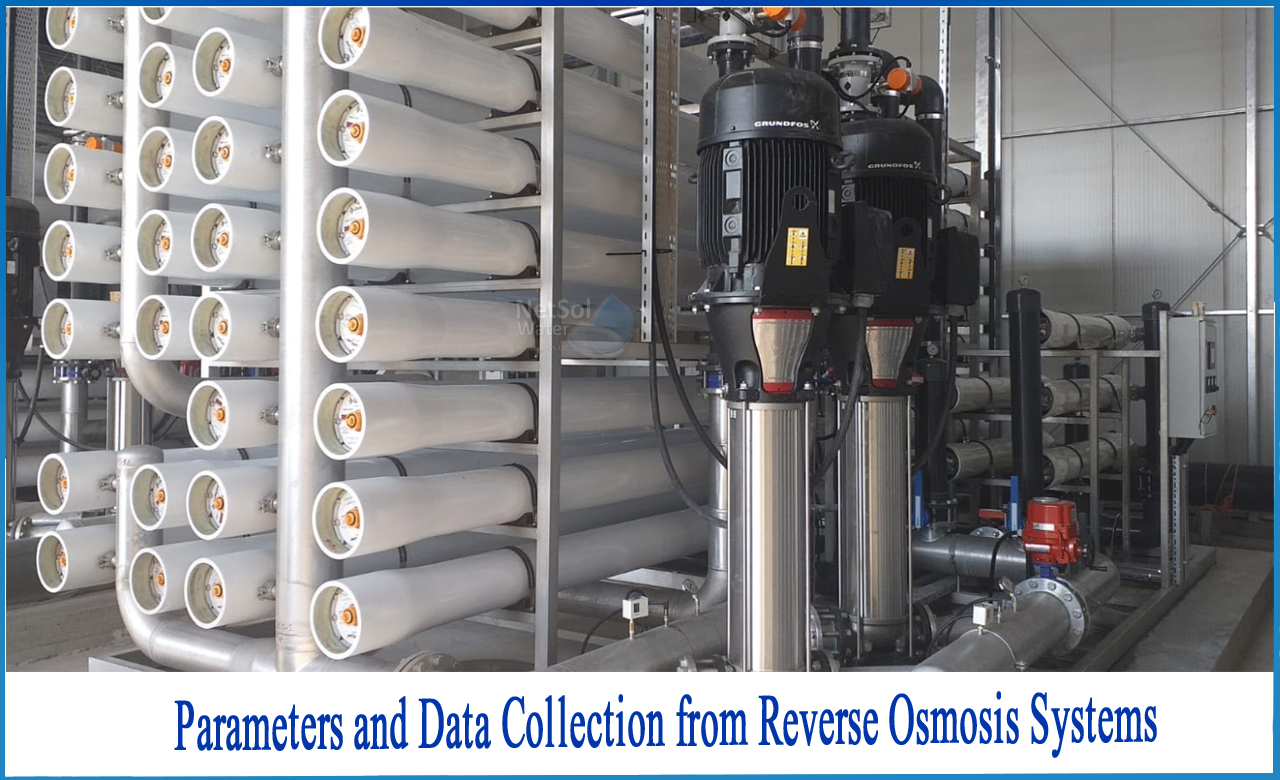

What i the Parameters and Data Collection from RO systems?

On a daily basis, precise data gathering is critical to the operation of membrane systems. The data will aid in predicting routine maintenance schedules and determining the reason of any system outages. Comprehensive data is quite valuable in determining when the membranes need to be chemically cleaned or replaced. It also warns the operator to ongoing changes such as fouling, leaking “O” rings etc.

Parameters to Monitor in RO Systems

1: Cartridge Filter Intake Pressure: Enter the water pressure at the cartridge filter housing's inlet. If a low service boost pump is present, it will have the same discharge pressure as a low service boost pump.

2: Cartridge Filter Exit Pressure: Enter the filtered water pressure from the main cartridge filter housing's outlet.

3: Differential Pressure (dP): The differential pressure should not be higher than 10-15 psid.

4: Silt Density Index (SDI): Enter the supply water's SDI. This process should be carried out on a daily basis to ensure that the feed water supply is substantially free of particle matter. Changes in the SDI can signal that the raw water supply is changing or that the pretreatment process needs to be addressed.

5: Hour Meter: Typically, an hour metre for the RO feed pump is mounted on the PLC control panel or in the MCC. The elapsed run time will be used to determine pump/motor maintenance.

6: Temperature of the raw water supply: The temperature of the raw water supply impacts the functioning of the membrane system, as well as the membrane pressure and permeate quantity. In general, when the temperature of the raw water drops, the permeate flow decreases unless additional membrane feed pressure is given to the system to compensate. Typically, the temperature is displayed on the PLC control panel.

7: Feed Conductivity: Enter the feed conductivity in microohms/cm. The feed conductivity can be displayed on the PLC control panel or on the SCADA system.

8: Total Permeate Conductivity in Microohm’s/cm: Enter the total permeate conductivity in microohm’s/cm. The total permeate conductivity can be shown on the PLC control panel.

9:Rejection (percentage): Rejection is determined by combining the feed water and permeate conductivities. Subtract the permeate conductivity from the feed water conductivity, then divide by the feed water conductivity. Multiply the resulting decimal by 100 to convert it to a percentage. The resulting figure represents the overall system rejection.

10: Feed Pressure: The feed pressure is the pressure at the first stage's membrane input. This pressure is determined by the selector valve and pressure indicator on the RO skid panel, or by a pressure transmitter reading on the PLC readout.

11: 1st Stage Concentrate Pressure: The pressure as the concentrate exits the first stage vessels is referred to as the 1st stage concentrate pressure. This pressure is collected via the RO skid panel's selector valve and pressure indicator, or via a pressure transmitter reading on the PLC readout.

12: 2nd Stage Feed Pressure: The pressure at the 2nd stage's membrane entrance is referred to as the 2nd stage feed pressure. The pressure is measured using the selecting valve and pressure indicator on the RO skid panel.

13: Total Concentrate Pressure: The pressure as the concentrate departs the vessels, prior to the concentrate control valve, is referred to as the concentrate pressure. This pressure is obtained by using the RO skid panel's selector valve and pressure indicator.

14: 1st Stage Permeate Pressure: The pressure transmitter or pressure indicator on the RO skid panel is used to acquire the 1st stage permeate pressure.

15: Total Permeate Pressure: The permeate pressure is calculated using the pressure transmitter or pressure indicator on the RO skid panel.

16: Concentrate Flow: The flow transmitter mounted to the RO skid panel displays the concentrate flow.

17:The total permeate flow divided by the feed flow is used to calculate the RO system's recovery.

18: Feed Pump Speed: The MCC display shows the Feed Pump VFD speed.

What do we offer?

Netsol Water is a renowned producer of water and wastewater treatment plants. We have a reputation for being the top commercial RO plant manufacturer, industrial RO plant manufacturer, sewage treatment plant manufacturer, effluent treatment plant manufacturer, and much more. Aside from that, our USP is 24x7 customer assistance.

For further inquiry, or product-purchase-related questions, give us a call on +91-9650608473 or email at enquiry@netsolwater.com.