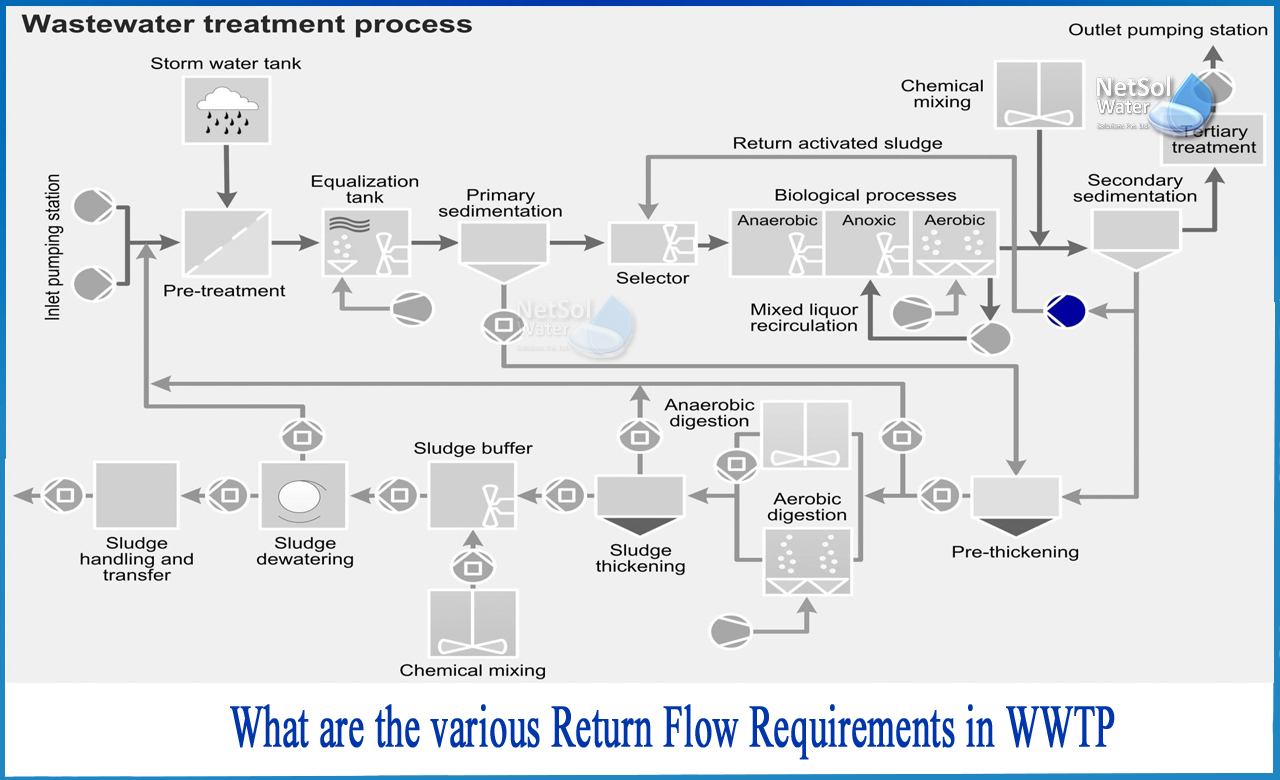

What are the various Return Flow Requirements in WWTP?

The thickened center, digested supernatant liquor, dewatered filtrate, and other waste products generated in each sludge treatment process are referred to as "return flow," and this waste is usually returned to the STP and treated.

The water quality that needs to be verified in each treatment stage's return flow is as follows:

1) SS, nitrogen, and phosphorous thickening;

2) Nitrogen, phosphorus, and COD digestion in anaerobic digestion;

3) Dewatering: Despite the fact that the items differ depending on the treatment method up to dewatering, the digestion process produces nitrogen and phosphorus.

When building STP that simply processes sludge generated by individual treatment plants, the return flow is often assumed to have no negative impact when calculating the sludge treatment return flow loads.

When there are significant temporal changes in the quantity or quality of the return flow, such actions should be taken as:

1: Establishing a return flow storage tank,

2: Temporarily storing the return flow, and

3: Returning the average return flow to the sewage treatment facilities.

On the influent side, the return destination is either the grit chamber or the primary settling tank, although, in the event of the former, it is required to sample influent sewage that does not include the return flow.

Handling of Return Flow

The return flow may be handled separately to reduce the return flow load flowing between the STP and the sludge treatment facilities in some cases. The BOD, SS, COD, nitrogen, and phosphorus loading of the return flow will increase when sludge is obtained from another treatment plant and anaerobic digestion is done.

As a result, independent return flow treatment or another type of pre-treatment before returning to the STP could be explored.There are two methods for treating return flows independently so that the treated water quality is roughly the same as the influent and returning it to the secondary treatment facility:

A:The method of treating it as far as possible by direct discharge; and

B:The method of treating it as far as possible by indirect discharge.

However, the approach should be chosen after an overall assessment of economic factors such as treatment costs and treated water stability.

Sewage Collection Systems

The traditional centralized sewerage system with deep sewers and manholes in the midst of highways is a legacy of advanced countries with significant water consumption. Although theoretically feasible, such technologies are not economically viable, especially in O&M in Indian conditions, due to high capital and O&M expenses and significant amounts of water used.

Almost all Municipal Governments are not financially self-sufficient and rely on financial help from the State and Federal Governments. In addition, in the early years, the new urban layouts are mostly fed by septic tanks, and the partially treated sewage spills uncontrollably onto streets or kutcha drains, meandering aimlessly and even stagnating here and there, resulting in numerous avoidable environmental risks.

Due to the local Government's financial situation and the complexity of maintaining a system for the entire layout, a full-fledged sewerage system is not feasible. Furthermore, in most small and medium towns, fringe parts of large cities, and slum areas, the existing per capita water supply is less than the minimum per capita water supply of 135 Lpcd required to ensure self-cleaning velocity in sewers, making a conventional sewerage system impractical.

In the interim, there is a pressing need for intermediate optional/alternative systems, pending the installation of full-fledged sewage.

If you want to know more about return flow requirements in STPs, then youcan have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.