What is an oil water separator?

An oil–water separator is a device used to separate crude oil and suspended particles from industrial wastewater generated by oil refineries, petrochemical facilities, chemical plants, natural gas processing plants, and other industrial oily water sources.

Oil water separators can effectively remove gasoline, diesel fuel, crude oil, vegetable oil, and practically any other oil that is lighter than water. Oil/water separator effluent is normally dumped to either a sanitary sewage system or a storm sewer. Oily water separators, when properly designed, constructed, and maintained, provide a treatment system for treating oily wastewater that prevents unacceptable levels of pollution from entering a storm sewer or sanitary sewage system.

What is the purpose of an oil water separator in wastewater treatment?

While water and oil naturally separate in some situations, this process does not function as well with wastewater. Because wastewater contains a range of pollutants, oil particles become entangled and do not always separate spontaneously.Oil water separators prove to be very helpful in this scenario.

Characterization of the structure and its function:

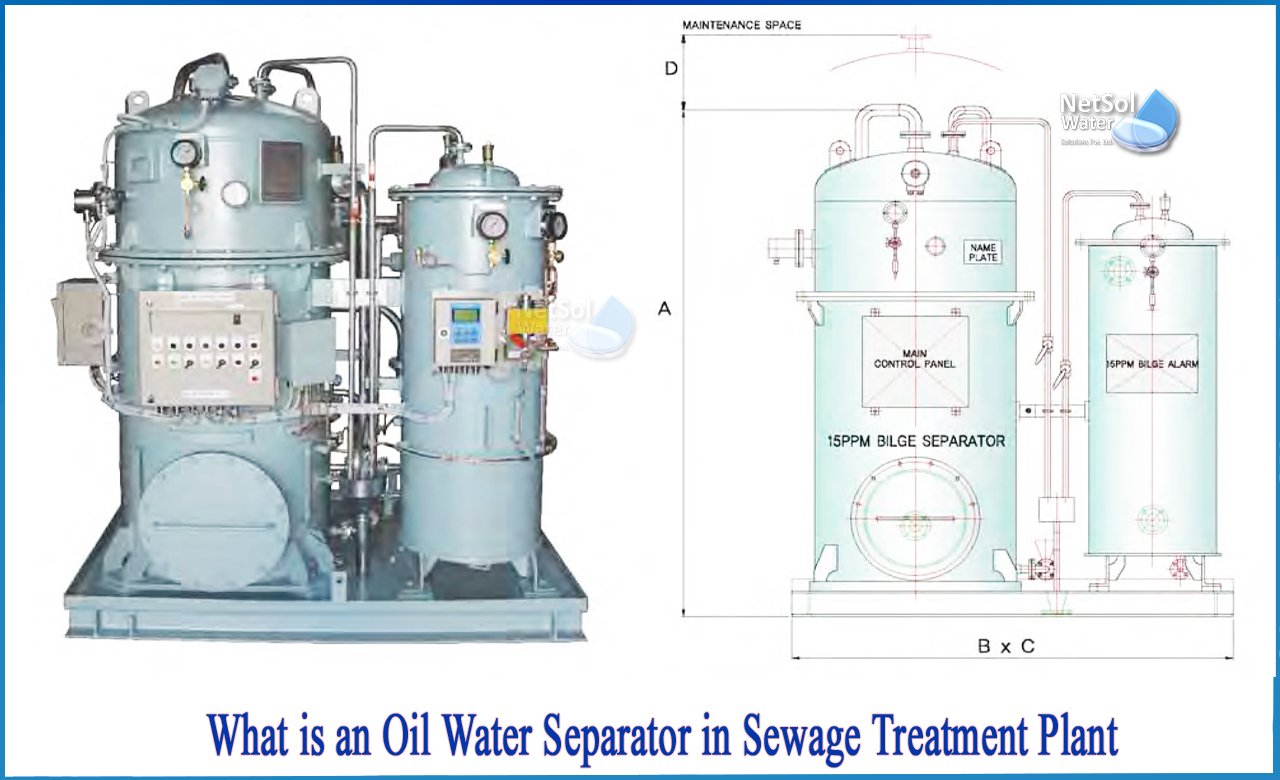

The Oil Water Separator is a gravity separation device that use Stokes' law principles to determine the rise velocity of oil droplets depending on density, size, and water qualities. The separator's design is based on the specific gravity difference between oil and wastewater, which is substantially lower than the specific gravity difference between suspended particulates and water.

According to that design requirement, the majority of the suspended particles will settle to the bottom of the separator as a sediment layer, the oil will rise to the top, and the wastewater will be the intermediate layer between the oil on top and the solids on the bottom. When successfully used, the Oil Water Separator Design Standards alter the geometry, design, and size of the separator beyond fundamental Stokes Law principles.

Allowances for water flow entrance and exit turbulence losses, as well as other considerations, are included. A minimum length-to-width ratio of 5:1 and a minimum depth-to-width ratio of 0.3:0.5 are required by the Oil Water Separator Specification. The oil layer, which may contain entrained water and associated suspended particles, is typically skimmed off continuously in the operation of Oil Water Separator separators.

This removed oily layer can either be reprocessed to recover valuable goods or discarded. A chain and flight scraper (or similar equipment) and a sludge pump are used to remove the heavier bottom sediment layer.

Types of oil-water separator:

Below ground oil water separator:

-Free oil droplets as tiny as 40 microns are removed by the below Ground Oil Water Separator.

-Reduces the concentration of free oil in the effluent to 10 PPM.

-Excellent for auto businesses and vehicle wash structures.

Above ground oil water separator:

Above-ground oil water separators separate free and mechanically emulsified oils at speeds ranging from 2 to 70 gallons per minute.

Products for oil-free polymeric filtration:

All Oilfree filter cartridges and associated technologies use polymeric surfactant technology. Hydrocarbons, emulsified contaminants, oily sheen, manufactured and natural oils, solvents, and biologically bound metals are all removed by the Oilfree surfactant solution.

Some other products:

-Eliminates mechanically emulsified oil and grease, free oil, and organic compounds with a high molecular weight.

-Very adaptable and successful, and may be employed in pre-treatment, post-treatment, or stand-alone procedures for oily water separation.

For more details, contact Netsol Water.