Effluent Treatment Plant Manufacturer

Netsol Water builds reliable effluent treatment plants for many industries across India. As a leading Effluent Treatment Plant Manufacturer, Industrial ETP Manufacturer and provider of industrial wastewater treatment systems, The company has strong experience in design, fabrication and commissioning. Netsol Water delivers turnkey ETP solutions from initial survey to final handover. The plants meet CPCB and SPCB standards for discharge and reuse. Netsol Water serves clients across all major industrial regions in India through a strong PAN India network that ensures quick support and timely project execution.The team focuses on long term performance and easy operation. Netsol Water provides training and documentation with every installation.

What Is an Effluent Treatment Plant?

An effluent treatment plant is a plant that treats industrial wastewater to safe levels for discharge or reuse. The plant removes solids, oil, grease, organic matter and toxic components. Regulators require appropriate treatment before releasing water to the environment. Industries must treat effluent to protect public health and local water bodies. An effective ETP reduces pollutants and helps companies meet compliance. The design depends on the industry process flow and the specific contaminants present.

Importance of Effluent Treatment Plants

Effluent Treatment Plants, commonly known as ETPs, are advanced systems designed to treat industrial wastewater, chemical contamination and sewage to ensure that the treated water can be safely discharged into the environment or reused. These plants play a vital role in mitigating the harmful impact of industrial processes on water bodies and the environment. Netsol Water is one of the top-leading effluent treatment plant manufacturer, the brand trusted in the field of wastewater management is a leading wastewater treatment company manufacturing ace machines like Effluent Treatment Plant, Sewage Treatment Plant that not only treats your wastewater but also saves money, saves earth resources.

Industries generate vast amounts of wastewater, laden with pollutants and chemicals, which, if left untreated, can cause irreparable harm to our ecosystems. This is where Effluent Treatment Plants (ETPs) come into play as crucial environmental saviors. ETP Plant treats chemicals coming out from Hospitals, Manufacturing Industries, etc. The treated wastewater can further be used in Horticulture, Construction as it functions similarly to the Sewage Treatment Plant.

Netsol Water as Leading Effluent Treatment Plant Manufacturer

Netsol Water stands as a leading effluent treatment plant manufacturer in India. The company is widely recognized as a best effluent treatment plant manufacturer in India and trusted ETP system supplier. The company uses practical engineering with precise fabrication. Netsol Water manufactures equipment at its own facilities to ensure quality and timely delivery. The team customizes each plant to match the industry process flow and effluent profile. Netsol Water stands as a leading industrial ETP manufacturer. Netsol Water uses robust materials and proven components. The firm supports clients with installation, operation and maintenance services. Netsol Water aims to reduce the environmental footprint of each plant while lowering total cost of ownership.

