Introduction:

Water is a crucial component of domestic use and manufacturing industry operations. In businesses, water is used as a solvent, coolant, and in a variety of other chemical-based processes. Wastewater is a byproduct that is created after the production process is finished. Then, this pollution is referred to as effluent. Both toxic and non-toxic elements are present. Because of the toxic substances it includes, effluent cannot simply be disposed of into the surroundings.

As a result, an effluent treatment plant is necessary. Simply stated, this is a process used to clean industrial wastewater so that it can be recycled or disposed of safely. Due to the variations in the chemical composition of their wastewater, various businesses require relatively distinct effluent treatment facilities.

Composition of wastewater from the printing press:

Synthetic dyes are widely used in the textile, printing, leather tanning, cosmetic, pharmaceutical, and food manufacturing industries. Among industrial areas, it is one of the most polluted. The printing technique is quite versatile and can be applied to a wide range of materials, including paper, fabrics, plastic, and others.

After the printing process is complete, a number of compounds, including ethers, alcohols, phenols, aldehydes, ketones, benzene, and esters, are used in the cleaning procedure. The fact that the resultant effluent frequently includes a variety of solvents, surfactants, dyes, and other compounds further increases the difficulty of treating wastewater.

Inadequately disposing of printing wastewater into water bodies has a wide range of effects, from aesthetic issues to the eventual extinction of the aquatic environment due to light attenuation, oxygen consumption, and toxicity effects. Therefore, it is critical to investigate and develop methods for printing wastewater remediation.

Working of an ETP for printing Press with the help of flow diagram:

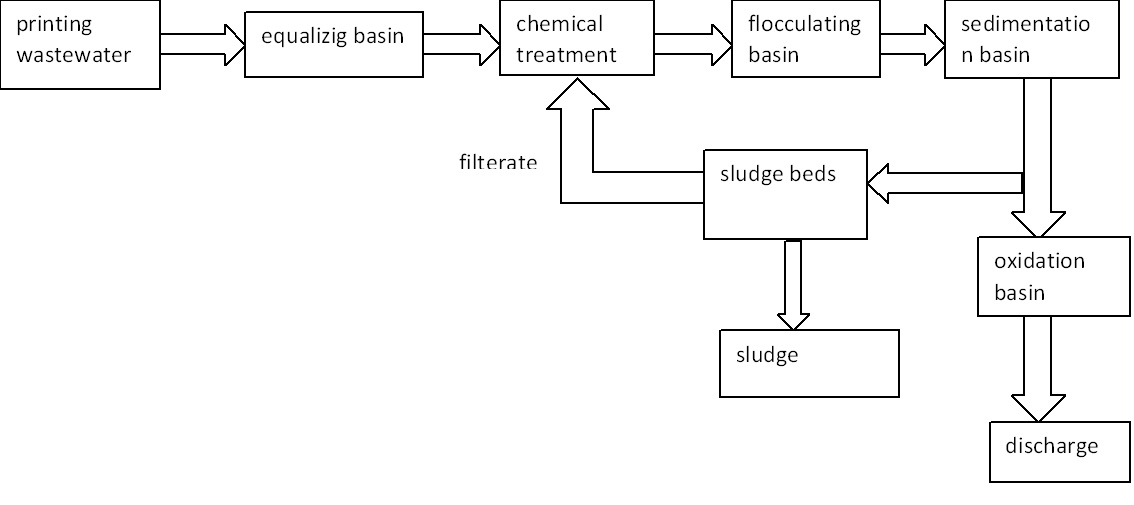

Aqueous ink can be separated from the contaminated industrial wastewater that results from the industrial process by the technology used to treat the wastewater generated by the printing industry. The treatment method involves chemical stabilization, precipitation, and sedimentation, followed by filter press filtering and dewatering.

The wastewater that the production plant constantly discharges is homogenized in a storage plant, where it is agitated with a slow-speed stirrer and pumped via a pipe mixer to a coagulation-sedimentation reactor. The effluent always has about the same level of pollution after homogenization.

Wastewater is alkaline stabilized to the necessary pH level in the pipe mixer. By dosing coagulant, pollution is separated from effluent through precipitation. In order to meet the requirements for water released into the sewerage system, it is ensured that wastewater will be neutralized to the necessary pH value in this manner.

By adding organic flocculant, the filter press's filtering capacity can be improved, as well as the dewatering of precipitated products. The processed wastewater satisfies the standards for biological wastewater after-treatment in a biological wastewater treatment facility.

Advantages of an effluent treatment plant:

ETP significantly reduces environmental harm while also generating advantages for the sector. There are numerous benefits of ETP, and the following are the best five:

1. It can guarantee that you are following all environmental laws and regulations.

2. It recycles or transforms waste water into pure, secure, and useful water.

3. It is the best method to lessen waste generated on your property.

4. It helps the ecosystem by eliminating dangerous pollutants and contaminants.

5. A properly kept ETP will enable you to make long-term financial savings.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com