The railways are among the most affordable and environmentally friendly sources of transportation, and managing waste is one of the crucial elements in moving the railroads towards a sustainable transportation network. Management of sewage is a key component of the Railways' plan to raise the caliber of its transportation services. The Railways, in addition to facilitating the passage of people and goods, also maintains sizable employee residential colonies at various points along its network. Together, they use significant amounts of resources and produce significant amounts of sewage in the railways' traction and non-traction activities.

In order to ensure the secure disposal of wastewater from railway stations, sewage treatment facilities (STPs) are an essential element.

In this blog, we'll go through how to design a STP for Indian railway stations, complete with design calculations, process flow diagrams, and working functions.

Design considerations of STP for railway station:

The design of a STP for railway stations depends on both the amount and the quality of sewage produced. The number of passengers utilizing the station each day determines the sewage flow rate. According to estimates, each person uses 135 litres of water on average each day, with sewage accounting for 80% of that amount. Consequently, the following formula can be used to determine the sewage flow rate:

Sewage flow rate = Number of passengers x 135 x 0.8

The capacity of the plant can be computed based on its required treatment efficiency once the sewage flow rate has been established. The following guidelines for the discharge of treated sewage from railway stations have been established by the Central Pollution Control Board (CPCB):

30 mg/l of suspended solids and 30 mg/l of biological oxygen demand

Coliforms (TC): 5000 MPN/100 ml Total Coliforms

Based on these requirements and the sewage flow rate, the STP's design capacity is determined. Usually, 80–90% of the sewage produced may be treated by STP.

Working function of ETP for railway station:

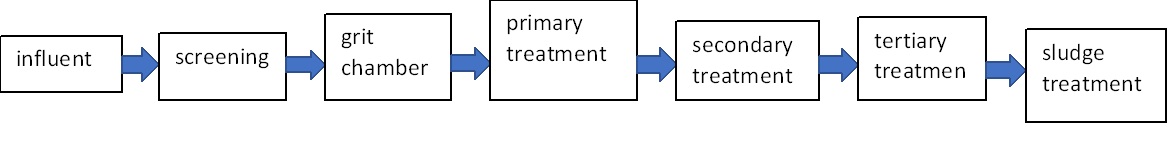

1. Preliminary treatment: The STP receives sewage collection from the train station. Large objects are first removed from the sewage using a screen, and then sand and gravel are removed using a grit chamber. Skimming tanks are used to remove oils and grease.

2. Primary treatment: Following preliminary treatment, the sewage is run through a primary settling tank, where heavier solids float to the surface and the heavier solids sink to the bottom. Typically, sedimentation in settling basins is used to achieve this.

The primary therapy and the preliminary treatments may occasionally be grouped together. In initial treatment, the organic materials are sorted out in sedimentation tanks and are frequently stabilized by anaerobic decomposition in a digestion tank or are burned.

3. Secondary treatment: The effluent from the primary settling tank undergoes treatment in a biological reactor, in which bacteria and other microorganisms break down the organic matter and eradicate nutrients. Depending on the treatment technology, microorganisms carry out these actions in a controlled anaerobic or aerobic procedure.

4. Advanced Treatment: Also known as Tertiary Treatment, this procedure involves eliminating the organic load that remains after the Secondary Treatment, with a focus on eliminating the pathogenic germs. This treatment, which is typically done through chlorination, is usually done to sterilize the water.

Process flow chart of ETP for railway stations

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com