What is MLSS?

The concentration of suspended particles in an aeration tank which happens during waste water treatment is known as mixed liquid suspended solids (MLSS). It is often measured in milligrams per litre (mg/L). Within an aeration tank, mixed liquor is a mixture of raw or unsettled wastewater or pre-settled wastewater and activated sludge. The majority of MLSS is made up of microbes and non-biodegradable suspended materials.It is a crucial aspect of the process because it ensures that there is always enough active biomass available to absorb the applied amount of organic pollutant. This is referred to as the food to microbe ratio, abbreviated as the F/M ratio. By keeping this ratio at an acceptable level, the biomass will eat a large proportion of the food.

This reduces residual food loss in the treated effluent. Simply put, the more the biomass consumption, the lower the biochemical oxygen demand (BOD) in the discharge. It is critical that MLSS eliminates COD and BOD from wastewater in order to cleanse it. Raw sewage contains up to several hundred mg/L of BOD when it enters the water treatment process. After treatment using screening, pre-settling, activated sludge processes, or other methods, the concentration of BOD in water can be reduced to less than 2 mg/L, which is considered clean and acceptable for release to surface waters or reuse.

What is MBR treatment?

The membrane bioreactor (MBR) has evolved as a small and effective device for municipal and industrial wastewater treatment. Membrane fouling is the biggest impediment to widespread implementation of MBRs, since it dramatically affects membrane performance and longevity, resulting in large increases in maintenance and operating expenses. Finding long-term membrane fouling mitigation solutions in MBRs has been one of the most pressing issues during the previous two decades.

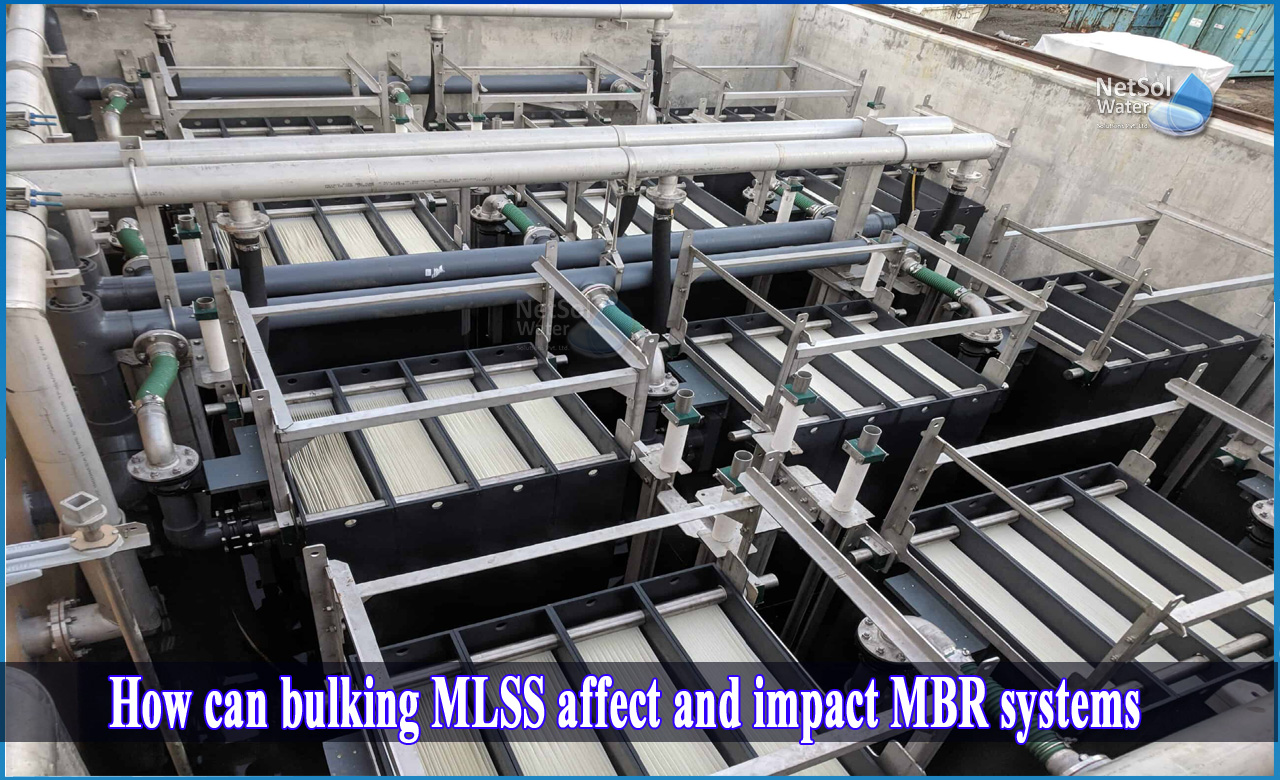

How can bulking MLSS affect and impact MBR systems?

Bacterial flocs, EPS, colloids, microsolutes, and macrosolutes are all present in the MLSS. MBRs function at substantially greater MLSS concentrations than ASP. The higher the concentration of MLSS Membranes in MBRs, however, the faster membrane fouling occurs due to excessive suspended particles. Several studies have found that when MLSS concentrations increase, membrane permeability decreases.

Operating at MLSS concentrations over 10,000 mg/L significantly increases viscosity, affecting filterability. The concentrations of both polysaccharides and proteins fractions of EPS rise with increasing MLSS concentration. At each flux evaluated, an increase in MLSS results in a substantial drop in membrane permeability and an increase in fouling rate. Thus, when MLSS concentrations grow, so does membrane fouling.

Similarly, if filamentous bacteria predominate in the MLSS, it is more likely to develop. Filamentous bulking can dramatically enhance the generation of SMPs, which in turn significantly increases membrane fouling.

A non-ideal MLSS increases the risk for biological fouling. EPS, in particular, has the potential to pollute the membrane by:

- Cake forming, which is typical and may be cleaned with a backflush.

- Pore obstruction, i.e., the solids/eps obstructs water passage through pores.

- Biofilm formation, i.e., EPS enables biofilm adhesion to membranes, ultimately closing holes.

If your biomass contains more EPS (non-filamentous bulking, foaming filaments) and filaments that might strengthen biofilms on the membrane, your membrane maintenance will entail more cleaning cycles and an earlier replacement than in a system with better conditioned MLSS. As a result, even with an MBR system, it is critical to check EPS and filaments.

Netsol Water provides a complete variety of standard and fully configurable wastewater treatment systems, as well as their comprehensive maintenance. Choosing a trained, accredited, and experienced wastewater system specialist will considerably boost your chances of long-term satisfaction with your overall system.

We have over 10 years of experience custom-designing and manufacturing wastewater treatment plants. You can schedule a conversation with our engineer or obtain an estimate by visiting our website. We can guide you through the process of determining the best solution and a reasonable price for your wastewater treatment system requirements. To begin the conversation, please contact us at +919650608473 or send an email to enquiry@netsolwater.com for further information or product purchase related query.