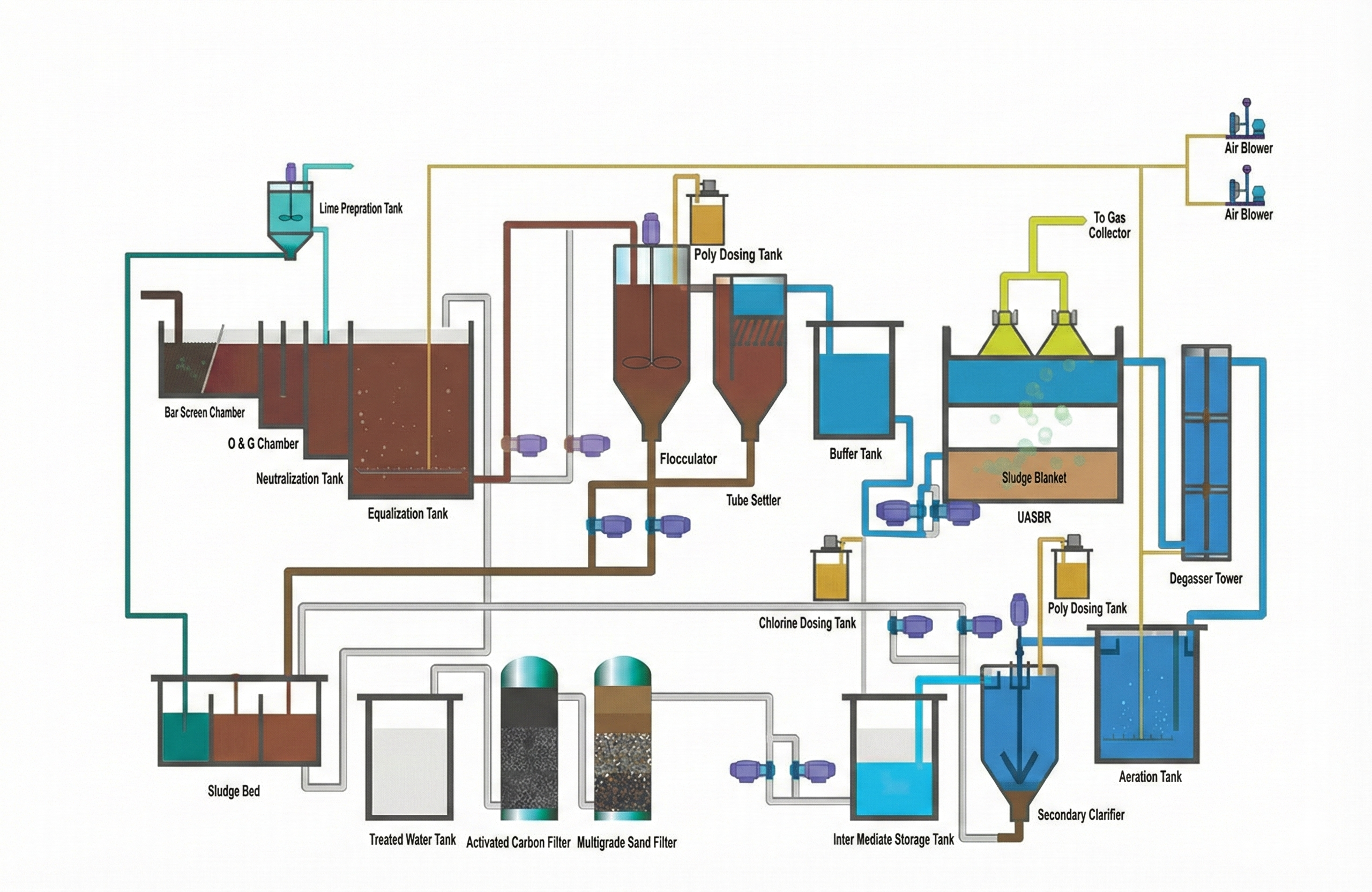

How does an Effluent Treatment Plant work?

Raw effluent enters into the primary filtration chamber where solid waste particles are removed with the help of fine and coarse screens. The next step is the oil & grease trap where the skimmer is used to separate oil from the raw effluent. The raw water then enters into the equalization tank where effluents are cooled down (oxidation) with the help of a blower and maintain equal temperature.

The next step is the neutralization tank, where effluents are mixed with alkali base or acid to neutralize and maintain the ph level and is measured using ph meter. The raw water then moves toward the coagulation tank where coagulant is added such as alum to further remove the layer from the effluent or raw water.

After this process, raw water enters into a settling tank and effluent gets separated from the water and settles down at a lower level of the tank. The effluent removed acts as sludge and can be used as manure in the agriculture industry vice-versa. The last and final stage is the filter stage where filtration is done under the pressure and we get the treated wastewater.

Netsol Water, The Effluent Treatment Plant Supplier in India served 500 plus customers and still serving them. #SaveWater

Types of Effluent Treatment Plants We Manufacture

1: Primary Treatment Systems

Primary treatment focuses on removing suspended solids, oil and large particles from wastewater. Netsol Water designs equalization tanks to balance flow and stabilise the influent. The company provides neutralization tanks to correct pH and prepare water for biological stages. Oil and grease traps protect downstream units from fouling. Netsol Water sizes tanks and channels to suit each plant flow and loading. The firm uses simple mechanical systems that require low maintenance. These units create stable conditions for the next treatment steps and support the performance of an Industrial effluent treatment plant.

