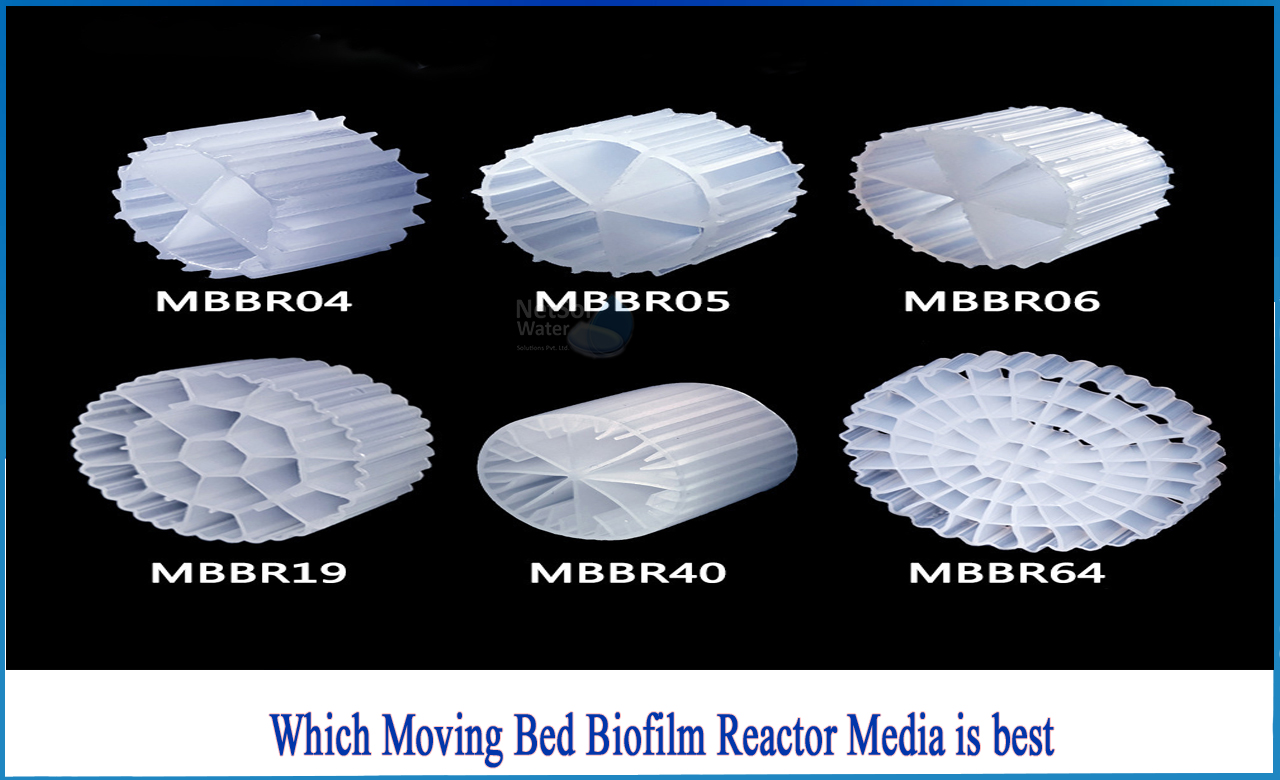

Which Moving Bed Biofilm Reactor media is best?

Moving bed biofilm reactor (MBBR) media systems provide high-quality, low-cost, and low-maintenance secondary wastewater treatment options. With so many different media types to select from, determining the proper MBBR media specification for a certain wastewater treatment tank can be difficult.

In this blog, we will describe the MBBR method and go through MBBR floating media in depth, and show how to pick the best amongst several MBBR media types.

What is MBBR media's purpose?

A bed of MBBR media is made up of thousands of microscopic fragments that dangle themselves throughout a wastewater treatment tank, taking up around half to seventy percent of the available area. Their architecture makes them ideal for fostering the development of beneficial microorganisms. The spokes of several forms of MBBR media resemble wheel-shaped pasta, offering excellent surface area for bacterial growth. Others are tiny discs or squares in the shape of coins.

