WHAT IS PRODUCT WATER IN DIALYSIS?

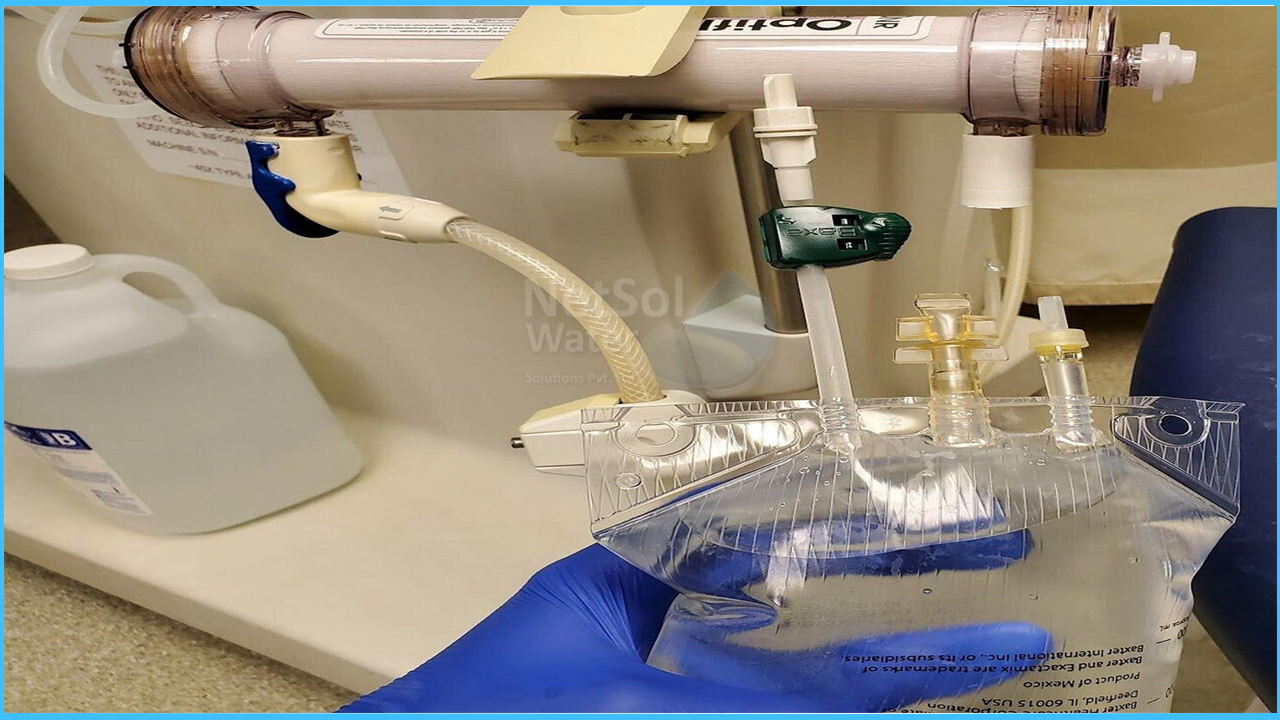

The reverse osmosis (RO) system employs a pump to force water through a semipermeable membrane or filter, which removes nearly all contaminants, including bacteria and viruses. A carbon filter, which soaks up the chemicals added by the water department, and a sediment filter, which traps large pieces of debris, are also components of a portable RO machine. There are two types of water produced by the RO machine: product water and reject water. The ultrapure water that enters the hemodialysis machine and is used to mix the dialysate for your dialysis treatment is referred to as product water. The reject water contains the bacteria that was removed from the water and is discarded after being flushed down the drain.

IMPORTANCE OF PRODUCT WATER IN DIALYSIS

The role that product water quality plays in improving outcomes for patients with end-stage renal disease has resulted in a tightening of microbiological and endotoxin levels, compliance with which necessitates a stringent quality control program.

Water for dialysis must be purer than drinking water for a variety of reasons, including:

- 1. Because the average volume of liquid consumed by a given individual is about 2 L/day, the exposure level is relatively low. Dialysis patients, on the other hand, have a high exposure because they come into direct contact with over 200 L of dialysis fluid per treatment, at least three times per week.

- 2. Drinking water allows the liquid to pass through the digestive tract and liver, where contaminants are inactivated or removed before being absorbed into the bloodstream. Water comes into direct contact with patients' blood across the dialyzer membrane rather than the gut with dialysis fluid. Small molecules, in particular, can freely diffuse across the membrane into the blood. As a result, it is critical that dialysis water be adequately and appropriately treated before coming into direct contact with the patient.

- 3. Finally, most dialysis patients have little to no kidney function. The kidneys may compensate for increased intake of certain substances from food and drink that would otherwise accumulate in the body. Dialyzing with pure water protects the body from substances that cannot be effectively eliminated.

HOW DOES AN INDIVIDUAL CAN ENSURE THAT HOME HEMODIALYSIS WATER IS PRODUCT WATER?

NETSOL policies and procedures outline testing requirements to ensure that the water treatment system in your home produces safe, ultra-pure water or product water that meets or exceeds AAMI standards. This test is performed before the equipment is used for the first time and at least annually thereafter. The water quality and mixed dialysate will be tested at regular intervals, usually monthly, to ensure that bacteria growth does not exceed allowable, safe limits and that the disinfection schedule of home dialysis equipment is adequate.To ensure that the carbon filters remove the chemicals from the water, one will be trained to test for this before the start of each treatment if a RO machine is used.

CONCLUSION

It is critical to convert tap water into ultra-pure water or product water for dialysis treatments in order to protect the patient from harm or injury. As a result, NETSOL WATER SOLUTION is here to supply a RO Machine for kidney dialysis. Furthermore, the dialysis center's biomedical technicians will ensure that the dialysis equipment is working properly, and the training nurse will ensure that the patient or caretaker is well trained to operate the system and perform required safety tests.