2: Secondary Biological Treatment

Biological treatment reduces dissolved and biodegradable organic matter. Netsol Water offers multiple proven biological systems. The activated sludge process uses aeration and biomass settling to remove organics. Moving bed biofilm reactors use media carrier technology to boost biological capacity in limited space. Sequencing batch reactors provide flexible batch treatment for varying loads. Membrane bioreactors combine biological treatment with membrane separation for better effluent quality. Netsol Water selects the biological route that suits the pollution load and space constraints. The design ensures stable operation and easy sludge managementwithin an Industrial effluent treatment plant..

3: Tertiary and Advanced Treatment

Tertiary treatment polishes effluent to meet strict discharge or reuse targets. Netsol Water supplies pressure sand filters and activated carbon filters for solids and organic removal. Ultrafiltration and reverse osmosis remove fine particulates and dissolved salts. Chemical dosing systems handle coagulation flocculation and disinfection. The company integrates these units to achieve the required quality for industrial reuse or zero discharge steps. Netsol Water optimizes these units for low consumable use and easy cleaning.

4: Zero Liquid Discharge Systems

Zero liquid discharge systems aim to eliminate liquid waste from the plant. Netsol Water fabricates evaporators that concentrate effluent and convert water to vapor. The company supplies anti fouling thermal devices to enhance evaporation efficiency. The recovered water goes through further polishing for reuse. Netsol Water can deliver a complete water recovery solution that produces solids for safe disposal. The ZLD systems reduce water demand and cut discharge costs. Netsol Water is a leading ZLD system manufacturer.

Effluent Treatment Plant Manufacturing Process

1: Wastewater Analysis and Feasibility

Netsol Water begins every project with a detailed wastewater analysis and feasibility study. The lab tests identify pH, COD, BOD, TDS and specific contaminants. The team measures flow patterns and seasonal variations. The analysis guides process selection and cost estimates and forms the first step of the ETP manufacturing process.

2: Process and Hydraulic Design

The engineering team converts lab results into a process flow diagram and hydraulic design. Netsol Water sizes tanks clarifiers and pipes to avoid short circuits and solids buildup. The design also includes access for maintenance and safe operation. This stage builds the foundation of accurate ETP plant design.

3: Equipment Fabrication

Netsol Water fabricates tanks vessels and structural parts at its manufacturing facility. The company uses suitable materials such as FRP and steel depending on the chemistry and site conditions. Each component undergoes quality checks before dispatch. Netsol Water fits components for easy installation and alignment to support a smooth ETP manufacturing process.

4: Installation and Commissioning

The site team handles civil interface mechanical erection and piping. Commissioning starts with dry checks then with water trials. Netsol Water calibrates instruments and tests control logic during commissioning. The firm runs trial operation until performance targets meet client requirements. These steps complete the practical phase of ETP plant design and implementation.

5: Testing and Performance Guarantee

Netsol Water conducts performance tests to verify removal efficiencies and compliance with standards. The company provides a performance guarantee based on agreed parameters. The firm documents results and hands over a full operation manual once the ETP manufacturing process reaches completion.

6: Training and Documentation

Netsol Water trains plant operators and maintenance staff at site. The company supplies detailed drawings spare parts lists and standard operating procedures. This support helps clients run the plant with confidence and backs the long term success of the ETP plant design.

Effluent Treatment Plant Design Challenges and Engineering Solutions

1: Fluctuating Wastewater Characteristics

Many industries show large swings in flow and pollutant load during production cycles. Netsol Water uses equalization and buffer systems to stabilise influent. The company designs control strategies that adapt aeration and dosing to changing load. This approach prevents process upset and maintains effluent quality.

2: High COD and High TDS Challenges

High chemical oxygen demand and high dissolved salts pose treatment difficulties. Netsol Water combines robust biological treatment with advanced tertiary units. For very high TDS the firm recommends partial recovery and ZLD options. The design minimizes chemical use and prevents membrane fouling.

3: Space Limitations

Urban and retrofit sites often lack space for large treatment trains. Netsol Water offers compact solutions like MBBR and MBR that reduce footprint. The company uses vertical arrangements and modular skids for tight sites. These solutions accelerate installation and save civil costs.

4: Shock Loads and Toxic Influent

Sudden toxic discharges can harm biological systems. Netsol Water installs equalization and neutralization steps to buffer shocks. The firm also adds bypass and pretreatment for highly toxic streams. Instrumentation provides early warning to protect the biological units.

