Dead-end filtration or cross-flow filtration are the two primary types of filtration techniques, which may be used in industrial applications. To achieve higher levels of filtration, cross-flow microfiltration is frequently employed in conjunction with reverse osmosis and ultrafiltration.

Knowing how different filtration techniques differ can assist choose the right system for a specific application. Let's examine the distinction between cross-flow filtration and dead-end filtration.

Which type of filtering should we use when it comes to filters?

Dead-end filtering is typically employed when the solid content of the raw water, is less than 0.5% in order to conserve energy and water resources. Cross-flow filtration is typically employed to ensure filtering effectiveness and extend service life, when the solid content of the raw water is more than 0.5%.

Difference between Cross Flow Filtration and Dead End Filtration

· Direction of Liquid Flow

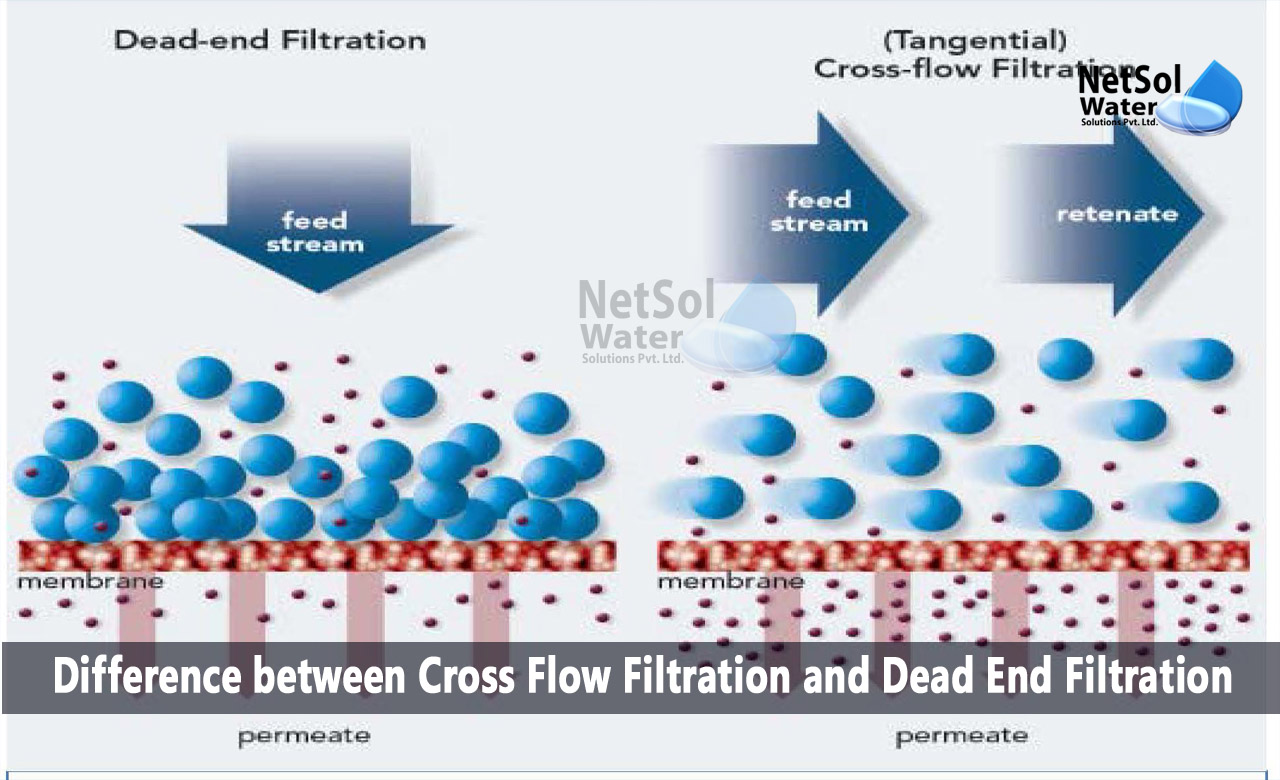

The liquid flow direction and the filtering direction are the same for dead-end filtration. Raw water contains particles larger than the filter media's pore size, which are trapped on its surface, while liquid and particles smaller than the filter media's pore size pass through it.

The liquid in the raw water and particles that is smaller than the pore size of the filter media, pass through the filter media during cross-flow filtration. Particles that are larger than the pore size of the filter media are separated into two groups: those that are trapped on the surface of the medium, and those that are washed away by the water and released.

· Flow changes in the liquid

Since, the trapped particles are not released when the dead-end filtration method is used, the filter cake gradually builds up on the filter media's surface. The filter cake gets thicker and thicker with time, eventually fully obstructing the filter medium and decreasing the liquid flow.

In comparison to dead-end filtration, the filter cake that forms on the surface of the filter media is thinner when cross-flow filtration is utilized, because some of the trapped particles will be rinsed away by the water flow. This causes the liquid flow rate to decrease more gradually.

· Effort on the Filter Media

The filter cake on the surface of the filter medium will thicken and thicken during the course of the dead-end filtration process, and the pressure difference will grow and grow. Additionally, more pressure must be applied when backwashing.

Cross-flow filtration produces a thinner filter cake than dead-end filtration, resulting in a smaller pressure difference and backwashing pressure.

· Effect on membrane surface

The membrane surface is attacked by dead end filtering systems at a right angle, allowing for increased flux rates throughout the entire membrane. However, the membrane surface experiences greater stress as a result of this.

Due to a concentrate-side bleed, the flow stream in cross-flow filtration systems is parallel to the membrane's surface, reducing stress on the membrane.

· Cake formation

When particulates are trapped by a membrane in a dead-end filtration system, they take the shape of a cake and accumulate over time. This build-up, often referred to as filter cake, is thicker in dead-end filtration systems than in cross-flow filtration, where the cake is automatically washed away by the tangential flow.

· Feed flow velocity

In dead-end systems, the particulate matter velocity decreases to zero from its feed value, which is correlated with the formation of thicker filter cakes. The minimally reduced particle velocity caused by the regulated bleed in cross-flow systems, puts less strain on the membrane and improves overall performance.

· Water use and recovery

Since, the flow liquid can only pass through the membrane, dead-end filtration systems have a higher apparent recovery. These technologies also prevent any leaks or bleeds, resulting in a 95% recovery rate. Due to the 2-9% bleed, the apparent recovery with cross-flow filtration is not as high.

Are you still not sure about the differences! Or, do you want a water treatment plant for your water purification!

Netsol Water is a top producer of industrial and commercial water treatment plants and wastewater treatment plants. We provide different products to help you improve your water quality.

All kinds of chemical, physical, and biological impurities can be effectively eliminated, by our water treatment systems. For further information or to make a product purchase, contact us at +91-9650608473 or drop a mail at enquiry@netsolwater.com