Membrane Bioreactor Vs Conventional Activated Sludge System in STP

The treatment of wastewater stands as a challenge for growing urban areas. Modern Sewage Treatment Plants (STPs) must balance efficiency with environmental responsibility. This analysis examines two prominent wastewater treatment technologies: Membrane Bioreactor (MBR) systems and Conventional Activated Sludge (CAS) systems. Both approaches serve important roles in STPs. Yet their differences in performance create distinct advantages for specific applications. Understanding these differences helps facility managers select the most suitable treatment method. This comparative study explores the operational characteristics of MBR and CAS systems.

We will examine their effectiveness in treating wastewater across various parameters.

System Configuration and Design Elements

The fundamental design of wastewater treatment systems shapes their performance capabilities. Each system employs different approaches to achieve clean water output. Let us examine the key design elements that distinguish MBR and CAS systems.

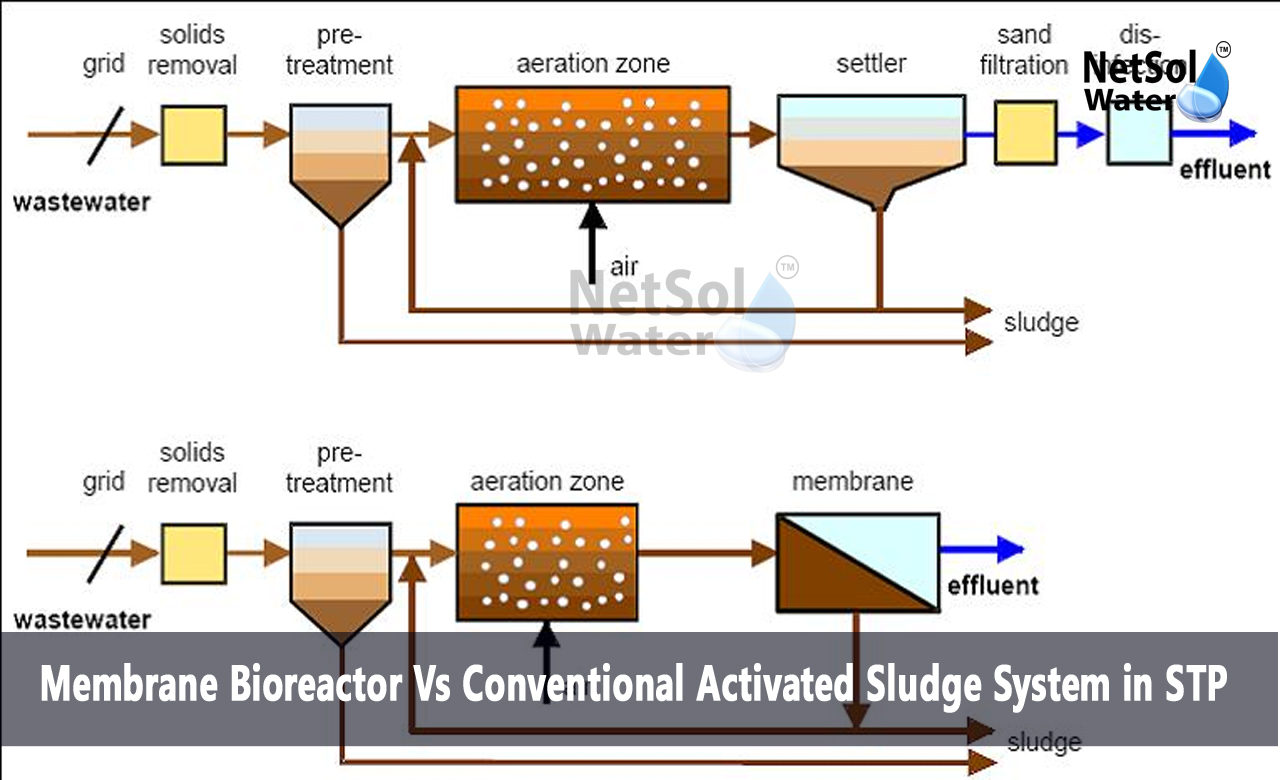

Physical Layout and Space Requirements: MBR systems integrate membrane filtration directly into the biological treatment process. This integration creates a compact footprint that suits urban installations. The system houses ultrafiltration or microfiltration membranes within the bioreactor tank. This arrangement eliminates the need for separate clarification basins. The vertical design of membrane modules maximizes treatment capacity in limited spaces.

