What is the purpose of installing ETP in hospitals?

The proper treatment of hospital wastewater is critical. You must be thinking that what is the purpose of installing ETP in hospitals! Why?

If the hospital effluent is not adequately handled, it can have a harmful influence on the environment and human health. As a result, selecting an appropriate treatment technology, known as an effluent treatment plant for hospitals is critical.

The primary goal of an Effluent Treatment Plant (ETP) is to remove as many suspended particles and organic matter, from effluent before it is released back into the environment, or reused for other hospital functions. When untreated wastewater contaminates groundwater, it poses substantial health hazards by generating serious infectious illnesses, in those with compromised immune systems.

Hospital Effluent Treatment Plant

Hospitals discharge a large amount of wastewater that contains a variety of pollutants, including, antibiotic-resistant bacteria, viruses, etc. If this wastewater is not cleaned effectively, the effluent will come into direct contact with groundwater. It will contaminate it, posing a risk to human health, and hence the environment (air, soil, and water).

Understanding the complexities associated with hospital effluent treatment, Netsol Water, designs an efficient and effective effluent treatment plant to treat this effluent, in complete compliance with environmental and other regulations. We provide modern, customized facilities with exceptional operational reliability, guaranteeing optimal energy use.

Sources of Effluent Genrated in Hospitals

Hospital effluent is created by many hospital departments, such as patient wards, surgery units, clinical wards, ICU, kitchen, and laundries, and has a very diverse composition depending on the activities involved.

Hospital effluent also contains pharmaceuticals, radionuclides, detergents, antibiotics, antiseptics, surfactants, solvents, medicinal medications, heavy metals, radioactive substances, and potentially dangerous and drug-resistant microbes.

The following are some of the hospital units that create effluent:

- 1. Patient wards & administration unit

- 2. Kitchen/canteen and laundry

- 3. Operating rooms and ICUs

- 4. Radiology & dialysis section

- 5. Laboratories

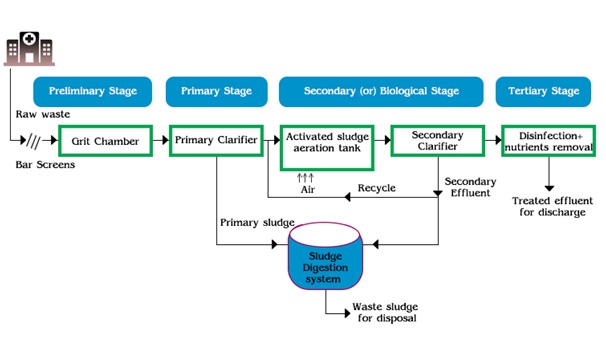

Flow chart of ETP for Hospitals

Stage 1: Preliminary

This stage, often known as pre-treatment, is the most important treatment phase in the majority of ETPs. It employs bar screens of various shapes and sizes, to remove large sized suspended particles such as paper, plastics, metals, trash, rags, and other materials from entering raw wastewater. These materials may cause significant harm to plant equipment’s, if they are not eliminated. When wastewater enters a grit chamber, it slows the flow of water and thereby removes sand, grit, and sand stones, a process known as sedimentation.

Stage 2: Primary Level

It employs physical and chemical approaches to enhance the wastewater quality. When wastewater enters a sedimentation tank or primary clarifier, larger solid particles settle to the bottom of the tank, while lighter particles float to the surface and are skimmed off, using a process known as skimming. It eliminates 60-65% of total suspended solids from liquid wastewater. This stage may include the use of a grit chamber to remove grit. The settled material is referred to as primary sludge, and it is sent to a sludge digester for further processing. The partially cleared water now advances to the next step.

Stage 3: Secondary Level

This is the stage utilizing biological treatment procedures. 80-90% of organic materials are removed.The majority of hospital ETPs employ the "activated sludge method," in which liquid wastewater enters an aeration tank, where it interacts with air to stimulate the development of bacteria, and hence the breakdown of organic materials. When aerated water enters a secondary clarifier, floatable debris is removed, while heavier matter settles to the bottom, resulting in "active sludge" or secondary effluent.

A portion of the sludge that still includes bacteria will be re-circulated back to the aeration tank, to speed up the breakdown of organic waste. The remaining bacteria are dealt with individually in the next stage, disinfection.

Stage 4: Tertiary level

This is the final stage, which is also known as the disinfection stage. This stage eliminates any remaining suspended solids and other contaminants, not eliminated in earlier stages. The efficacy is determined by the quality of the treated water. The primary goal of disinfection is to lower the number of germs in the effluent, which is disposed of in the natural environment. To eradicate hazardous substances in wastewater, disinfection methods use ozone, chlorine, and ultraviolet (UV) radiation. Nitrogen, phosphorus, and other harmful pollutants are removed during this stage.

Choosing the best ETP Manufacturer for hospitals

Netsol Water is a prominent producer of hospital effluent treatment plants in Delhi - NCR, India. We also provide hospital biological waste treatment, and manufacture other varieties of wastewater as well as water treatment plants.