What is completely mixed reactor process with sludge recycle?

The microbiological process is used in activated sludge plants to degrade organic pollutants in wastewater. The method does not necessitate the use of chemicals (maybe in insignificant amount). When compared to the chemical method of treatment, the operational cost is low. The biodegradation process, on the other hand, is slow, and the plant necessitates a large footprint of facilities.

In recent years, highly polluting industries have thrived in densely populated countries with poor economies, low-wage labor, and liberal environmental laws. As a result, while the biological method of wastewater treatment appears to be appropriate in those countries at times due to favorable atmospheric conditions, it is rarely chosen because it requires a large amount of space. The biological treatment method is environmentally friendly and in high demand.

The goal of this work is to

1.Develop a method for concurrent design of a reactor and a settling tank that comprises an activated sludge plant for an assigned performance level.

2.To create an analytical and graphical method for determining the range of recycle ratio and activated sludge concentration required to achieve a specific treatment level.

3.To devise a design method that ensures the plant's footprint is as small as possible.

4.Determine the operating conditions of an already operational plant in the event that the input parameters (influent flow rate and substrate concentration) differ from those assumed in design.

The process of completely mixed reactor

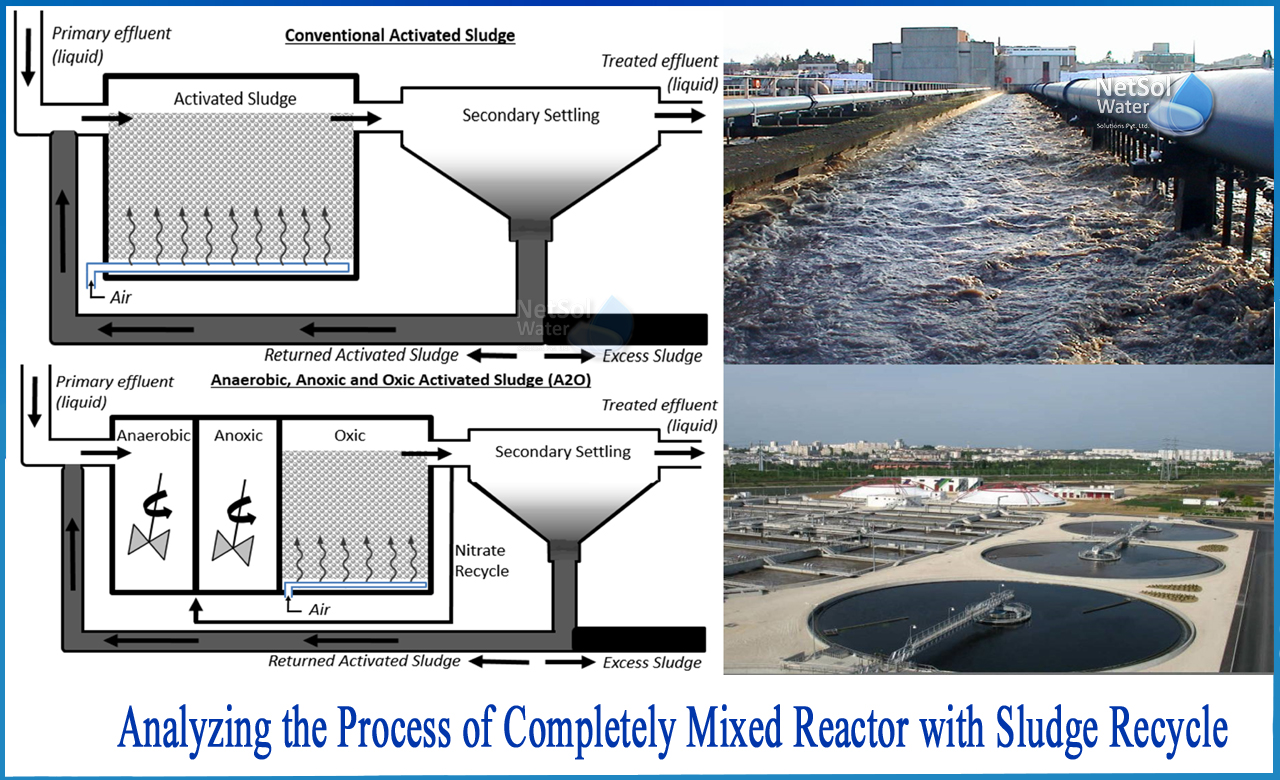

The activated sludge plant is thought to be made up of two units:

An activated sludge reactor and a settling tank.

The reactor's design parameter is volume, and the settling tank's is area. The design parameter of both units has been reduced to area, assuming a fixed height for the activated sludge reactor. As a result, the minimum total area (footprint) of the units is accepted as the optimization criterion.

The “Monod equation” is assumed to fully describe the growth kinetics of microorganisms, and the settling characteristics of the sludge.

The total area of the plant is determined by three variables in the design of the interacting reactor-settler system-

The activated sludge concentration ‘X’ in the reactor, the sludge recycle ratio, and the sludge waste ratio.

To reduce the number of variables, the value is held constant at 0.01. Contrary to popular belief, an increase in results leads to an increase in the biodegradation rate and a decrease in the overall space required for the plant. It is discovered that an increase in results in a monotonous increase in the total area of the plant.

When the feed parameters differ from those assumed in the plant's design, the sludge recycle ratio appears to be the only controllable parameter to maintain the desired level of treatment in the plant when the sludge waste ratio is kept constant. A procedure for simultaneous design of a reactor and settling tank, ensuring minimum area (footprint) for an activated sludge plant, has been developed, as has a methodology for recalculating the operating sludge recycled ratio when influent parameters differ from those in design.

Conclusion

The inclusion of newer and newer elements in the rate equations of the processes in the reactor increases the complexity, as does the precision of the predictions.

What can Netsol Water offer?

Netsol Water offers a comprehensive range of water and wastewater treatment technologies and services to meet the demands of a variety of industries, and our skilled staff can make suggestions on the best solution. This might be as simple as optimizing current equipment and methods to achieve the desired performance or including a new phase into the treatment process.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.