CAS systems follow a traditional layout with separate tanks for each treatment stage. The design includes aeration basins followed by settling tanks or clarifiers. This arrangement demands more horizontal space to accommodate the sequential treatment processes. The system needs room for sludge recirculation between different treatment zones.

Equipment and Components: MBR systems feature specialized membrane modules as their core component. These modules consist of hollow fibre or flat sheet membranes arranged in cassettes. The design includes dedicated air scouring systems to prevent membrane fouling. Advanced instrumentation monitors membrane performance and controls filtration cycles.

CAS systems use conventional equipment like diffused air systems and mechanical aerators. The setup includes clarifiers with mechanical scrapers for sludge collection. Return activated sludge pumps move biomass between treatment stages. The equipment focuses on maintaining proper mixing and oxygen transfer in the aeration basins.

Operational Performance and Treatment Efficiency

The effectiveness of wastewater treatment determines the quality of treated water. Both systems achieve different levels of performance under various conditions. Let us explore their operational characteristics and treatment capabilities.

Removal of Organic Compounds

MBR systems achieve superior removal of organic matter through combined biological treatment and membrane filtration. The high biomass concentration supports the efficient degradation of complex organic compounds. The membrane barrier ensures complete retention of suspended solids. This combination produces consistently high-quality effluent regardless of influent variations.

CAS systems remove organic compounds through biological oxidation in aeration tanks. The process depends on proper settling in secondary clarifiers. Performance fluctuates with changes in influent characteristics or operational conditions. The system requires careful control of sludge settling properties to maintain treatment efficiency.

Nutrient Removal Performance

MBR systems maintain stable nitrification and denitrification processes. The high sludge retention time supports the growth of slow-growing nitrifying bacteria. The membrane separation prevents washout of biological populations. This stability enables reliable nitrogen removal even during load variations.

CAS systems achieve nutrient removal through alternating aerobic and anoxic zones. The process requires careful control of internal recycle flows and dissolved oxygen levels. Performance depends on maintaining proper food-to-microorganism ratios. The system needs regular monitoring to optimize nutrient removal efficiency.

Economic Considerations and Long-term Value

The financial aspects of wastewater treatment systems influence implementation decisions. Both technologies present different cost structures and operational requirements. Let us examine their economic implications and long-term value proposition.

Initial Investment Requirements: MBR systems demand higher upfront capital due to membrane costs and specialized equipment. The compact design reduces civil construction expenses. The system needs advanced controls and monitoring instruments. These investments translate to better treatment performance and operational flexibility.

CAS systems require lower initial equipment costs but larger construction budgets. The extensive tank volumes and clarifiers increase civil works expenses. The system needs conventional aeration and pumping equipment. The simpler technology reduces automation and control system costs.

Operational Costs and Resource Usage

MBR systems consume more energy for membrane aeration and filtration. The advanced treatment capabilities result in less chemical usage. Membrane replacement represents a significant periodic expense. The system produces less excess sludge which reduces disposal costs.

CAS systems have lower energy requirements for basic aeration and pumping. The process might need additional chemicals for settling enhancement. The higher sludge production increases handling and disposal expenses. The system requires more operator attention for process control.

Conclusion:

The choice between Membrane Bioreactor and Conventional Activated Sludge systems shapes the future of commercial STPs. Each technology offers distinct advantages for specific applications. We welcome you to discuss your wastewater treatment needs with our expert team. Contact us today to explore the best treatment solution for your facility. Our specialists will analyze your requirements and recommend the most effective system configuration.

Contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com