What is Activated sludge process?

Activated sludge is a process that uses bacteria (to break down biodegradable organic matter) and air (breathing oxygen) to treat wastewater.

Activated sludge represents a mixture of microorganisms and suspended solids. Bacterial cultures are cultivated in a processing unit to break down organic matter into carbon dioxide, water and other inorganic compounds.

A typical activated sludge process consists of the following basic components:

1) Wastewater/Pre-treatment plant that separates solids carried with wastewater,

2) Reactor-treated waste that keeps microorganisms suspended, aerated, and contacted,

3) Liquid-solid separation;

4) Activated sludge,

5) A sludge recycling system for returning to the beginning of the process.

There are many types of activated sludge processes, including variations on aeration methods and methods of returning sludge to the process. The activated sludge process provides efficient BOD, COD, and nutrient removal when professionally designed and properly operated. The process itself is flexible and many changes can be made to suit specific requirements (such as nitrogen removal).

This is a complex combination of microbiology and biochemistry involving different types of microorganisms. In activated sludge plants (ASPs), bacteria expel sticky substances that envelop small particles that are carried into wastewater. The particles stick together to form flakes of gel-like material that form the carrier on which the microorganisms are present. This is chocolate brown activated sludge.

It aerates activated sludge to dissolve oxygen and makes organic matter (BOD) available to bacteria. Organic matter and food adhere toactivated sludge. Oxygen dissolved in water allows bacteria to utilize food (BOD) and convert ammonia into nitrates. The tank must be large enough to allow sufficient contact time (retention time) between wastewater and activated sludge against chemical changes.

What is Activated Sludge Return (RAS)?

At the end of the process, activated sludge is still highly active biomass, but is now mixed with treated wastewater. It will be transferred to a settling tank (secondary purification device) so that it can be separated from the treated wastewater. Wastewater is discharged into rivers and some form of tertiary treatment takes place.A part of the remaining sludge is sent back to the treatment unit, called return activated sludge.This allows you to operate the process as a continuous cycle.

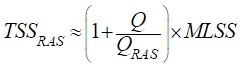

Formula used for RAS calculation:

1. Total Suspended solids

Where, Q = discharge

MLSS = Mixed Liquor suspended solids

Suspended solids adversely affect all aspects of the circulating aquaculture system, so the first target of all treatment systems are solid waste disposal. Suspended solids are the result of faeces, biofloc (Dead and live bacteria). The size of these suspended particles is from cm to Micro meter (µm). The importance of rapid and complete solid removal from the culture vessel cannot be fully emphasized. Everything else fails if this key function is not fully performed.

2. Return sludge Rate

Return sludge rate in MGD

= Settled solids, mL x (Flow, MGD) / (1000 mL - Settled solids, mL)

3. Return Activated Sludge (RAS)

RAS

=(Settled volume, mL/L) x (Influent flow rate, MGD) / (1000 mL/L) - (Settled volume, mL/L)

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.

_TSS.jpg)