The process of preparing water for human consumption or other uses is known as water treatment. While there are a number of important factors to consider, sedimentation water treatment is particularly important. To guarantee that the water treatment process is conducted safely and efficiently for the general public, it is critical to have a thorough understanding of the entire process.

What is sedimentation process in Sewage Treatment Plants?

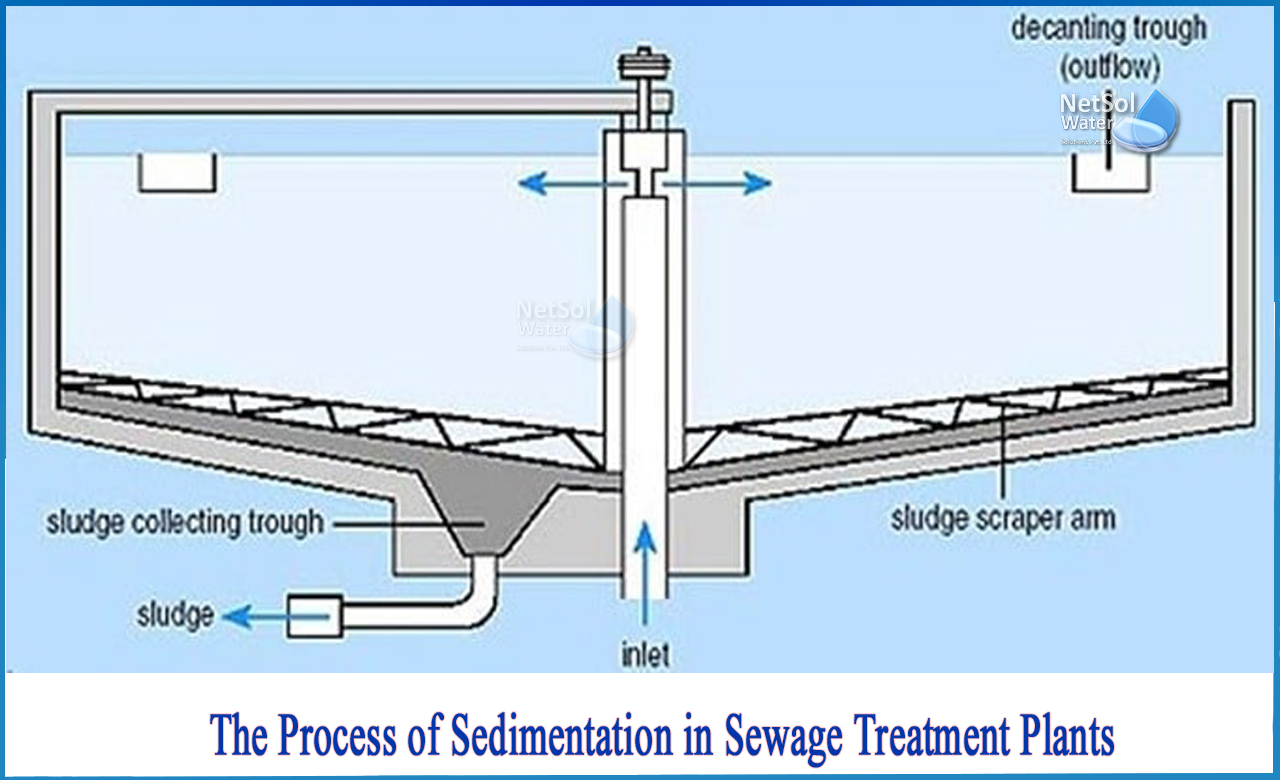

The process of sedimentation is the separation of tiny particles and sediments in the water. When the water is quiet, gravity pulls the heavier sediments down to produce a sludge layer, which occurs naturally.

Sedimentation tanks are designed to decrease the velocity of water flow so that suspended particles settle due to gravity's influence.

Benefits of a Sedimentation Tank:

1. It is a low-cost, easy-to-use water pre-treatment system.

2. It is low-cost to operate and can manage a wide range of flows.

3. Coagulants shorten the time it takes to settle suspended particles.

4. It has high efficiency of clarifying and is sludge-removal friendly.

Types of Sedimentation in Water Treatment:

1. Plain sedimentation

Plain sedimentation occurs when suspended particles are separated solely by gravity.

2. Sedimentation with coagulates

Plain sedimentation does not remove fine suspended particles or colloidal contaminants. In ordinary sedimentation, particles with a diameter of 0.006 mm or less take 10 hours to settle.

As a result, some chemicals must be added to the water to remove contaminants that are not eliminated by simple sedimentation. Coagulants are the chemicals involved, and the process is known as sedimentation with coagulation.

Types of Sedimentation Tanks:

Sedimentation tanks could be categorized as follows:

1. Depending on the operation methods

a. Fill-and-drain tanks

In this case, water from the intake is kept for a period of time in the fill and draw sedimentation tank. During this time, the dispersed particles settle at the tank's bottom. The water is drained out of the outlet after 24 hours

b. Continuous-flow tanks

Water is not allowed to rest in this instance. Flow occurs at all times but at a relatively slow rate. Suspended particles settle to the bottom of the tank during this flow.

2. On the basis of form

a. A circular tank

For continuous vertical flow sedimentation tanks, circular sedimentation tanks are suggested. In this scenario, the influent is routed through the tank's central pipe, resulting in a radial flow.

b. A rectangular tank

Rectangular sedimentation tanks are the most popular and commonly utilized sedimentation tanks. In rectangular tanks, the wastewater flows in a horizontal, lengthwise direction. For rectangular tanks, baffle walls are sometimes used to prevent short-circuiting.

c. Hopper’s bottom

A deflector box is situated at the top of the hopper bottom tank, which deflects the influent coming from the central pipe downwards. Sludge collects at the bottom and is pumped out using a sludge pump.

Use of Sedimentation in Sewage Treatment Plants (STP’s):

1. Before biological treatment, the sewage goes through simple sedimentation, and after biological treatment, it goes through sedimentation with coagulation. Chemical Precipitation refers to the sedimentation and coagulation process.

2. Sedimentation is a critical step in the sewage treatment process. The majority of sewage treatment is done as primary treatment, while activated sludge units are used in some cases.

3. The goal of sewage sedimentation is to separate the settleable materials so that the settled sewage does not form sludge banks when released into waterways.

4. Screening or skimming does not remove fine suspended particles. These suspended materials are removed using the sedimentation process, which involves allowing sewage to sit idle in sedimentation basins.

5.Following the screens and grit chambers are the sedimentation tanks, often known as plain sedimentation or primary settling tanks. Secondary settling tanks, also known as secondary sedimentation tanks, are used to settle effluents following secondary treatment operations when the flocculated solids produced by biological treatment are eliminated.

Thus, sedimentation plays a vital role in the primary segregation of the wastewater effluents

We at Netsol Water design, manufacture, and install STP of various kinds and sizes

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.