Aeration tanks benefit greatly from the usage of MBBR media carriers. Their microorganisms help digest the solid waste as they distribute around the tank. The media are particularly successful because their design provides a large surface area for helpful microorganisms to settle on, increasing the number of bacteria available to digest waste.

How do the MBBR medias work?

1: The small MBBR pieces disseminate throughout the wastewater in an aeration tank, and their enormous surface area creates a favorable habitat for microbial development. The wastewater in the tank is decomposed by the biofilm that forms on the medium.

2: Diffusers deliver oxygen to the tank to encourage ongoing microbial growth, while a mesh filter keeps the media carriers from being washed away with the effluent. Because the density of MBBR media carriers is equal to that of water, they mix well with wastewater and facilitate consistent waste digestion.

3: The usage of MBBR media is particularly useful since these particles take up little space, are simple to maintain, and efficiently digest wastewater. Changes in the volume and kind of waste in the water can also be automatically adjusted by the microorganisms on the medium.

What are the different MBBR media types?

The following are some of the several MBBR media types:

1: Sponge-type MBBR media:These carriers offer great mechanical strength, a large specific surface area, and a rough surface roughness that biofilms prefer to adhere to. Their spongy materials are extremely flexible, yet they wear out more quickly than other materials.

2: Chip-type carriers:They are very thin and feature a high concentration of tiny pores. They are very flexible and have a high resilience to wear and strain.

3: Coin-shaped carriers: Thin, coin-shaped media carriers have the benefit of allowing wastewater to pass into them from both sides of the media, making them less vulnerable to fouling.

4: Tube-shaped carriers: Long, thin tube-shaped carriers provide a larger surface area for microorganism growth on the MBBR medium. Their form also allows them to float in the water column equally rather than piling on top of one another. However, because of their hollow nature, they are sometimes prone to fouling.

How do I choose the best MBBR media?

You'll want to think about a few things while choosing the right moving bio bed medium for your wastewater applications:

1: Surface Area of the Media

In general, a wastewater treatment plant should maximize media surface area while ensuring that the media carriers' other qualities fulfil the facility's requirements. For example, MBBR media carriers in the shape of spoked wheels provide a large surface area for their size, allowing a facility to satisfy its waste digestion requirements.

2: Performance and Biodegradation rates required

Plants should search for MBBR media carriers of the suitable shape and material quality to enable efficient, effective waste digestion in order to maximize performance and biodegradation rates.

3: Design and Form

The MBBR media carriers should be designed to have a density that is similar to that of the wastewater. The proper density guarantees equal dispersion throughout the tank and complete waste digestion. Varied materials have different densities – for example, more cost-effective re-granulates may have significant density variations across carrier sections, whereas polyethylene may give better uniformity.

4: Resistance to Wear

The wear-resistant properties of MBBR media carriers affect how well they withstand wastewater treatment demands. Media carriers that are more resistant to wear and tear endure longer and require fewer repairs over time. Some MBBR media carriers, such as sponges, have low abrasion resistance and so wear out more quickly. Chip-type carriers are more resistant to damage and have a longer lifespan. The insides of tube-shaped variants are prone to biomatter accumulation, which eventually dies and prevents active waste digestion.

5: Maintenance

MBBR media systems have a low maintenance need. Some materials, such as polyethylene, last longer than others and require less maintenance, therefore facility managers should research alternative materials and establish how long the plant's medium must endure.

Make Netsol Water your trusted provider to reap the benefits of a high-quality MBBR system in your wastewater treatment plant. Advanced hydrodynamics, aeration, media construction, and biofilm in WWTPs improve wastewater treatment efficiency, minimize maintenance, and enable a facility reach its specific wastewater treatment goals.

You may reach us via phone at +919650608473 or by email at enquiry@netsolwater.com.