What is sludge dewatering?

Sludge dewatering is the process of separating sludge into liquids and particles in order to reduce waste. Sludge dewatering can be accomplished by using a variety of methods, which include plate & frame and belt filter presses, screw pressing,centrifuging,and geo-membranes. Other alternatives are available in addition to these.

Dewatering does not treat the sludge or liquid, rather, it just separates the solid and liquid components so that the distinct phases may be handled more easily and cost-effectively for eventual disposal. Both the solid and liquid components of the sludge may include contaminants that must be treated individually once it has been dewatered.

The two major goals of sludge dewatering are to reduce waste and improve overall disposal cost efficiency. Furthermore, stabilised sludge may be handled more safely, reducing health risks. Some sludge’s have a high beneficial reuse value and can be applied to the soil.

What is sewage sludge made of?

Sewage sludge contains both inorganic and organic materials, as well as high levels of some plant nutrients, as well as much lower levels of several trace elements and organic compounds, as well as pathogens. Sewage sludge composition varies greatly based on the wastewater composition and treatment procedures utilised.Because of mandated industrial pre-treatment of wastewater, the concentrations and incidence of trace metals and other contaminants in sewage sludge have dropped significantly during the last 20 years.

Some of the remaining trace elements and organic compounds come from human waste and consumer product disposal, but corrosion of plumbing systems and water mains accounts for a large part. Because stormwater drains in certain cities are connected to sanitary sewer systems, some contaminants from the street debris and rainwater are retained in the sewage sludge.

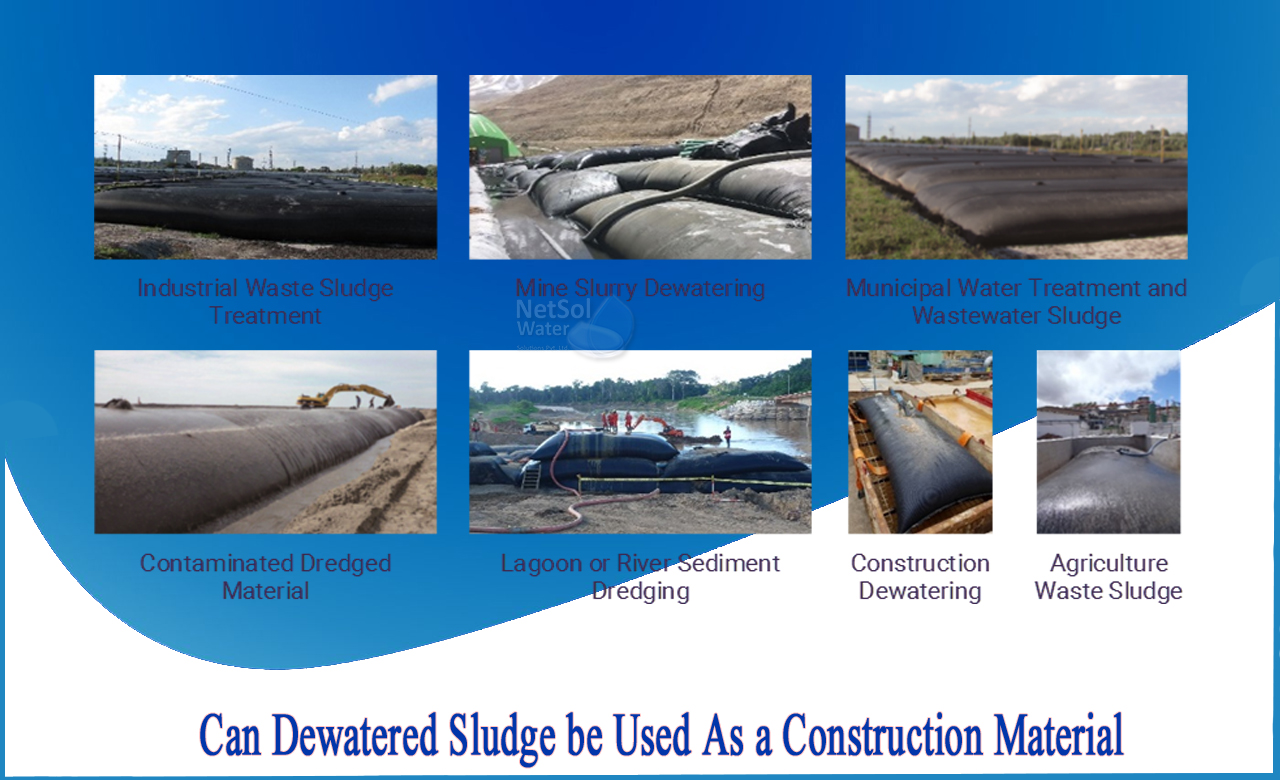

Can dewatered sludge be used as a construction material?

Due to its rising volume, excess sewage sludge produced in any municipal or industrial wastewater treatment plant becomes a severe concern. This rise is due to advancements in treatment technologies, sewage system expansion, and the creation of new industrial units.

The current approach to implementing and developing new technologies for the use of sewage sludge is to treat it as a substrate.Sewage sludge, as well as other waste materials, can be used in the construction sector. The use of sewage sludge in building materials reduces some of the more costly and energy-intensive phases of processing, and the resulting product is frequently stable and safe.

How do we know using sewage sludge as a construction material is useful?

This has been proven in studies on strength characteristics, water resistance, frost resistance, and heavy metal leaching, particularly when the amount of sewage sludge in solidified samples is minimal. The article's main goal is to describe the most up-to-date methods for utilising sewage sludge (dry, dehydrated, and raw) in building and construction materials.

Ways to use sewage sludge as a construction material

In comparison to normal solutions, stabilising sewage sludge with binding chemicals enhances the end product's durability (dewatering). When compared to mixtures without sludge, the use of sludge in concrete and mortar mixes frequently results in a reduction in strength. The strength of concrete or mortar is determined by the binder used in the mix.

Sintering sewage sludge to manufacture ceramic products (bricks, tiles) and lightweight aggregates is a viable technique, however such solutions demand more energy than other processes. Nonetheless, the resulting products are stable, and their durability, albeit lower than the control samples, qualifies them for building applications.

Sludge management strategies should be created independently due to the various physicochemical features of sludge. As a result, choosing one general and optimal approach of sludge control in construction materials is problematic.

For more information, contact Netsol Water!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.