What is the difference between mechanical aeration and diffused aeration?

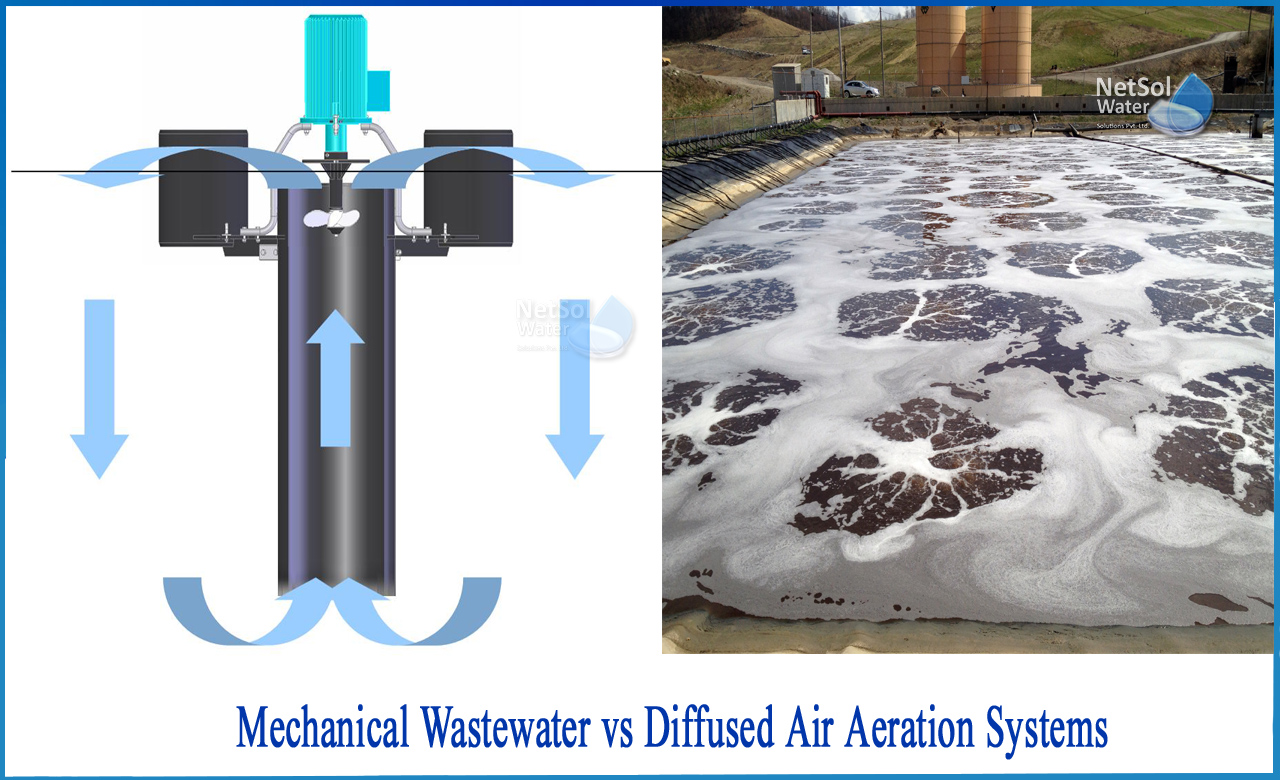

Mechanical aeration and diffused aeration are the two primary types of aeration systems. Mechanical aeration takes place at the top of a tank or lagoon, whereas diffused aeration occurs at the bottom. Older aeration systems are frequently mechanical systems that have reliably serviced their facilities for years. However, as technology advances, the wastewater industry evolves, and more and more facilities resort to dispersed aeration.

Aeration systems for diffused wastewater

Aeration is an important aspect of the wastewater treatment process, especially during the secondary treatment stage. It incorporates oxygen into the wastewater to allow aerobic bacteria to breakdown biosolid particles in the water. During the activated sludge phase, when bacteria feed on organic matter until flocs of matter and bacteria settle out and produce sludge, aeration is very important. The sludge, along with its microorganisms, is recirculated to aid in the breakdown of organic materials in the wastewater.

Aeration systems for diffused wastewater are an important part of this process. To offer a very effective aeration procedure, they pump little, less concentrated volumes of air into the liquid.

What is a diffused aeration system and how does it work?

A diffused aeration system is normally vertical in operation. It produces high concentrations of bubbles towards the bottom of a wastewater treatment plant's lagoon or tank. Onshore blowers, pipes, and diffusers are typical components of the system. Compressed air is pumped via pipes and filtered into the water via diffusers, causing small bubbles to form. As the bubbles ascend, they displace and mix the water, creating a spiral flow pattern and transporting oxygen into the water column to aid bacteria in their activity.

The diffusers usually cover as much of the floor as possible while still enabling workers to roam about and do maintenance. This complete covering ensures that oxygen is distributed evenly. The volume and type of sewage, as well as the size of the treatment tank, may be used to estimate the number of diffusers and blowers required.

Fine bubble and coarse bubble diffuse aeration systems are the two primary types of diffuse aeration systems. Fine bubble aerators improve aeration and efficiency, whereas coarse bubble aerators are better at mixing and raising dissolved oxygen levels. Because each type of bubble aerator requires a different amount of airflow, plant operators must select blowers and pipes accordingly.

Aeration systems for mechanical wastewater

Mechanical aeration systems, unlike diffused aeration systems, employ propeller blades and quickly rotating shafts instead of flexible membranes and minuscule bubbles. They usually allow for better localised mixing and higher localised dissolved oxygen concentrations, but they lack some of the advantages of diffused aeration.

What is a mechanical aeration system and how does it work?

A horizontal mechanical aeration system is used in most cases. A pump and tubing, or a motor that spins a propeller, make up the system. Water is scooped up and pushed out by the mechanism. This churning produces a current that allows for mixing. The water sucks in and absorbs air as it churns. The device continually adds additional air to aerate and mix the aerated water with the remainder of the water in the tank or lagoon.

The majority of mechanical aeration systems are modular, meaning they only require one piece of equipment to be installed. Multiple systems can be installed in a tank to provide complete coverage. Surface aeration systems usually necessitate the presence of buoys at the wastewater's surface.

Why is diffused air the most efficient aeration system?

Diffused aeration systems are far and away the preferable alternative for cheaper system costs, durable, state-of-the-art equipment, and a reduced burden of repairs and replacement for wastewater treatment facilities and maintenance workers. They improve oxygen transfer and aeration efficiency, promote consistent mixing, and maintain high oxygen levels, allowing beneficial aerobic bacteria to grow and work effectively.

Conclusion

Netsol Water is a global leader in excellent solutions and service. Our products provide cutting-edge designs, cutting-edge engineering, and time-tested quality to keep wastewater treatment systems running smoothly.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.