5: Sludge Bulking and Foaming

Sludge bulking and foaming can reduce clarification and increase solids carryover. Netsol Water tunes aeration and microbial balance to prevent these issues. The company also offers mechanical clarifiers and sludge handling systems to maintain solids control.

Netsol Water applies smart engineering and adaptive control to solve these common problems. The company focuses on simple reliable fixes that minimise downtime and operating cost.

Wastewater Treatability Study and Pilot Testing Before ETP Design

Netsol Water values lab based treatability studies and pilot testing for accurate design. The studies confirm which biological and physical processes will work. Pilot units simulate real conditions and show expected performance. This approach reduces technical risk and avoids overdesign. Pilot testing helps choose the most economical technology for long term operation. The data from trials also support a realistic lifecycle cost estimate. Netsol Water uses these studies to optimize chemical dosing aeration and sludge handling strategies.

Life Cycle Cost Analysis of Effluent Treatment Plants

Buyers must weigh initial investment against long term operating cost. Netsol Water performs life cycle cost analysis to show total cost of ownership. The study compares capital cost and expected expenses for power chemicals and sludge management. Netsol Water evaluates options that reduce energy and chemical demand. The company recommends efficient blowers and proper automation to cut power consumption. Netsol Water also considers OPEX impact of membrane replacement and spare parts. Clients get clear projections that support sound investment choices.

Automation PLC and Instrumentation in Effluent Treatment Plants

Automation improves reliability and reduces manual errors in ETP operation. Netsol Water integrates PLC and SCADA for real time control and data logging. The systems include online pH, COD and TDS monitoring to track performance. Remote access enables supervisors to review alarms and trends from any location. Netsol Water programs control loops for aeration dosing and sludge recirculation to stabilise treatment. The company also configures automatic reports and alert systems to meet compliance reporting needs. Automation lowers manpower needs and raises plant uptime.

Energy Optimization and Cost Reduction Strategies in Industrial ETPs

Energy efficient design lowers operating cost and improves sustainability. Netsol Water selects high efficiency blowers and motor systems. The company uses variable frequency drives to match energy use with process demand. Optimised aeration control reduces wasted oxygen and power. Netsol Water favours gravity based layouts that reduce pumping needs. The firm also studies heat recovery and process integration where applicable. These measures trim energy bills and reduce the carbon footprint of the treatment plant.

Industries We Serve with ETP Solutions

Netsol Water works with pharmaceutical manufacturers that need precise effluent control. The company serves chemical plants that generate complex waste streams. Textile and dyeing units receive specialised treatment for color removal and salt reduction. Food and beverage processors rely on Netsol Water for organic load handling. Dairy plants gain low maintenance systems that handle fats and solids. Distilleries and breweries use personalized designs for high COD streams. Automotive facilities depend on robust systems for oils and solvents. Electroplating shops require metal removal and strict pH control. Paper and pulp mills receive scalable solutions for fiber and chemical residues. Netsol Water adapts designs to each industry need and to local regulations.The firm provides ETP for textile industry solutions and tailored ETP for pharmaceutical industry services.

Why Choose Netsol Water as Your ETP Manufacturer?

Netsol Water offers customised designs that match the industry process and the site constraints. The company delivers energy efficient solutions that reduce operating cost. Netsol Water focuses on low maintenance operation to keep downtime minimal. The plants meet CPCB and SPCB norms for safe discharge and reuse. Netsol Water provides annual maintenance contracts and rapid support services. The firm documents every project and provides training for plant staff. Netsol Water shows proven installations across India and shares performance records on request. This makes Netsol Water a Trusted ETP supplier and a Best effluent treatment plant manufacturer for long term partnerships.

Effluent Treatment Plant Cost and Design Factors

Several factors influence the cost of an effluent treatment plant. The primary factor is the flow rate expressed in KLD or MLD. The industry type affects technology needs and pretreatment steps. The pollution load drives the size of biological and tertiary units. Technology selection determines equipment cost and operating expense. The level of automation influences both capital and recurring costs. Netsol Water prepares detailed quotes that explain how each factor affects price. The company helps clients choose trade offs that optimise both CAPEX and OPEX.For clear budgeting clients receive an estimate that covers Effluent treatment plant cost and an indicative ETP price in India.

