What is the use of FlocClay in waste water treatment plant?

The separation of a solution, most frequently the removal of debris from a fluid, is referred to as flocculation. The term is derived from the word floc, which refers to flakes of material; so, once a solution has been flocculated, the sediment has aggregated into larger aggregated flakes, making it easier to detect and remove. This process can happen naturally or be produced by using flocculants and/or physical means.

What exactly are flocclay elements?

Flocclay are chemicals that stimulate the agglomeration of tiny particles in a solution, resulting in the formation of a floc, which subsequently floats to the top (flotation) or settles to the bottom (settling) (sedimentation). This may then be extracted from the liquid more readily.Flocclay can be organic or inorganic, and it is available in a variety of charges, charge densities, molecular weights, and morphologies.

Organic polymeric flocclay are the most often used today because of its capacity to produce flocculation with a minimal dosage. Nonetheless, their lack of biodegradability, as well as the associated dispersion of potentially harmful monomers into water sources, is driving researchers to shift their focus to more environmentally friendly biopolymers. The downside is that they have a shorter shelf life and need a higher dosage than organic polymeric flocclay. To address this, integrated solutions are being developed in which synthetic polymers are grafted onto natural polymers to provide customized flocculants for water treatment that offer the best of both worlds.

What is the purpose of flocclay?

Flocclay is employed in a variety of sectors, including civil engineering, earth sciences, and biotechnology, as well as brewers and cheesemakers. Flocclay, on the other hand, is most typically used in wastewater treatment for solids removal, water clarification, lime softening, sludge thickening, and solids dehydration.

Water can contain colloidal items like clay particles, bacteria, plankton, decaying plant material, or other organic matter, and coagulation and flocculation have been used to filter water since 2000BC, when the ancient Egyptians used almonds spread over vessels to purify river water.

Flocclay, which causes sedimentation, is used in both the filtration of drinking water and the treatment of sewage, storm water, and industrial wastewater.As a result, flocculants are mostly known as water treatment plant chemicals.

How does flocclay function?

Depending on the charge and chemical makeup of the solution to be separated, flocclay can be used alone or in conjunction with coagulants.

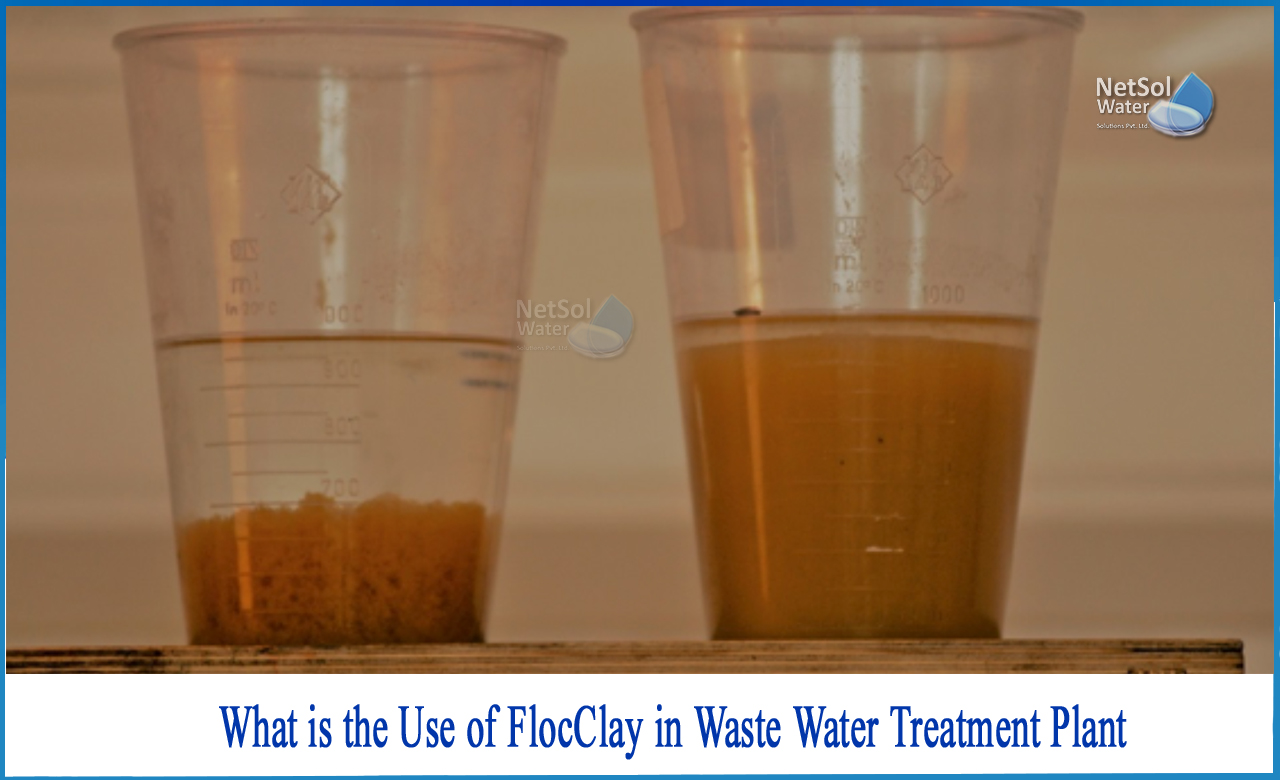

Coagulants function by destabilizing particles in a stable solution, causing them to aggregate and be linked together by flocculants. The flocculants bind the particles together to form flocs, which are subsequently removed from the solution after falling as silt or floating to the surface.

The best mix of organic and inorganic flocculants and coagulants will be determined by the kind of pollutants being removed from the water as well as the technique of separation utilized by the water treatment plant (i.e. sedimentation or floatation etc.)

What's the distinction between flocculants and coagulants?

While coagulation and flocculation are both typical processes used in water treatment and purification, they are not the same.

Coagulation is a chemical process that alters the chemical characteristics of a solution to facilitate coagulation. Coagulation means to curdle, and coagulants start the same process that occurs naturally in milk, when the pH of the liquid changes and the milk particles clump together.Coagulants are typically salts that degrade to release positive or negative charges.

Flocculation, is from the other side, is a physical process in which particles floc together, resulting in the development of a cloud and, subsequently, precipitate. Polymers that induce particles to settle into larger and larger flakes or flocs are commonly used as flocculants. Physical agitation or other operations are usually required to improve flocculation, whereas coagulation happens immediately when the coagulant is added to the solution and does not require any physical activities.

Conclusion

Flocculants are still an essential part of the water treatment process.

Netsol Water provides flocculation process for the effective operation of waste water treatment, and our team of specialists in chemical solutions for water treatment can assist you in tailoring a solution to your needs.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.