How does CIP affect the treatment of wastewater?

Food and beverage makers are dedicated to food safety, which involves adequate sanitation and Clean in Place (CIP) processes. When these principles are followed consistently, the company's safety measures improve significantly. The issues inherent in food production safety are mitigated if the equipment and facility fulfil clean criteria at the start of each run.

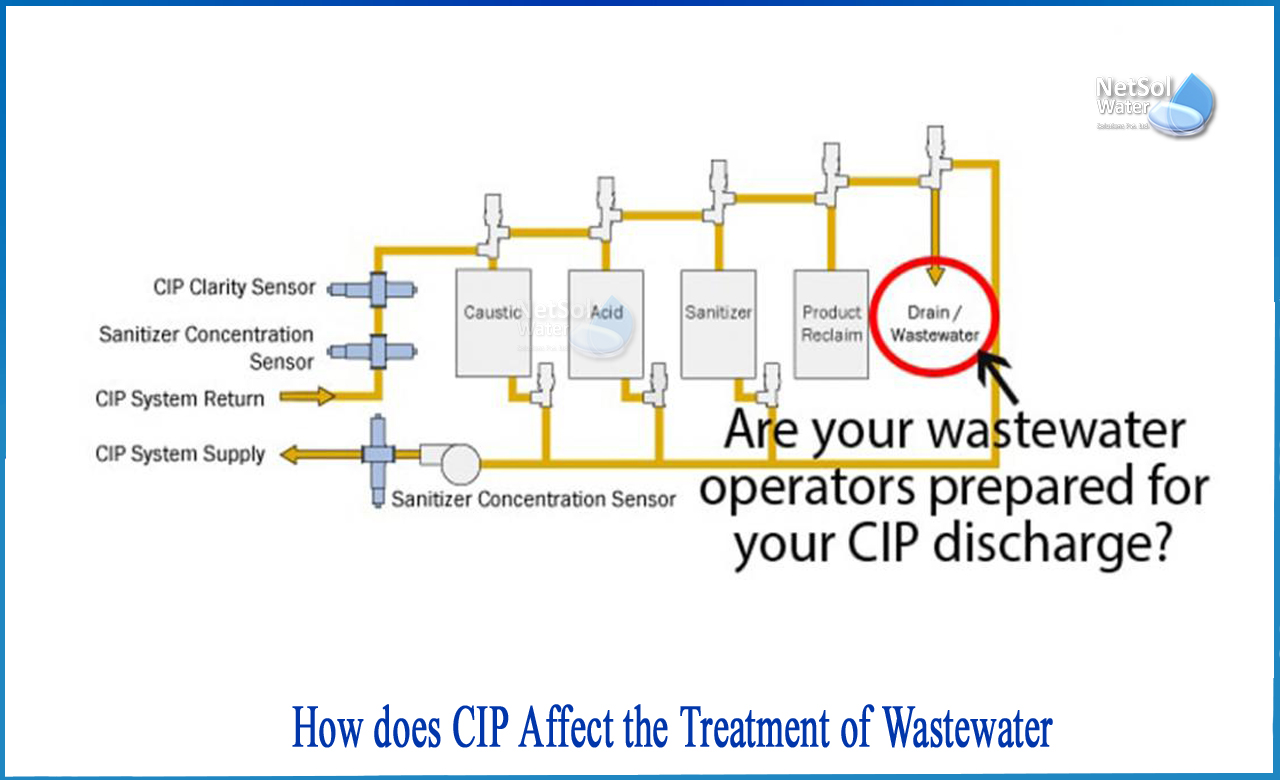

As a result, when wastewater operators are informed and taught about sanitation and the CIP process, suitable wastewater treatment procedures are employed, assisting in the achievement of sustainability goals.

What exactly is CIP?

CIP is a closed system in which a recirculating cleaning solution (typically sprayed with nozzles) cleans, rinses, and sanitizes equipment’s. The CIP system is often automatically regulated, and cleaning sequences are assigned the best timing for efficient cleaning of all plant sections. CIP systems clean all sorts of process plants quickly, efficiently, and consistently.

CIP systems are classified into the following operations:

1- Flushing: to get rid of residues

2- Alkaline cleaning procedure: alkaline detergents breakdown fat and proteins and clean areas where tougher deposits have formed

3- Rinse: with intermediate water

4- Acidic cleaning operation: to neutralize the caustic residue on the plant's surfaces. The acidic detergents clean the equipment of mineral deposits (especially warm areas like in the pasteurizer)

5- The last water rinse: removes any remaining acid solution with cold water.

The Best Sanitation Practices

Having well-trained personnel is one of the most critical parts of sanitation and wastewater treatment. Maintenance professionals, as well as those responsible for end-of-production housekeeping, must understand how their operations influence sanitation efforts, in addition to sanitation and wastewater personnel. Understanding the connection between their activities and cleanliness, as well as monitoring and reinforcing optimal practices, helps to foster a culture of rule-following.

Sanitation excellence is comprised on five fundamental components:

- Evaluation of environmental variables

- Continuous enhancement

- Use of constant, everyday sanitation practices

- Sanitation on a regular basis, such as tear down and heating

- Validation of efficient sanitation

CIP has an impact on wastewater treatment

What ha?ppens on the facility floor does not necessarily have a straight relationship or link with how it influences wastewater treatment! They are, nonetheless, related.

To clean equipment in most food and beverage and pharmaceutical establishments, chemicals such as chlorine, caustic soda, phosphoric and nitric acids, sodium hypochlorite, and peracetic acid (PAA) are employed.

This water is then released for treatment, causing changes in pH, flow rates, and temperatures. This brings with it new issues for wastewater operators. As a result, sanitation and wastewater operators must interact on a frequent basis in order to increase the treatment process's performance. Wastewater operators must be aware of when sanitation procedures take place, the chemicals employed, and the volume of water used.

The Consequences of Not Optimizing CIP

If your facility does not maximize CIP, your whole wastewater system may be jeopardized. Undersized equalization tanks may be in place if the greater flow rates during CIP and sanitation are not taken into consideration, resulting in unsatisfactory wastewater treatment.

Contamination loading rates are thus underestimated or predicted for normal output, and treatments are not completely optimized since the larger initial contaminant load is not compensated for during sanitation and CIP.

If the facility does not have a flow meter, it is possible that water and chemical use will be underestimated or overestimated. Data is generally imprecise without the precision that excellent sanitation procedures and CIP can provide, making it difficult to build a sustainability plan.

Conclusion

CIP processes are typically performed at the same time every time.

Netsol Water is focusing on automation capabilities that can effectively and efficiently manage wastewater during the facility's CIP procedures, using correct wastewater sampling and testing to identify the pattern.

Not only that, but we can install flow meters to monitor real process flow, conduct 24-hour composite sampling and testing of wastewater, and examine pH control loops and appropriately sized equalization equipment.

We believe in developing simple and practical integrated wastewater solutions. Our comprehensive approach to wastewater treatment involves design, installation, and servicing, as well as delivering the appropriate chemicals and optimizing chemistry dose.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.