Benefits of Installing an Effluent Treatment Plant

Installing an ETP keeps the plant compliant with environmental rules and reduces the risk of penalties. Proper treatment enables water reuse within the process thus reducing freshwater demand. ETPs cut pollution load and protect local water bodies and communities. Efficient systems lower long term operating cost compared to ad hoc disposal methods. Installing a reliable plant supports sustainable operations and improves the corporate image.Netsol Water helps clients realise the Benefits of effluent treatment plant investment through engineered systems that perform reliably.

Case Studies and Projects Executed

Netsol Water executed a 10 KLD ETP for Biryani By Kilo at Gurgaon unit. The client faced high color and variable flow. Netsol Water installed primary equalization followed by MBBR and ultrafiltration. The solution reduced color and COD to meet discharge standards. The plant achieved steady operation with low chemical use.

For a pharmaceutical unit Netsol Water delivered a 20 KLD plant that handled variable toxic loads. The design included targeted neutralization and sequencing batch reactor units. Pilot tests ensured correct technology selection. The outcome produced compliant effluent and reduced sludge production.

Netsol Water installed a ZLD system for Paramount Home Collections with 50 KLD flow. The firm combined evaporation with RO polishing to recover process water. The client recovered a large portion of the feed water and reduced discharge costs. Each project included training and a performance guarantee. Netsol Water documents results and supports clients during the critical initial months of operation.These Industrial ETP projects demonstrate the Netsol Water ability to deliver reliable outcomes.

Compact Effluent Treatment Plant Manufacturers

The wastewater can easily be treated with the help of Compact Effluent Treatment Plant which when placed anywhere gives exponential growth in terms of saving water and utilizing it further giving 100 percent return on investment. Compact Effluent Treatment Plant comes under different variants of capacity similar to Compact Sewage Treatment Plant, designed according to the parameters such as GA (General Arrangement ) view, type of effluent and the no of population.

Advantages of choosing Netsol's Effluent Treatment Plant Manufacturer

1. Saves water - By the help of ETP plant's, after wastewater treatment treated water can be reused or safely discharged into nature to be in process.

2. Low maintenance cost - ETP plant manufactured by Netsol Water comes up with low maintenance cost with high the high quality of equipment uses and with latest technology upgradation.

3. Low operation cost - Operation cost is lower than other machines available in the market, just because we used world class motors, pumps and other equipment with are energy certified by BIS and other internation agencies for low power consumption.

4. Effluent Sludge is of high quality - Treated sludge also can be utlized in organic farming and some other uses just making some necessary polishing over it.

5. Efficient Cleaning - Our machines are very much capable of treating any kind of effluent from industries, this is possible because we are customize effluent treatment plant manufacturer and our machines can be designed as per user imput parametere to achieve high standard output.

6. High ROI - Our ETP's can provide the high return on treating the wastewater which will cost you around .03 to .05 paisa (INR).

7. Pollution Control - ETPs significantly reduce the pollution load in wastewater, making it safe for discharge.

8. Sustainable Resource Management - These plants promote the sustainable use of water resources by recycling treated water for various industrial purposes.

9. Cost-Efficiency - Implementing ETPs can lead to cost savings in terms of reduced water consumption and regulatory compliance.

10. Environmental Responsibility - ETPs showcase a company's commitment to environmental responsibility, improving its public image.

The Significance of Effluent Treatment Plants

1. Environmental Conservation: ETPs are champions of environmental preservation. They are essential in reducing the contamination of natural water sources, which is crucial for the survival of aquatic life and the well-being of ecosystems.

2. Legal Compliance: Many state in India, and other countries have stringent regulations in place that mandate the treatment of industrial effluents before disposal. ETPs help industries meet these regulatory requirements, avoiding hefty fines and penalties.

3. Resource Reclamation: ETPs facilitate the recovery of valuable resources from wastewater, including water itself, which can be recycled for industrial processes, thus conserving this precious resource.

4. Community Health: By treating effluents, ETPs protect nearby communities from the adverse health effects of exposure to contaminated water.

