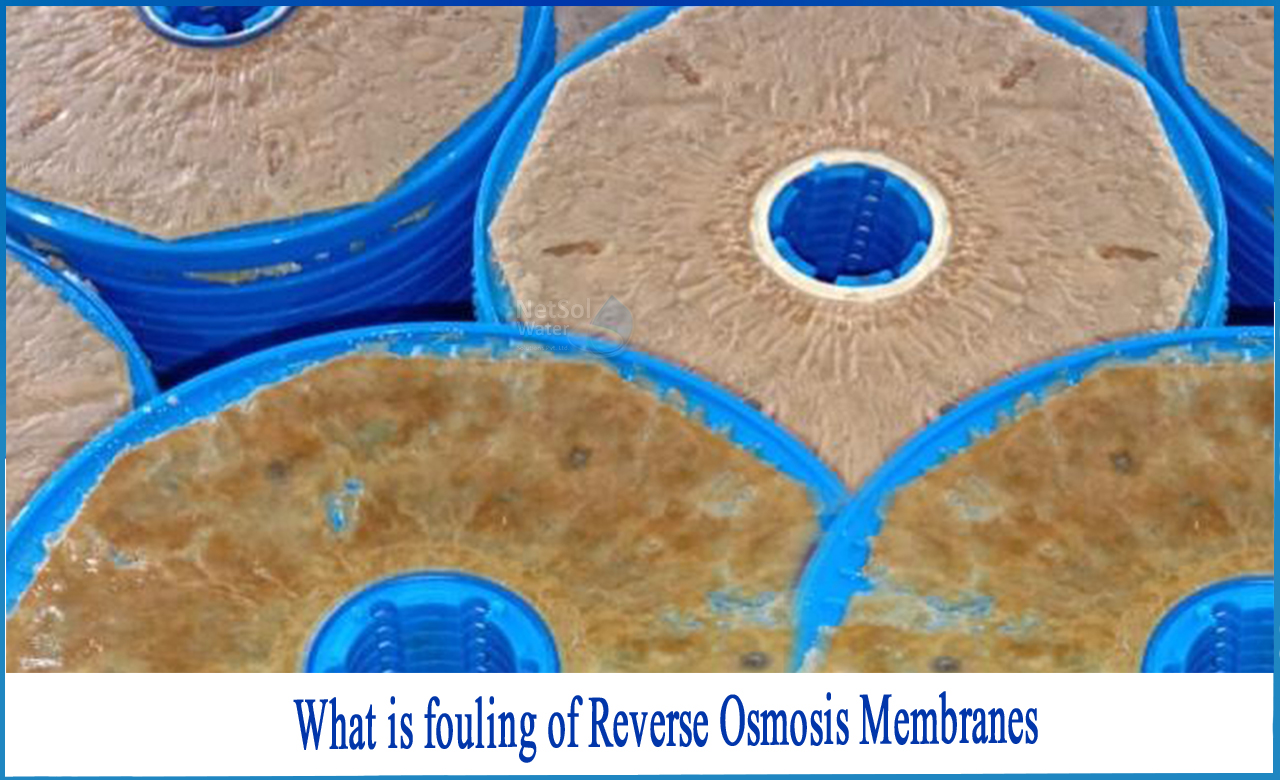

What is fouling of Reverse Osmosis membranes?

Because of its higher rejection of contaminants, lower related cost, and superior product quality, reverse osmosis (RO) is the most preferred technique for water recovery from secondary effluent (SE). Due to the greater pollutant loadings in SE and the high rejection capabilities of this membrane, fouling remains a key barrier during water recovery. The abundance of suspended particles, colloidal and organic debris, as well as a high degree of biological activity in SE, all contribute to the possibility for fouling.

Bio-fouling, inorganic/scaling, organic, and particle fouling are the four forms of fouling seen in Reverse Osmosis. Bio-fouling is the least well-understood, yet it is the most common, owing to the lack of well-developed pre-treatment alternatives. Pre-treatments have been devised to overcome other fouling processes. Dissolved and macromolecular organic molecules, sparingly soluble inorganic compounds, colloidal and suspended particles, and microorganisms are the main foulants for RO.

Membrane fouling composition

1: Calcium carbonate scale

Calcium carbonate scale can form if the scale inhibitor/dispersant addition system fails, or if the acid addition pH adjustment system fails to raise the pH of the feedwater. Setting up a transparent tube on the concentrated water pipeline aids in identifying the fouling problem as quickly as possible, and it is critical to avoid crystals deposited on the membrane's surface from harming the membrane components. By reducing the pH of the feed water to 3-5 and operating for 1-2 hours, the calcium carbonate scale found early may be eliminated. Calcium carbonate scale with a lengthy deposition period can be cleansed and removed with a citric acid solution with a low pH.

2: Scales of calcium sulphate, barium sulphate, and strontium sulphate

Sulphate scale is a mineral scale that is significantly difficult to remove than calcium carbonate scale. The failure of the scale inhibitor/dispersant addition system or the administration of sulphuric acid to regulate the pH might result in sulphate scale deposition. To avoid the crystals produced on the membrane's surface from injuring the membrane components, sulphate scale should be found as soon as feasible.

3:Scale of calcium phosphate

With high phosphorus concentration, calcium phosphate scale is more typical in municipal wastewater treatment. This type of scale is usually removed with an acidic cleaning solvent.

4: Polymeric silica scale

Silica gel scale is more difficult to remove and is caused by solubility saturation or polymerization reaction. Silica gel fouling is not the same as silica-based colloid contamination, which can be caused by metal hydroxides and organics. Using typical cleaning procedures to remove silica scale is very difficult.Chemical cleaning agents such as ammonium bifluoride have been utilized effectively, although they are extremely toxic and damaging to equipment.

5: Contamination by colloidal particles

A colloid is an inorganic material suspended in water or a particle of an organic-inorganic combination. It does not settle due to gravity alone. Iron, silicon, Sulphur, aluminium, or organic materials are common major components of colloids.

6: Natural organic matter that has been dissolved

The breakdown of nutrients in surface water or deep well water is the most common source of dissolved natural organic matter pollution (NOM). Organic pollution has a sophisticated chemical process. Humic acid is the primary organic component. Adsorption of insoluble NOM on the membrane surface has the potential to pollute RO membrane components quickly. The gel or block pollution process will commence once adsorption has occurred.

7: Deposition of microbes

Bacterial slime, moulds, fungus, and other organisms form organic deposits. It is difficult to remove such contaminants, especially when the water supply route is totally stopped. If the water supply route is blocked, clean water will have a difficult time entering the membrane element in sufficient and equal amounts. It is critical to clean and maintain the RO system, as well as the pretreatment, pipes, and ends, in order to prevent continued growth of such deposits.

What do we offer?

Netsol Water is a renowned producer of water and wastewater treatment plants. Based on client feedback and job quality, we are the most demanding organization in the water industry. We have a reputation for being the top commercial RO plant manufacturer, industrial RO plant manufacturer, sewage treatment plant manufacturer, effluent treatment plant manufacturer, and much more.

We can assist you in the following ways:

-Determining the cause of the RO system's poor performance;

-Recommending the most effective cleaning chemical for the RO membranes;

-Creating and implementing the RO membrane cleaning protocol;

-Providing the chemicals and cleaning stations.

Our USP is 24x7 customer assistance.For further inquiry, or product-purchase-related questions, give us a call on +91-9650608473 or email at enquiry@netsolwater.com.