Wastewater treatment plants are utilised in every sector to handle the enormous volume of wastewater produced each day. Its main aim and fundamental objective is the protection of the general public from health risks, brought on by untreated wastewater.

The most crucial step in any wastewater treatment plant is biological wastewater treatment, where living microorganisms are crucial to the breakdown of organic waste. The operational control parameter of MLSS must be maintained for the best wastewater treatment results.

Let’s understand the concept of MLSS and the purpose of MLSS in wastewater treatment.

What is MLSS (Mixed Liquor Suspended Solids) in wastewater treatment?

Mixed Liquor Suspended Solids, or MLSS, is a measure of the total concentration of solids in an aeration tank, used in the wastewater treatment process. It is made up of bacteria, organic substances, and suspended non-biodegradable materials.

Moreover, MLSS is thought to be a mixture of suspended particles and influent wastewater, which acts as a barometer for the system's biomass.

Optimization of MLSS: Good MLSS in wastewater treatment

1: Around 1500 mg/l to 5000 mg/l of MLSS are employed in traditional activated sludge wastewater treatment facilities.

2: According to studies, Membrane Bioreactors (MBRs) with MLSS concentrations range between 10,000 and 12,000 mg/l.

For smaller aeration tanks where the treatment level is constant, higher MLSS concentration is advantageous. Higher MLSS is indicated by increased BOD loading, thickening sludge, high flow rates, insufficient settling times, and nutritional deficiency in the biomass.

Nevertheless, aeration efficiency may decrease as MLSS concentration rises. Low MLSS therefore denotes that the DO concentration is not being maintained, fewer organisms are surviving, the flow rate is falling due to the absence of microorganisms, and both stalked and free-swimming ciliates are declining.

This means that an appropriate level of MLSS concentration must be maintained, for wastewater treatment plants to function at their best. That would be easier to accomplish if we understood the bacterial activity in the system.

Methods for MLSS assessment in Wastewater Treatment

MLSS in the wastewater treatment process can be tested and evaluated utilising a variety of techniques. During peak flow, a daily inspection is preferred in large wastewater treatment plants.

Significance of MLSS in wastewater treatment

It helps with return activated sludge (RAS) flow optimisation for a constant load, during influent flow and load-variation periods.

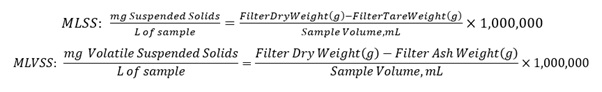

How is MLSS calculated?

Step 1: Gathering an MLSS grab sample and running it through the filter make up the first phase.

Step 2: To dry the residue, the filter should be burned for approximately 15 to 20 minutes in a muffle furnace (550 degrees).

Step 3: The residue needs to be transferred to a desiccator for cooling in the third stage once the filter has cooled.

Step 4: In the final step, weigh the remaining filter residue.

By dividing the MLSS concentration (kg/m3) by the tank volume, one can get the total weight of MLSS contained within an aeration tank.

Relationship between MLSS and Oxygen uptake rate (OUR)

The oxygen uptake rate is the rate at which the biomass consumes oxygen. Also, it helps in the evaluation of microbial activity.

Toxins are harming MLSS when oxygen uptake rate is lower than usual. Organic overloads are indicated by increased levels. The quick recovery of a high oxygen uptake rate to normal is another potential. It reveals that a poor food to microorganism ratio is the root cause of the low MLSS concentration.

Manufacturer and supplier of high-quality wastewater treatment plants

Netsol Water is one of the top businesses offering cutting-edge wastewater treatment solutions. We also aid in the optimisation of MLSS in wastewater treatment, and raise the effectiveness of the biological treatment process in wastewater treatment plants.

Municipalities can contact our water treatment experts, for a variety of advanced wastewater treatment techniques. We also have been providing wastewater treatment services to different industries for many years. These services include water clarifying, sludge dewatering, chlorination and de-chlorination, phosphorus removal, odour control, etc.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.