What are the advantages of Coagulation and disinfection?

Each of the step in the wastewater treatment process is important to achieve the desired treatment results. However, primary and tertiary processing is important to the entire process. The pre-treatment process significantly reduces solids. Without this step, subsequent treatments will be less effective. The tertiary treatment kills or inactivates harmful microbiological substances so that the organisms encountered do not get sick.

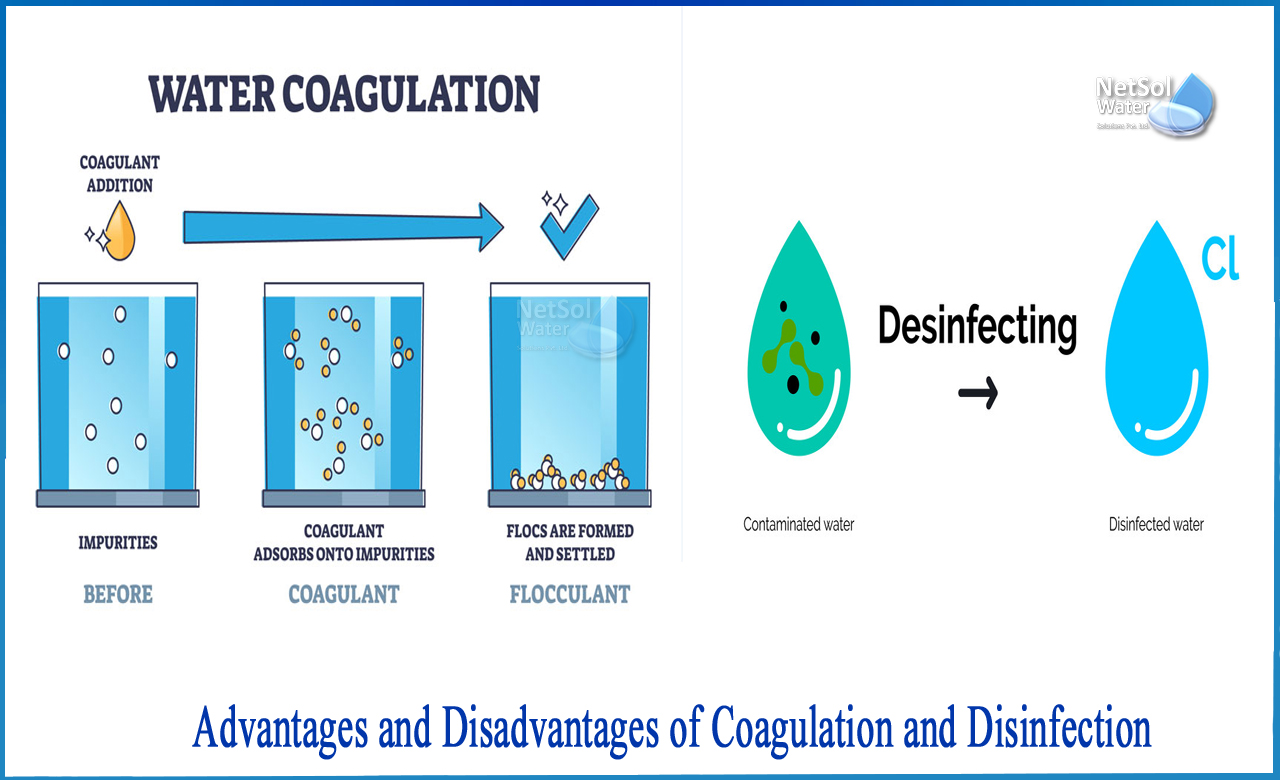

These wastewater treatment processes are coagulation or disinfection. These processes can be performed in a variety of ways, either chemically or non-chemically, each with its own strengths and weaknesses.

What is Coagulation?

Wastewater contains various levels of dissolved solids (TDS) and total suspended solids (TSS). Coarse screens and sand chambers reduce TSS, but then a more sophisticated solids removal process needs to be performed. Precipitation and filtration are methods that have been used in the past, but these methods cannot remove many of the small particles.

Coagulation has become a common method for reducing TSS and, in some cases, TDS in wastewater. This process involves de-stabilizing charged particles in solution. Due to their similar charge, the particles repel each other and prevent rapid settling. To unsettle this charge, the opposite charge must be added to the solution in order to aggregate colloids and other minerals.

What is Chemical coagulation?

Chemical coagulation is a very well-known method of particle coagulation. In this process, some chemical additives need to be added to achieve the desired destabilization condition. Alum, ferric chloride, iron sulphate and lime are some of the additives used to neutralize charged particles. Other supplements include polymers that help solids aggregate.

What are the benefits?

The main consideration when using chemical coagulation is to reduce the time it takes for solids to settle naturally. Therefore, the total residence time of the wastewater treatment process is reduced.

Chemical coagulation also helps settle finer colloidal particles and mineral contaminants. These particles usually do not settle during the settling process and pass through subsequent filtration systems.

What are the disadvantages?

Chemical coagulation is an essentially additive process. You can reduce the amount of solids in the solution, but you still need to add chemicals to achieve this.

The addition of these substances can be very complex and requires extensive testing. Dosages need to be fairly accurate for optimal and accurate treatment of inflows. Due to the different composition of the drainage source, continuous dose adjustment may be required. Adding chemicals produces large amounts of sludge that must be treated and disposed of after treatment.

This sludge is also dangerous due to the nature of the added ingredients. The amount and toxicity of sludge can increase disposal costs as it cannot be easily dehydrated.

What is Disinfection?

In third and final step of wastewater treatment, the wastewater may contain bacteria, viruses, molds, cysts, or other pathogens that cannot be removed by other treatment methods. Microbial pollutants must be inactivated or killed before draining treated water into the body of water. There are several ways to disinfect wastewater treatment, but the two most commonly used are chlorine and UV light.

1: Chlorine Disinfection

Most people are familiar with the use of chlorine compounds to treat pools with shock. Chlorine is a toxin for organisms and kills them by oxidation. It penetrates the surface of pathogens, and once inside, it begins to interact with intracellular enzymes and proteins, making them inoperable. Microbes die or do not multiply.

What is the benefit?

Chlorine is relatively inexpensive and readily available. Also, because it is a powerful oxidant, it is very effective in inactivating large amounts of harmful microorganisms in an appropriate reaction time.

What is the disadvantage?

Chlorine is highly volatile and can cause disinfection by-products (DBPs) that can be harmful to humans, animals and aquatic organisms. Careful handling is required for safe transportation, storage and use. Viruses, Giardia lamblia, and Cryptosporidium are not attacked by chlorination.

2: UV Disinfection

The UV light disinfection system has recently become widely used in many applications due to its non-chemical disinfection capabilities. At certain wavelengths, UV light can destroy the pathogen's DNA by breaking its molecular bindings. In this condition, normal cell function is disabled, and as a result, microorganisms, cysts, and viruses remain virtually inactive.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.