What are the Applications of ETP, STP and WWTP?

WWTP or Wastewater treatment plant

Water that has been utilized in residential, agricultural, industrial, medicinal or transportation activities is referred to as wastewater.

Wastewater can be split into two categories:

Sewage Water: Wastewater from domestic activities such as toilets, showers, and even sinks is referred to as sewage water.

Industrial Wastewater: Industrial wastewater, on the other hand, is generated by manufacturing, industrial, and commercial activity and has a completely different chemical composition than sewage water.

How does it work?

The wastewater drains to the facility by gravity through the main sewer system as the first phase in the wastewater treatment plant.

The secondary treatment begins after the main treatment is completed. This stage is also known as the biological stage since it employs natural processes and microbes to eat contaminants such as biodegradable organic compounds, carbon, and phosphorus in the water. Sludge is formed when dead bacteria and organic wastes combine.

Inspection is the final phase in the wastewater treatment process. This inspection entails determining the degree of contamination in the treated water and ensuring that it meets the highest requirements before being discharged or reused for home or industrial reasons.

Applications of wastewater treatment plants

Most petroleum refineries, petrochemical plants, and chemical plants produce substantial amounts of wastewater, necessitating the installation of on-site wastewater treatment plants. Other industries, such as paper and pulp manufacturing, also generate a significant amount of wastewater.

Sewage Treatment Plant or STP

These facilities remove pollutants and sewage waste from homes and businesses, and they occasionally receive commercial wastewater as well. It can also accept rainfall and sewer waste.

STPs are important for inhabitants' health and safety because they clean wastewater using a variety of chemical, physical, and biological techniques before releasing it into the environment.

What is the mechanism behind it?

When wastewater arrives at a sewage treatment plant, it is filtered as part of the pre-treatment process. The wastewater here passes via screens and into settling basins, which can handle considerable amounts of material.

As previously said, it functions as a pre-therapy because it occurs before three more aggressive rounds of treatment: primary, secondary, and tertiary treatment.

Primary Treatment: The wastewater is pumped into the clarifiers during this step. In the settlement basins, the wastewater moves slowly. The design of these tanks causes settling, in which biological solid matter accumulates at the bottom of the tank and lighter matter floats to the top, making clean-up easier.

Secondary Treatment: Aerobic aeration is used in this therapy phase. Aerators, which have a system of pipes or tubes connecting to them, are found in aeration basins. They're constructed out of ceramic or rubber membranes with small openings allowing air to pass through.

Tertiary Treatment: Secondary and primary procedures are combined in tertiary treatment, which also includes mechanical and photochemical processes. This is a more advanced treatment that comes in handy when dealing with sanitary sewage that contains microorganism pollutants that need to be cleansed.

Applications of sewage treatment plants

The treatment plants found in major cities are an excellent example of STP. Households, commercial buildings, municipal wastewater, and so on.

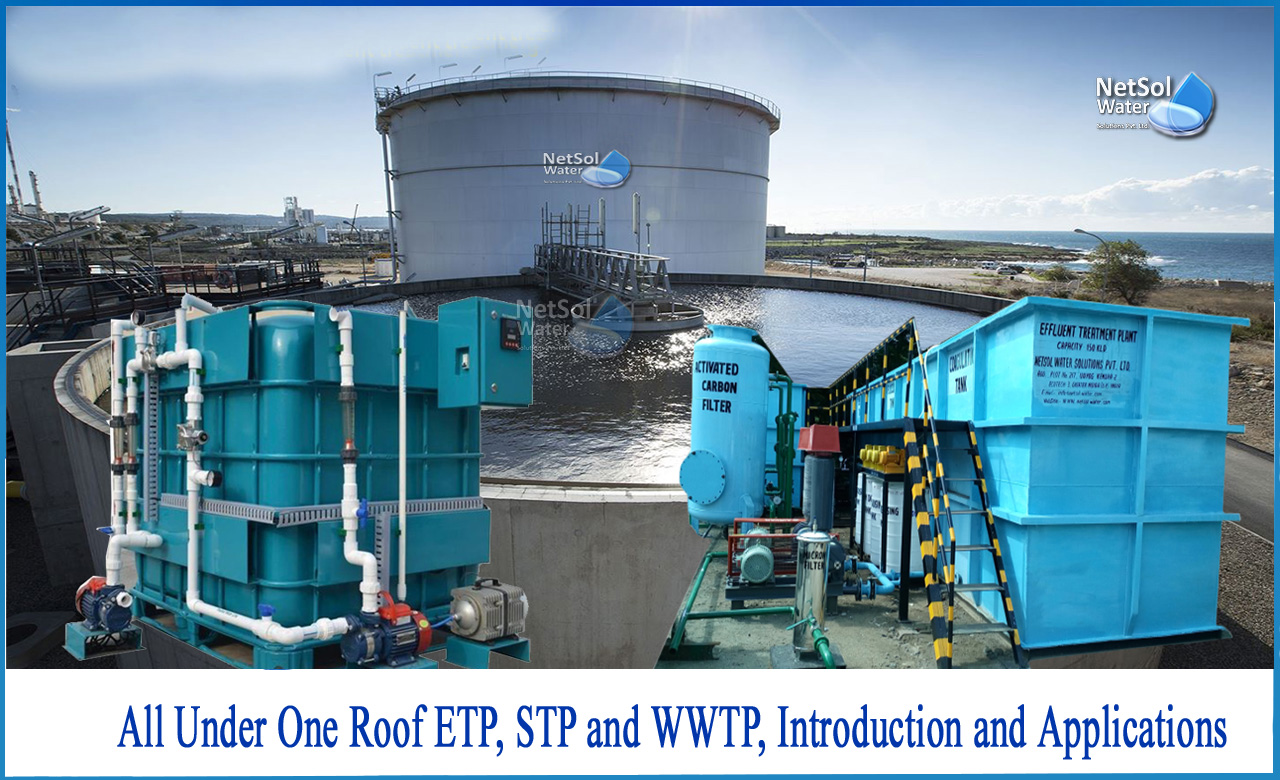

Effluent Treatment Plant or ETP

Sewage treatment plants treat sewage before it is discharged into the environment, whether it is for domestic or municipal use. Effluent water treatment plants, on the other hand, treat industrial effluent, or wastewater generated by the flow of byproducts from the industry.

How does it work?

Preliminary treatment: Here, physical processes such as screening, sedimentation, filtration, and clarifying are emphasised. The goal is to get rid of as much solid physical stuff as possible before sending the effluent to be treated further.

Primary Treatment: The removal of solid trash and organic debris is the first step in the treatment process. To break down any solid or chemical waste, chemicals are placed here. To manage pH levels, chemical coagulation, chemical precipitation, or the addition of sodium carbonate or hydrochloric acid are used.

Secondary treatment: Here, suspended particles and any biodegradable debris are removed using a combination of chemical and biological methods.

Tertiary treatment: To remove any final residues of solids or contaminants from the industrial effluent, tertiary treatment employs a combination of physical, chemical, and biological techniques.

Applications of Effluent Treatment Plants

ETPs are utilised in businesses where there is a lot of chemical contamination in the wastewater, like pharmaceutical manufacturing and chemical industries like textile and dye manufacture and many more.

Why Netsol?

If you are curious to know more about the water and wastewater treatment processes, you can contact Netsol Water Solutions where you can get a chance to talk to our experts and benefit from them. You can also have an expert advice about the treatment processing units, if you are interested in buying one.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.