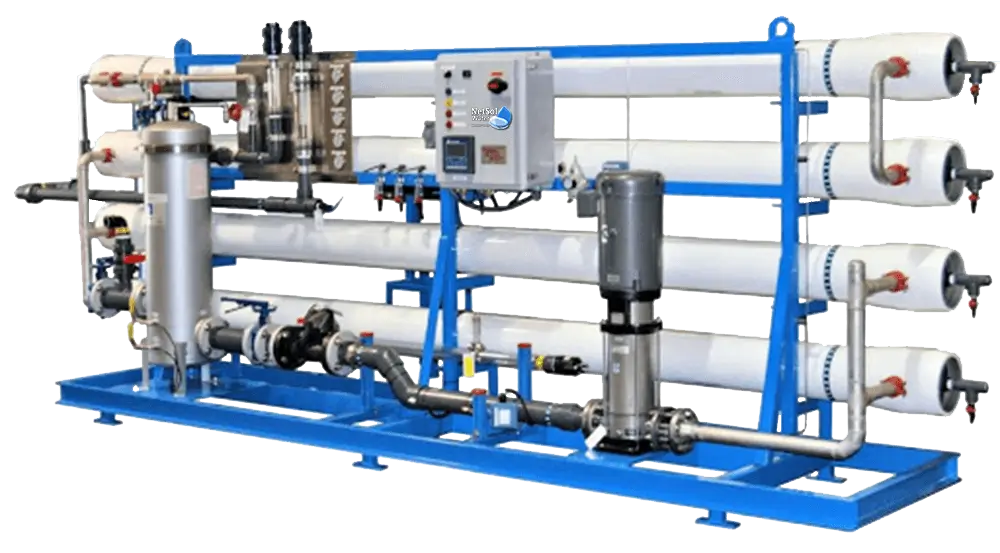

Modern treatment plants increasingly use membrane technology. Processes like reverse osmosis and ultrafiltration employ membranes to catch microscopic particles and pollutants. These advanced systems produce extremely pure water. Industries that need high-quality water particularly value membrane filtration systems.

ETP plants extend beyond basic wastewater cleaning. They actively promote environmental sustainability. These facilities help industries minimize environmental impact while conserving water resources. Consider their broader contributions.

Treatment plants prevent pollutants from contaminating natural water sources. The treatment process protects aquatic ecosystems by cleaning wastewater before release. This creates a healthier environment for all living things.

Industries reuse treated water in various processes including cooling cleaning and irrigation. This practice reduces freshwater consumption. Treatment plants enable efficient water recycling throughout industrial operations.

Environmental regulations mandate strict wastewater standards. Treatment plants enable industries to meet these requirements consistently. This prevents legal issues while demonstrating environmental responsibility.

Conclusion

Your industry needs effective wastewater management to protect the environment and maintain compliance. Our team provides expertise in effluent treatment plant solutions. We understand the unique challenges different industries face. Contact us to explore customized treatment options that match your specific needs.