What is Vapor-compression?

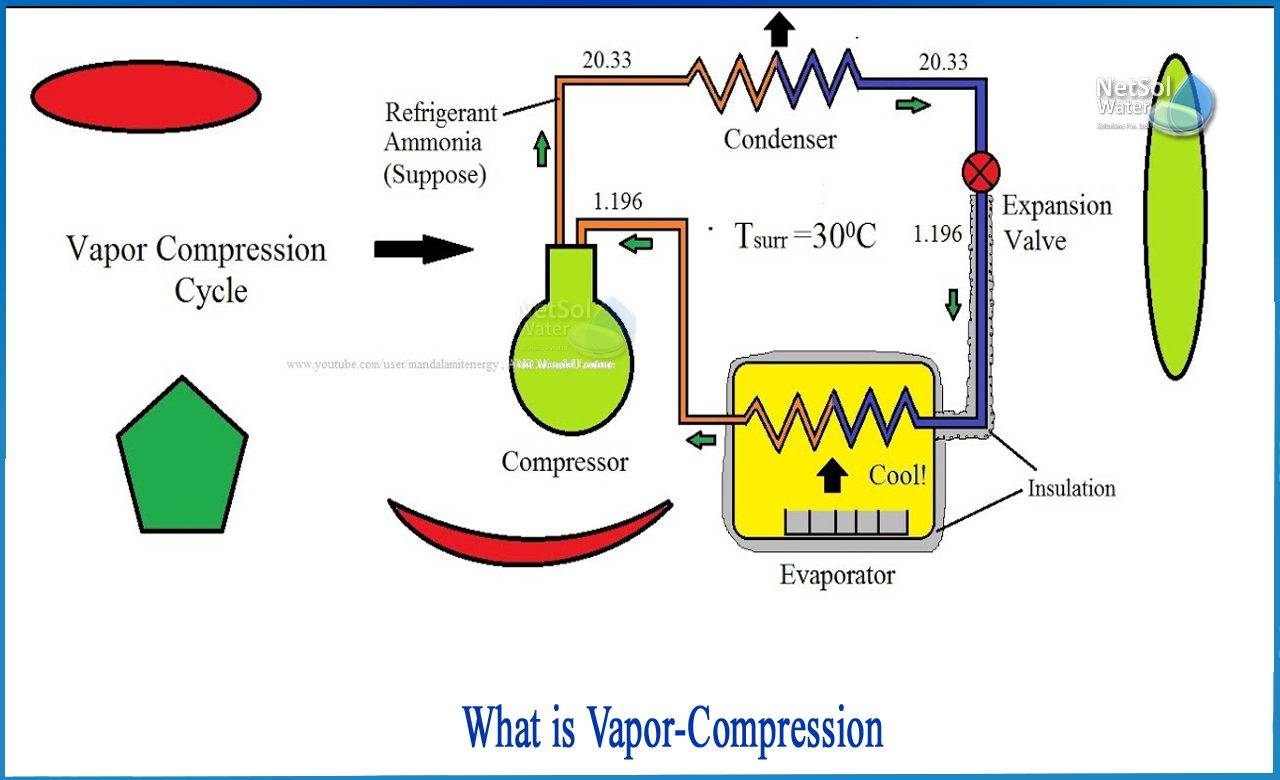

Vapor-compression is a distillation technique that involves the application of heat generated by compressed vapor to evaporate sea or saline water. Since, vapor compression increases both the pressure and temperature of the vapor, the latent heat rejected during condensation can be used to make more vapor.

Compressing water vaporcan be accomplished in two ways

The first approach recycles vapor from the desalination process by using an ejector system powered by steam at manometric pressure from an external source. Ejectocompression or thermo compression is the name given to this type of compression.

In the second approach, water vapor is compressed using a mechanical device that is usually powered by electricity. Mechanical vapor compression is the name given to this type of vapor compression (MVC).

There are two variations of the MVC process:

· Vapor compression (VC) and

· Vacuumvapor compression (VVC).

VVC denotes systems in which evaporation occurs at sub-atmospheric pressures, while VC denotes systems in which evaporation occurs at manometric pressure (under vacuum).

What process is followed?

A compression turbine, for example, is used to mechanically power the compression. As vapor is produced, it is transferred to a heat-exchanging condenser, which converts it to water. The resulting fresh water is stored, and the heat lost during condensation is passed on to the remaining feedstock.

In terms of energy usage and water recovery ratio, the VVC process is the most efficient distillation method currently available in the market. The system is called a "clean" process because it is electrically driven. It is also very reliable and simple to run and maintain.

Vapor-compression evaporation

Vapor-compression

The process of evaporation in which a blower, compressor, or jet ejector is used to compress and therefore increase the pressure of the vapor produced is known as evaporation. Because the condensation temperature rises as the vapor's pressure rises, the same vapor can act as the heating medium for the "mother" liquid or solution being concentrated, from which the vapor was formed in the first place. Without compression, the vapor would be at the same temperature as the boiling liquid/solution, preventing any heat transfer.

Vapor compression distillation is another name for it (VCD). This evaporation process is commonly referred to as MVR when compression is accomplished by a mechanically driven compressor or blower (mechanical vapor recompression). The process of compression using high-pressure motive steam ejectors is commonly referred to as thermocompression or steam compression.

Advantages of Thermal Vapor Compression

• The major product is water or water containing only trace amounts of organic compounds.

• The distillate can be easily evaporated to supply the ejectors with vapors.

• The heating medium is at the desired temperature level.

• There is a moderate temperature difference between the upper and lower temperatures.

• No moving components

• Low wear

• High operational safety

• Lower investment costs

• Simple and effective design

Conclusion

Netsol Water is the best manufacturer for water and waste water treatment plants in India. Out main motto is to give more and more clean water to our clients in Delhi NCR and all over India.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.