How is RO process linked with electro membrane separation process?

Reverse osmosis is a water treatment technology in which enough pressure is applied to feedwater to drive it through a semipermeable membrane, separating water molecules from other constituents. The feedwater is separated into two effluent streams by reverse osmosis (RO), the desired permeate and a higher salinity concentrate (reject) stream.

The type of ions, ionic charge, molecular weight, molecular structure, and molecule hydrophobicity all play a role in membrane rejection characteristics.

Industrial activities and the generation of potable (drinking) water can both benefit from reverse osmosis. Surface, groundwater, wastewater, industrial process, and ocean sources are all possible sources of feedwater.

Processes involving electro-membrane separation

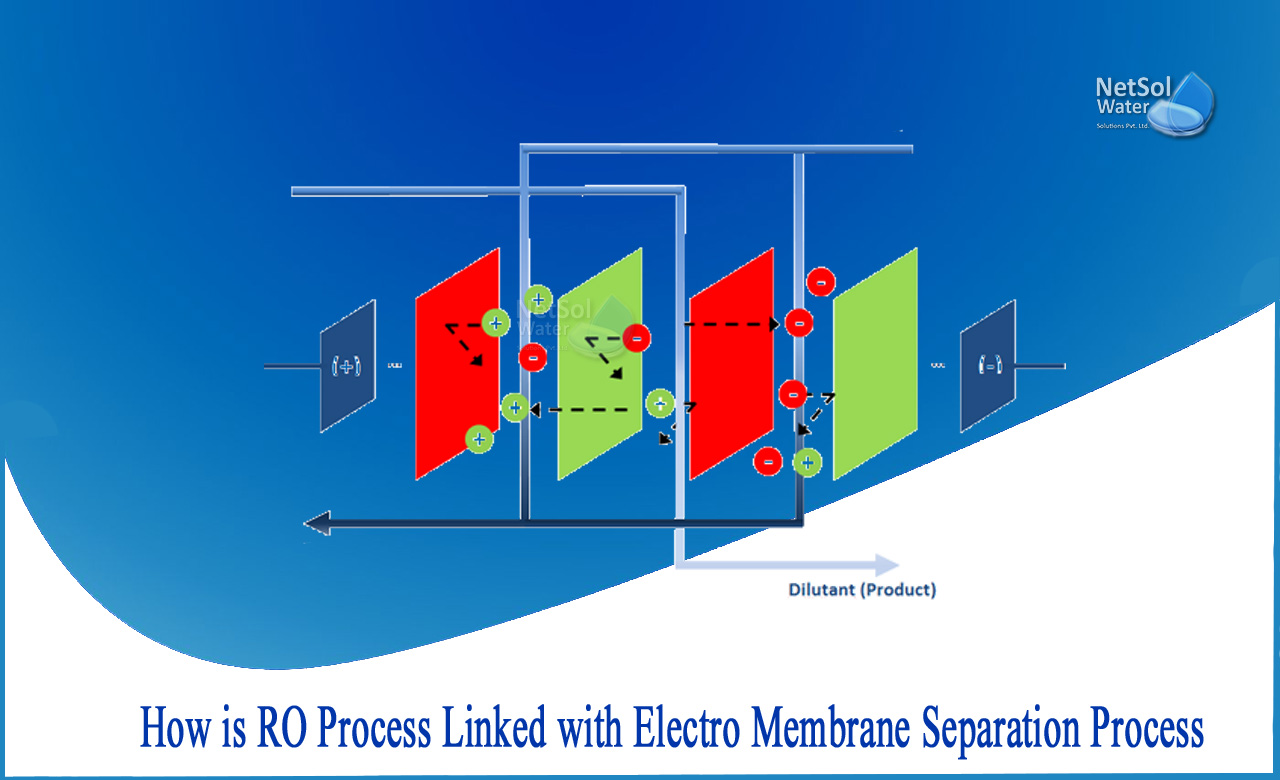

The technologies that use the electric potential gradient as the driving mechanism for ion transport are known as electro-membrane processes. They are a growing collection of separation methods for removing charged components from solutions, such as making potable water from brackish water.

The following are the main electro-membrane processes:

1: Electro deionization (EDI);

2: Electrodialysis (ED);

3: Reversal of electrodialysis (EDR);

4: Bipolar membrane electrodialysis (EDBM);

5: Deionization through capacitive deionization (CDI);

Electromembrane processes have the following advantages-

1: High separation efficiency of compounds without phase transitions.

2: Easy to automate and continue, with minimal space requirements.

3: When compared to traditional techniques, it uses less energy.

4: The ability to produce waste-free, closed technical junctions or complete technologies.

How is RO process linked with electro membrane separation process?

Membranes with substance selectivity are known as semipermeable membranes; in general, perfect semipermeable membranes allow just the solvent to pass through but not the solute.

In biotechnology, membrane processes are critical for downstream processing. This is due to their selectivity and gentle operating conditions, which allows for the extraction of target compounds without overheating or chemical agents causing damage. Electrodialysis is particularly significant for the removal and extraction of electrically charged products, such as anions of organic acids, certain antibiotics, and so on, in addition to the most widely used membrane procedures like reverse osmosis.The electrodialysis procedure can be carried out in batch or continuously.

In electro-crossflow filtration, on the other hand, two main driving forces, the trans-membrane pressure, and the electric potential, guide the transport of target solutes across the membrane. This combination opens up a world of possibilities for biotechnology downstream processing that is more selective and efficient.

What do we offer?

Membrane separation has been widely employed in various fields as a new separation technology in combination with electro-membrane processes. It is one of the future water treatment development directions. It not only has a good treatment impact when used in wastewater treatment, but it can also be recycled and used to provide significant economic, social, and environmental advantages.

If you want to know more about how the RO process can be used in combination with various electro-membrane separation processes, then you are at the right place!

You can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water treatment plants and Wastewater treatment plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.