Concept of Zero liquid discharge (ZLD)

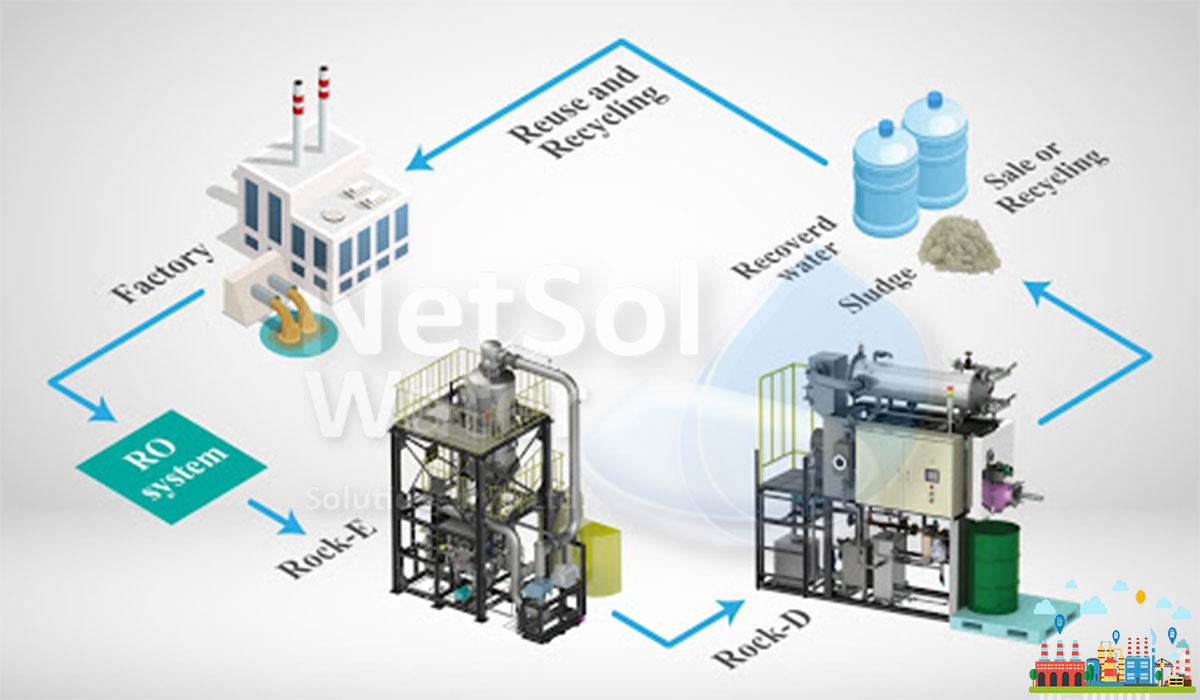

Zero liquid discharge wastewater treatment is a process that recycles and purifies all the wastewater for reuse. At the end of the treatment cycle, it leaves zero discharge. It is a kind of advanced wastewater treatment that includes reverse osmosis, ultrafiltration, evaporation, and fractional electro deionization.

ZLD is a one-stop solution for treating dangerously contaminated water. It treats the wastewater and transforms it into desirable, high-quality effluent suitable for various applications such as landscape irrigation and industrial processes. Thus, it contributes to conserving precious fresh water resources.

This approach is highly driven by many considerations that include compliance with the stringent regulations, high cost of freshwater, high stewards of dwindling water supplies. If any organization adopts zero liquid discharge technology, it can immensely benefit as it adds to a positive perception of its brand.

The technology seeks to achieve more negligible environmental impacts and reduce water demand competition as the strength of freshwater increases, and it strengthens all-important local community relationships.

The technologies used in ZLD are sedimentation, dissolved air floatation, biological treatment, media filtration, activated carbon filtration reverse osmosis, and ultrafiltration. Besides, it also offers many technologies depending upon the quality of water, such as desalinated water.

ZLD's working principles

As we understood above, ZLD technology uses various facilities such as sedimentation, DAF, media filtration, activated carbon filtration, ultrafiltration, and reverse osmosis. Now, we will understand how these facilities work step by step.

Removing the coarse particles and sediments from the wastewater is the first and crucial step. This helps in protecting the membrane and other equipment by preventing its fouling due to coarse particles. In sedimentation, the suspended solids get settled at the bottom due to the gravity principle. Afterward, the DAF helps in the removal of various colloidal materials and dispersed particles.

The water then left is used to remove solids that remain after the floatation stage. The dissolved organic material is ultimately disposed of and completed with the help of activated carbon filtration followed by ultrafiltration. The last step of the ZLD process ensures that the residual suspended solids, colloids, and organic matter, including microorganisms such as bacteria, viruses. They are treated before the water passes through the RO (reverse osmosis) unit. The final step remains to check whether dissolved solids and metals are removed from the water or not. It is to be noted that it would not be possible to reuse the water until released.

Netsol Water incorporates the latest technology that conforms to the predefined industrial standards and quality. Therefore you don't have to worry about the quality and services. We are one of the most cost-effective companies committed to preserving water. We deal in the best sewage treatment plants but are not limited to them only.

Contact us to discuss your requirements. We can be reached at 9650608473, or feel free to leave your query at enquiry@netsolwater.com.

-wastewater-treatment-NetsolWater.png)