Applications of Effluent Treatment Plant

1. Effluent Treatment Plant used in Pharmaceutical Industry: Pharma industries generates a substantial amount of wastewater and chemical byproducts during its manufacturing processes. To address this environmental challenge, pharmaceutical companies have turned to Compact Effluent Treatment Plants (CETPs), which are emerging as a game-changer in sustainable pharmaceutical production.

2. Effluent Treatment Plant used in Oil & Mining Industry: ETPs promote resource efficiency by reclaiming and recycling water, reducing overall water consumption in resource-intensive industries like oil and mining.

3. Effluent Treatment Plant used in Paper Mill Industry: Our advanced system can recover valuable materials or chemicals as well as water from wastewater, providing economic benefits.

4. Effluent Treatment Plant used in Chemical Dye Industry: ETP plant in dye industry help mitigate pollution, protect ecosystems, and ensure the responsible management of water resources.

5. Effluent Treatment Plant used in Leather Industry: Netsol Water effluent treatment plants (ETPs) supplier, are essential in the leather industry, managing wastewater laden with dyes, chemicals, and organic matter. These plants employ processes like screening, chemical treatment, and biological degradation to purify effluents. ETPs ensure compliance with environmental regulations, prevent water pollution, and protect ecosystems.

6. Effluent Treatment Plant used in Automobile Industry: For treating wastewater contaminated with oils, heavy metals, and chemicals from automobile industry ETP palnt paly important role by ensuring compliance with environmental regulations, reduce water pollution, and support responsible resource management.

Frequently Asked Questions

Is an effluent treatment plant mandatory in India?

Regulatory agencies mandate treatment for many industrial discharges. The exact requirement depends on the industry type and the local pollution control board. Most chemical pharmaceutical textile and food processing units must install an ETP. Netsol Water helps clients understand the applicable rules and the standards that apply.

How long does ETP installation take?

The schedule depends on plant size scope and civil work. A small prefabricated plant can be installed and commissioned in a few weeks. Larger systems that require civil structures take several months. Netsol Water provides a clear timeline after site survey and design approval.

What is ETP maintenance cost?

Maintenance cost varies with technology and the pollution load. Biological systems need routine checks and occasional media replacement. RO and membrane units require periodic cleaning and replacement. Netsol Water offers service agreements that cover routine maintenance and spare parts. A proper lifecycle cost analysis helps clients budget for these expenses.

Which industry requires ETP?

Industries that produce wastewater with organic load chemicals heavy metals or oil require ETPs. This includes pharmaceutical, chemical, textile, food, dairy,distillery, automotive, electroplating and paper mills. Netsol Water modifies systems to match each industry need.

Can Netsol Water offer pilot testing?

Yes Netsol Water performs lab based treatability studies and pilot trials. These tests confirm the chosen process and reduce technical risk. Pilot testing also optimizes dosing aeration and expected operating cost.

Does Netsol Water provide AMC and support?

Netsol Water provides annual maintenance contracts and site support. The company offers remote monitoring and on site visits as needed. Training forms part of the handover package.

What is the expected life of an ETP?

With proper maintenance and periodic replacement of wear items the mechanical life of the plant can be many years. Parts such as membranes have defined lifetimes and Netsol Water advises on replacement schedules to keep performance steady.

How to choose between ZLD and discharge?

The decision depends on regulatory requirements reuse goals and cost. ZLD reduces discharge but increases capital and energy cost. Netsol Water helps clients compare options using a lifecycle cost study to find the right balance.

Netsol Water not just only effluent treatment plant manfacturer but also offers Industrial RO Plant of different capacities which saves every drop of water by removing the contaminants, dust, TDS (Total Dissolved Solids) and makes it desirably perfect for human consumption.

Contact the Best Effluent Treatment Plant Manufacturer

For a free consultation and site visit contact Netsol Water. The team will review your wastewater profile and provide a recommended solution with cost estimates. Call +91-9650608473 or email enquiry@netsolwater.com to start the conversation. Netsol Water welcomes technical queries and provides a detailed proposal after a site survey. Netsol Water builds effluent treatment plants that meet regulatory standards and deliver reliable performance. Clients gain lower operating cost better compliance and improved water recovery. Netsol Water stands ready to design, fabricate, install and commission the right ETP for your industry. Contact the team today for a free consultation and clear next steps.