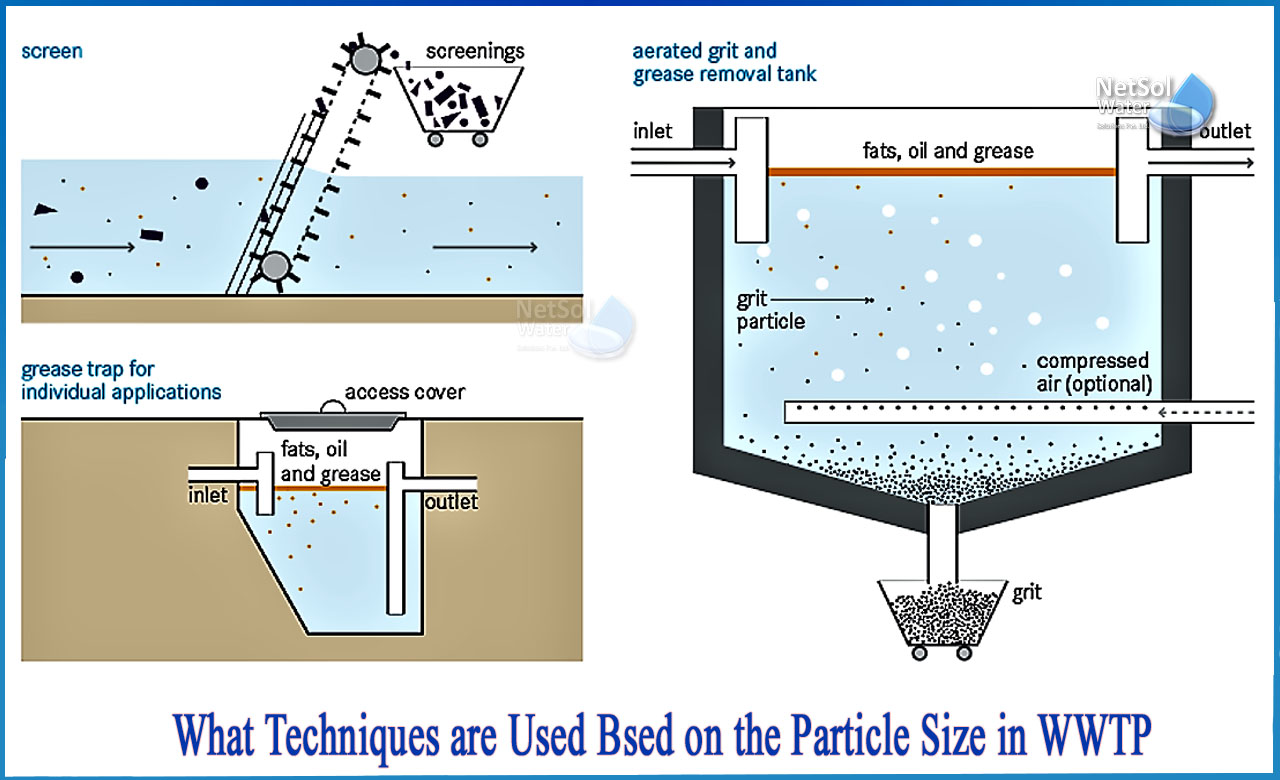

What techniques are used based on the particle size in WWTP?

Many techniques have been developed to separate substances based on particle size. Some of these techniques have a wide range of applications. Some of them are only applicable to certain sizes.

A partial list of particle sizes and the techniques that can be used is shown below.

Diameters ranging from 1 m to 1 mm

· Drum filter

· Sand filter

· Cartridge filter

· Bag filter

Diameter: 100 nm - 1000 nm (0.1 m – 1.0 m)

· Microfiltration

· Ultrafiltration

Diameter less than 1 nm (0.001 m)

· Ion exchange

· Reverse Osmosis

Common measurement methods for particle size

Because different techniques measure different dimensions of the particle, different results are obtained. Each method of measurement has its own set of advantages and disadvantages.

1: Sieves

While this is an old technique, it has the advantage of being inexpensive and especially useful for measuring large particles. This is especially useful in industries like mining.

The main disadvantages of this technique are that it cannot be used to measure sprays or emulsions, and it is difficult to measure dry powders when the particles become small. Wet sieving can help to solve this problem, but the results are difficult to reproduce. Materials that are cohesive and agglomerated, such as clay, are also difficult to measure.

2: Sedimentation

This has historically been a common method used in the clay and ceramics industries.The density of the material is required, so it is not useful for determining particle size of emulsions where the material does not settle or for dense materials where the material settles quickly. Samples with mixed density components cannot be resolved accurately. Because measuring small particles is time-consuming, the process of repeating testing can be tedious.

3: Electro zone Evaluation

This technique is excellent for measuring red blood cells, but it has several drawbacks when applied to real-world, industrial materials. Emulsions and dry powders are extremely difficult to measure, and sprays are impossible to measure. It is necessary to measure in an electrolyte, and the calibration standards required are costly.

4: Laser Diffraction

This is a popular technique that is regarded as one of the most accurate and dependable. It has several significant advantages:

· It is extremely adaptable and can measure all types of particles (powders, emulsions, suspensions and sprays)

· It is extremely fast (answers can be produced in less than sixty seconds)

· It provides an absolute method of particle analysis based on scientific principles, allowing measurements to be taken without the need to calibrate any instrument against the standard.

· The technique has a very broad and dynamic range.

· A complete sample can be measured.

· The method is extremely repeatable.

The selection of different techniques is determined by several factors, including:

· The amount of pollution

· The amount of fluid to be treated

· The properties of the substance to be removed

· The order of the damage and clogging of the filter

· The quality of the filtration

· The investment

Some of the techniques are only suitable for a single use. Other techniques involve cleaning and reusing the filter; after a while (which can be several years), the filter should be replaced.The technique used to measure particle size will vary depending on the material being analyzed, and the instrument should be of high quality.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.