What is agglomeration and What are the methods used?

Solid particles adhere to each other or to surfaces in a natural phenomenon known as agglomeration. Agglomeration can produce issues like caking, accumulation, and lumping when it's not wanted, but it's also a common particle-size expansion procedure in the chemical process industries (CPI) to find ways to overcome hurdles like segregation, problematic flow, and low bulk density, among others. Agglomeration can also aid in particle size distribution control and the reduction of potentially dangerous elements of solids such as dust.It can also be a valuable procedure for improving powder characteristics and obtaining high-quality products by using controlled particle enlargement.

One of the four-unit activities of mechanical process engineering is size enlargement through agglomeration (powder and bulk solids technologies). It entails mixing particles to produce new particle sizes in products. Granules, briquettes, extrudates, pellets, bricks, tablets, or compacts are examples of products that come in a variety of formats and/or have brand names.

To obtain a product with bigger particle dimensions, size enlargement by agglomeration is used. The resulting object appears to be nothing more than a new unit. Binding mechanisms hold the original solid particles together in the structure, which are often fully unchanged in shape and size. Porosity void spaces between the agglomerate-forming particles is also present in the new entity. This porosity is useful in the production of easily dispersible food and pigment granules, as well as "designer" foods and catalyst carriers. It is unfavourable in highly reactive materials where passivation is achieved through pressure agglomeration (densification).

The bulk properties of particulate materials are also altered by agglomeration, usually for the better. Larger particles produce less dust, have better flow characteristics, and are less likely to stick. Even with challenging materials, storing, handling, and feeding materials with large particles is less dangerous.

Methods of Agglomeration

Tumble/growth agglomeration, pressure agglomeration, and heat agglomeration are three strategies for enlarging particle materials (sintering).

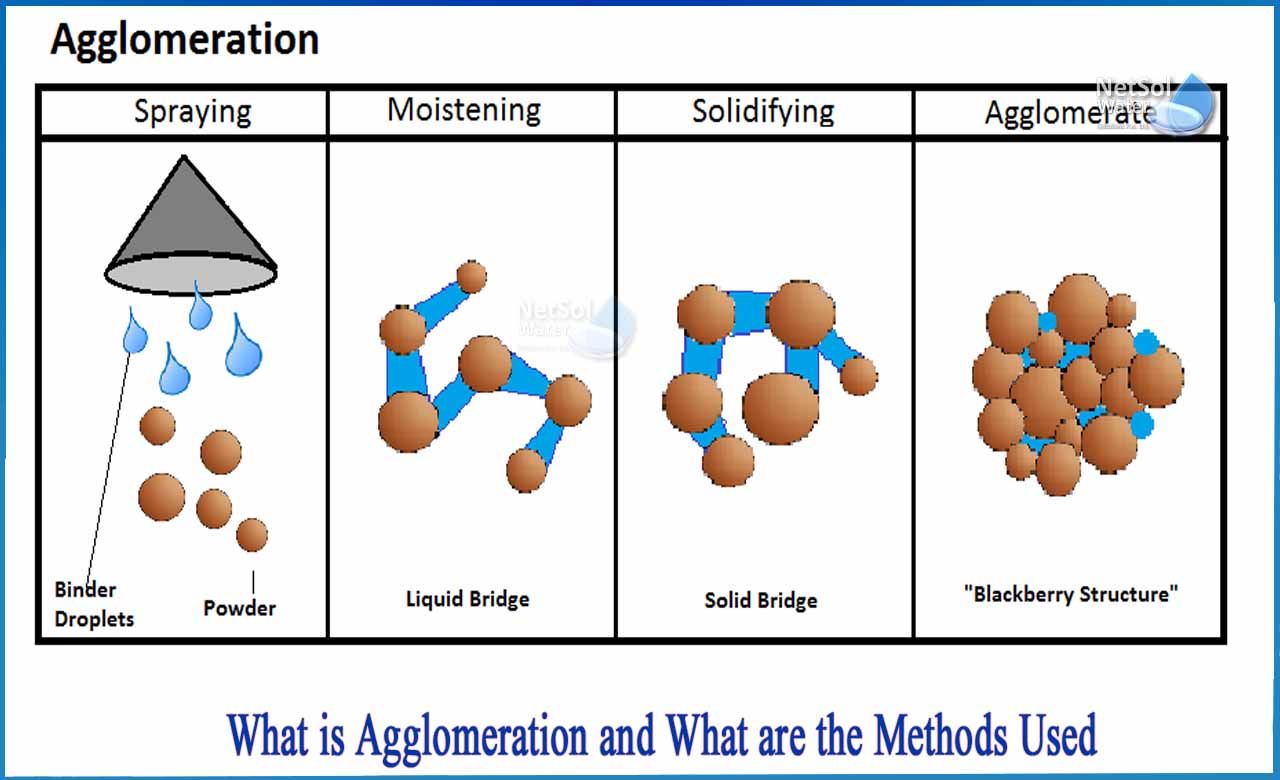

1: Tumble /Growth Agglomeration: The adherence of particles to one another in tumble/growth agglomeration is controlled by a competition between quantity separation and surface-related adhesion forces. The sum of all separation forces in the system (e.g., gravity, inertia, drag, etc.) must be less than the attraction forces between adhering partners to cause permanent adhesion. Even when the agglomerate-forming particles are dry, adhesion happens spontaneously when solids are in the micron, submicron, or nano range (beginning at around 10 m). Adhesion pressures must be established or strengthened in the case of bigger particles by the addition of binders or conditioning. Furthermore, a high concentration of particulate materials must be provided to maximise the likelihood of particle collisions. In inclined discs (pans), powder mixers, revolving drums, and fluidized beds, such conditions can be achieved.

2: Pressure Agglomeration: External forces are applied to essentially dry particle solids in more or less closed dies that define the geometry of the agglomerated result to create huge entities in pressure agglomeration. There are low, medium, and high-pressure approaches since the level of force exerted is the primary distinguishing aspect. Materials are passed (extruded) through apertures in die plates in low and medium-pressure agglomeration; punch-and-die and roller presses are employed in high-pressure agglomeration. To produce granular items, compacts are frequently crushed and screened.

3: Heat Sintering Agglomeration: Atoms and molecules begin to migrate across the interface where particles meet in agglomeration using heat (sintering). This occurs at a specific elevated temperature, which varies depending on the substance. Diffused matter generates bridge-like structures between the surfaces when still solid, which solidify upon cooling. This phenomenon occurs in the posttreatment of agglomerates, resulting in strong permanent linkages and/or particular final qualities in sections that might have been made using any of the previous agglomeration processes.

Agglomeration isn't usually utilised to increase size. Agglomeration alters or improves the characteristics of particulate particles or modifies the surfaces of solids in various technologies. Coating is the oldest of these methods, and it has evolved into a key sector of solids processing that is employed in practically every industry, often for functionalizing agglomerate surfaces. Other cutting-edge technologies manipulate single particles.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.