Primary Sedimentation Tanks for Sewage Treatment Plants

Primary sedimentation tanks play a crucial role as the first major step in wastewater treatment. These tanks remove a significant portion of suspended solids from incoming sewage, reducing the load on subsequent stages and facilitating efficient operations. By leveraging gravity, they separate and settle heavier particles, preparing sewage for further treatment.

Purpose and Importance

The main purpose of sedimentation tanks is to separate and remove settleable solids from sewage. These solids, called primary sludge or raw sludge, consist of organic and inorganic materials that can be effectively removed through physical separation.

Removing solids early offers several benefits:

1. Reducing organic load on biological treatment stages, improving efficiency and minimizing required capacity.

2. Preventing solids accumulation in downstream processes, avoiding clogging and equipment wear.

3. Facilitating collection and disposal or further treatment of separated solids (sludge).

Design and Operation

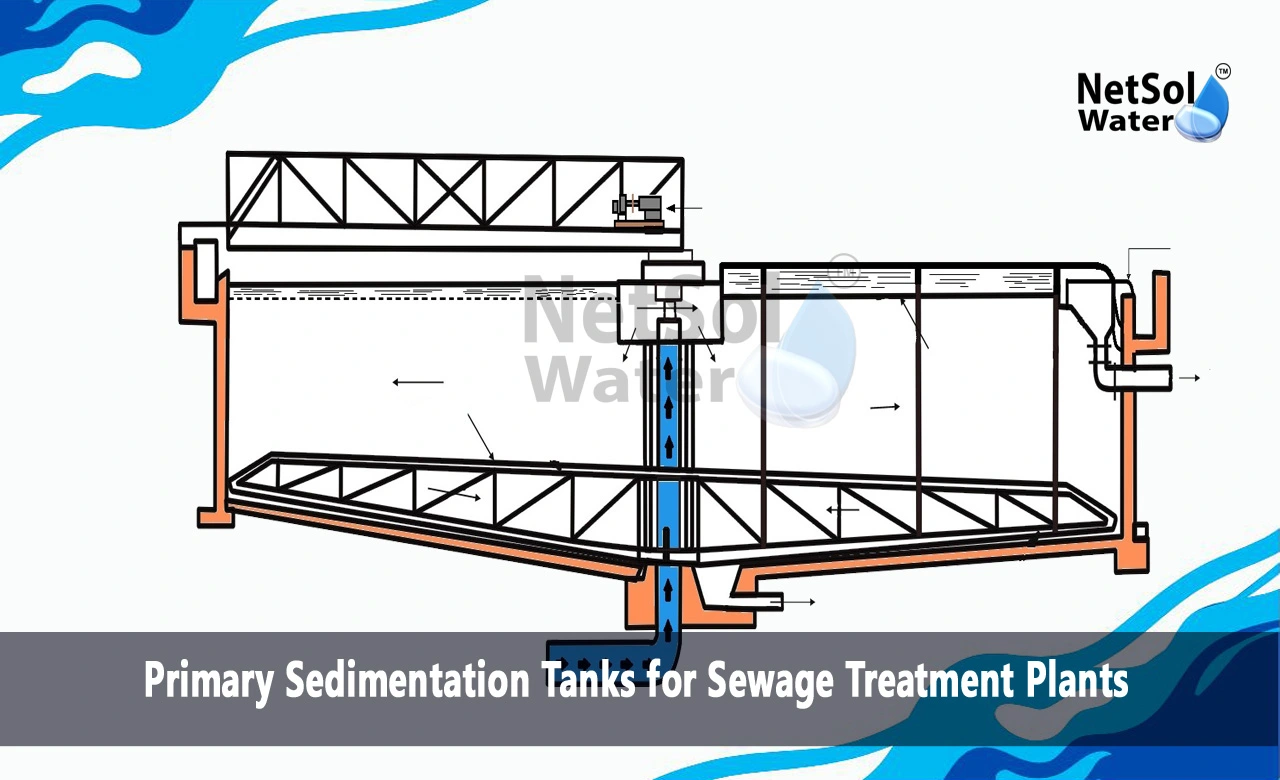

Sedimentation tanks provide sufficient retention time and quiescent conditions for effective particle settling. Rectangular or circular shapes are used, with circular tanks being more common due to improved flow patterns and space efficiency.

Key design factors include:

1. Inlet and outlet structures for even sewage distribution and clarified effluent collection.

2. Tank geometry affecting flow patterns and sludge collection efficiency.

3. Detention time, typically 1.5 to 2.5 hours, allowing adequate solids settling.

During operation, sewage enters through the inlet, where baffles are distributed evenly. As sewage moves through the tank, heavier particles settle to the bottom as sludge. Clarified effluent with reduced solids exits through the outlet, equipped with weirs or ports to maintain water level.

Sludge Removal and Handling

Efficient sludge removal maintains tank performance. Sludge is typically removed from the bottom using mechanical scrapers or suction systems, gently transporting settled sludge to a collection sump or hopper for pumping to subsequent treatment processes.

Sludge handling and treatment are critical components of wastewater treatment. Primary sludge undergoes methods like thickening, stabilization, and dewatering before final disposal or beneficial reuse, such as land application or energy recovery through anaerobic digestion.

Advanced Primary Treatment

In some cases, primary sedimentation tanks can be enhanced with additional processes known as advanced primary treatment, including:

1. Chemical addition of coagulants or flocculants to promote particle agglomeration and improve settleability.

2. Sedimentation aids like ballasted flocculation to enhance settling and increase solids removal efficiency.

3. Dissolved air flotation (DAF), where air bubbles cause solid particles to float for removal instead of settling.

Maintenance and Monitoring

Regular maintenance and monitoring ensure optimal tank performance, with considerations such as:

1. Routine inspection and cleaning of inlet and outlet structures.

2. Monitoring and adjusting sludge removal mechanisms.

3. Periodic desludging to remove accumulated solids.

4. Addressing potential odor issues.

5. Implementing appropriate safety measures for personnel.

Conclusion

Primary sedimentation tanks play a vital role by effectively removing settleable solids from incoming sewage. By reducing organic load on subsequent stages and facilitating efficient sludge management, they contribute significantly to overall sewage treatment effectiveness and sustainability.

As communities prioritize environmental protection and resource recovery, the importance of these tanks will continue to grow. With advancements in design, operation, and maintenance, they will remain crucial components in safeguarding public health and preserving water resources for future generations.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.