What is Silt density index in wastewater treatment?

The silt density index (SDI) quantifies the number of suspended and colloidal particles in water. It is widely utilized in the selection and design of water treatment equipment, particularly membrane filtration systems, because it provides information on the device's fouling potential. SDI is a simple and effective approach for determining the fouling potential of NF and RO membranes, in pilot and large-scale treatment facilities.

What does SDI Measure?

The SDI measures the fouling ability of suspended particles. Because the size and shape of the matter vary, measuring the quantity of that matter is impossible.

Turbidity measures the number of suspended particles. They are not usually the same and have no clear connection. In reality, however, these membranes demonstrate very little fouling, anytime the feed water seems to have a turbidity of less than 1 NTU. When the feeding SDI is less than 5, the membranes display very less fouling.

The SDI test is intended to predict particle fouling on the membrane surface, and thereby avoid it. It is also known as the Fouling Index (FI).

Is SDI measurement helpful?

The SDI can assist you with determining the amount of particulate matter in your water. The SDI is useful for determining the efficiency of different particulate matter removal processes, like as filtering or clarifying. Because the SDI fluctuates with water temperature, data obtained at different temperatures may not even be comparable. The required SDI varies according to the membrane filter manufacturer. As a result, SDI values obtained with filters manufactured by various membrane manufacturers are not comparable.

Water specialists utilize SDI measurements on a regular basis, to ensure that the pretreatment filter solution is supplying high-quality, appropriate liquid to the reverse osmosis system.

Silt Density Index testing principle

At a pressure of 30 psi, water is forced through a 0.45-micron absolute filter membrane, with a tiny diameter of 47 mm. The time required to transit 500 MLS at the end of 5, 10, and 15 minutes is recorded, and used to calculate the SDI value without units.

Calculation of Silt Density Index

Formula for calculation of SDI

SDI=(1-ti/tf)100/T

Here;

· T = total test time (in minutes).

· Ti = the starting time (in seconds) necessary to gather 500 ml of sample.

· Tf = time (in seconds) necessary to collect 500 ml of sample, after a flow of 15 minutes or less.

Effects of Silt on Effluent Treatment

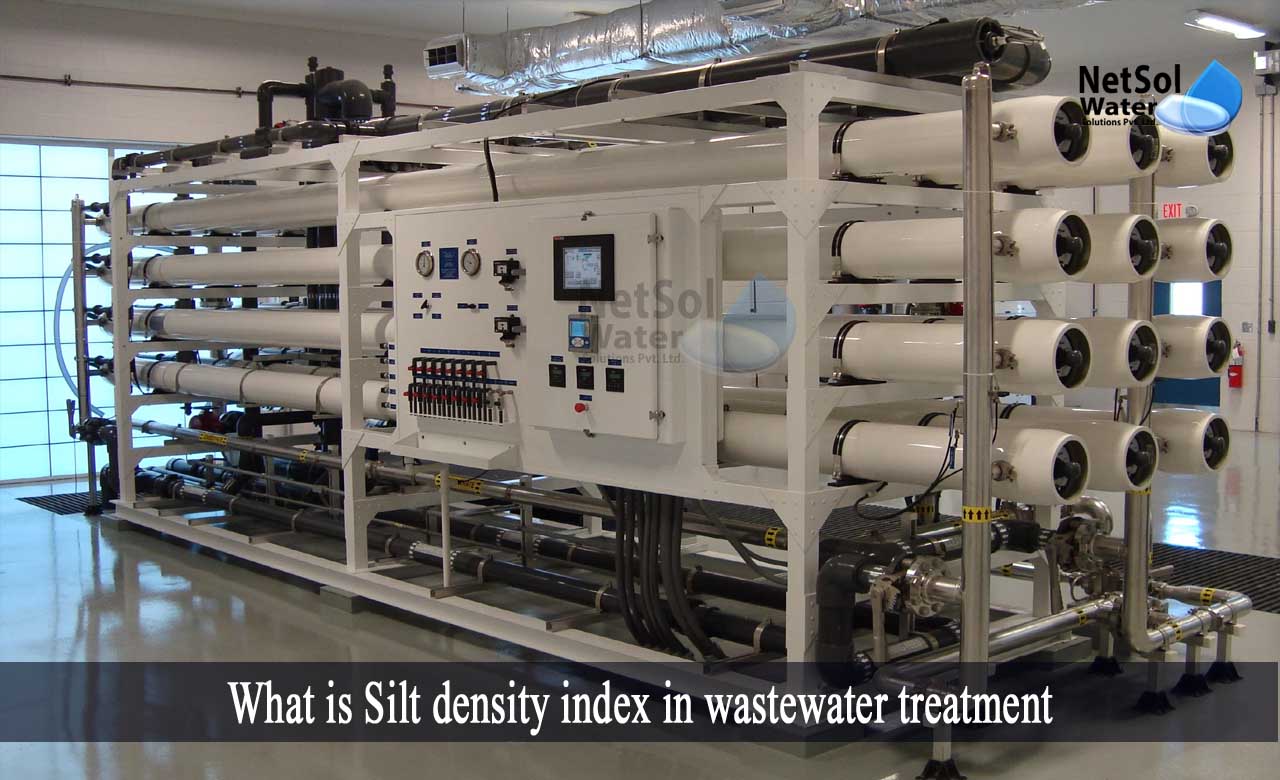

One of the most difficulties in reverse osmosis systems, is the presence of suspended particles in the feed solution. While most systems have some type of disinfection, it is small particles that cause Reverse Osmosis Membranes to clog. The silt density index helps in measuring the possibility of water fouling, in reverse osmosis plants.

Conclusion

Pre-treating the supply water to decrease fouling and washing on a regular basis, to eliminate any leftover fouling are both parts of fouling prevention. The initial modules within the plant are generally the ones that suffer the most from fouling, caused by particles (silt), bacteria, and organics. Despite the fact that higher concentrated feeding solutions cause more scaling, the final modules in the plant are affected,since they get some of the saturated feed water.

How can we assist?

Membrane fouling is the primary cause of permeate flow deterioration, and product quality degradation in reverse osmosis (RO) facilities. Hence, fouling control is a crucial priority in RO systems. To maintain SDI in feed waters, our engineers guide operators to check water quality regularly, so that problem of membrane fouling in the treatment plants can be eliminated.

Netsol Water also provides the best and most reliable water and wastewater treatment solutions, including all membrane technologies, effluent treatment plants, sewage treatment plants, and much more.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.