How to Choose Between MBBR and SBR Technology in STP Plant?

Sewage Treatment Plants use various technologies to treat wastewater effectively. Two of the most popular and advanced technologies are Moving Bed Biofilm Reactor (MBBR) and Sequencing Batch Reactor (SBR) technologies. Both offer their respective advantages and use in terms of the type of wastewater, space availability, and cost.

Here, we will explain the key features of MBBR and SBR technology in STPs and provide guidance on choosing the most suitable one for you.

What is MBBR Technology?

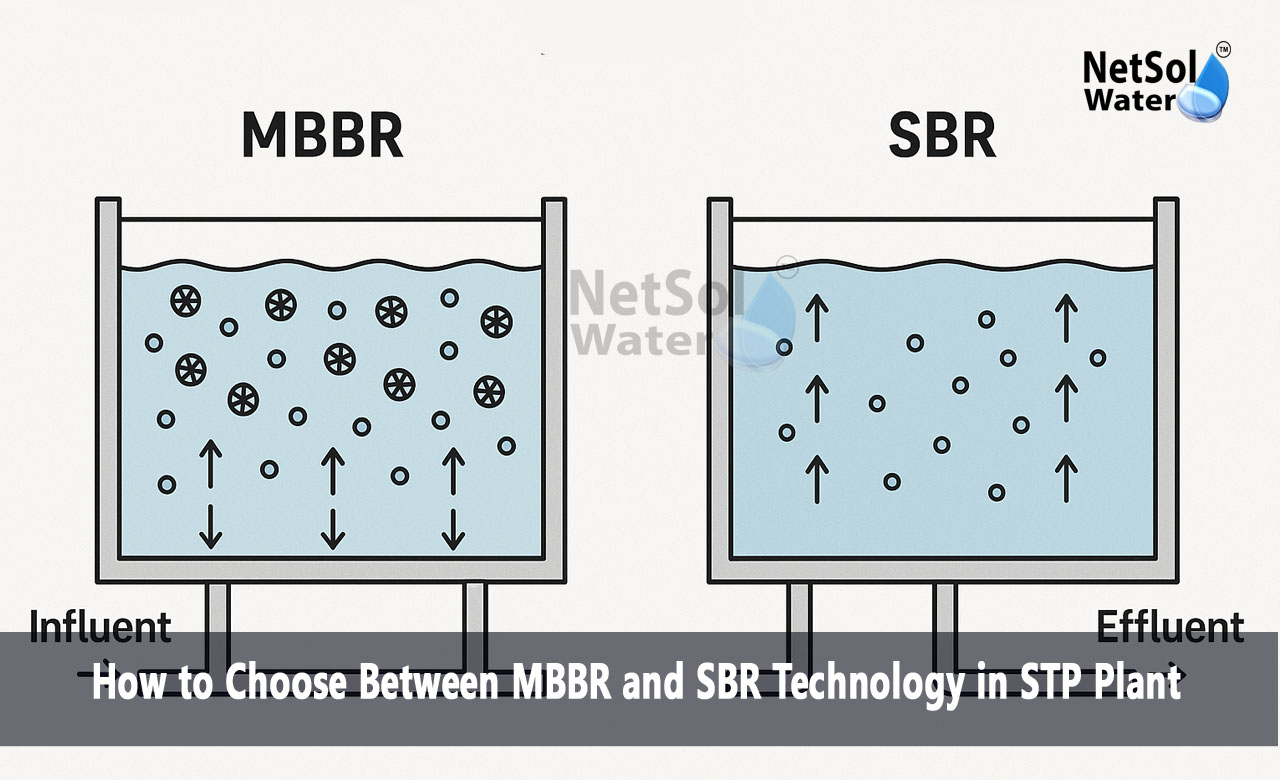

MBBR is a biological treatment process that employs small plastic carriers (media) suspended in a reactor. The carriers provide a high surface area for the growth of beneficial bacteria that can biodegrade organic matter. The carriers are continuously circulated, and this enhances contact between wastewater and bacteria.

What is SBR Technology?

SBR is batch wastewater treatment in which wastewater passes through scheduled stages in a single reactor tank. Filling, aeration, settling, and decanting stages are incorporated. Staged treatment makes the process capable of flexible operation and efficient removal of contaminants in cycles.

Factors to Consider When Choosing Between MBBR and SBR Technology in STPs

Availability of Space

When there is limited space, MBBR and SBR technology in STPs work otherwise. MBBR requires less space because it treats water all the time with suspended carriers, while SBR needs a larger tank because it handles batch processing.

Wastewater Type and Quantity

The quality and quantity of sewage dictate the technology to be employed. MBBR fits best in situations of continuous steady flow and can handle variable loads better. SBR is suited where the inflow of wastewater is variable or where there is a need for improved nutrient removal.

Level of Complexity and Control

SBR systems require greater control over treatment cycles, with operation being rather more sophisticated. MBBR is continuously always and normally easier to control. Availability of trained operators could affect the choice.

Maintenance and Cost

MBBR will often have lower operating costs and reduced sludge handling since less sludge is produced. SBR systems may have increased maintenance costs due to pumps, valves, and timing devices employed during batch treatment.

Goals of Treatment

For those crops which need more removal of nutrients such as nitrogen and phosphorus, SBR technology may provide better results due to controlled aerobic and anoxic conditions. MBBR can be highly effective in removing organic matter but may require additional treatment for nutrients.

Advantages of MBBR and SBR Technology Used in STPs

Advantages of MBBR:

1: Cost-effective design feasible for small to medium installation.

2: Unstable biological process with lesser clogging hazard.

3: Easy to install into existing plants.

4: Low sludge production reduces disposal expense.

SBR benefits:

1: Flexibility to handle variable influent.

2: High organic and nutrient pollutant removal.

3: No specialized sedimentation tanks are needed.

4: Automated cycling provides better process control.

Conclusion

Choosing between MBBR and SBR technology in STPs depends on many factors such as space, wastewater quality, operational expertise, and treatment goals. MBBR is a low-space, low-maintenance technology suited for continuous flow schemes, while SBR is more adaptable and has improved nutrient removal capabilities through batched treatment.

Awareness of the strengths and weaknesses of each technology allows for an informed decision. Focusing on small size, simplicity, or removal of nutrients, the right technology selected will yield good sewage treatment and harmony with the environment.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-9650608473

Or write us at enquiry@netsolwater.com