The consumption of meat has increased in India as the economy has developed. In India, around 70% of individuals favour non-vegetarian eating. More consumption leads to the production of more wastewater, which ultimately needs to be treated.

In this blog, we will understand some of the effluent treatment techniques for meat processing industries.

Production of wastewater in the meat processing industries

While being killed, processed, and preserved, meat is very sensitive to rotting and metabolic changes. It is usually connected to food-borne illnesses as well.

The meat processing businesses have slaughterhouses where dressing or carcasses and other processes are carried out, in a sterile atmosphere for the production of hygienic meat. Due to the methods of slaughter and facility cleaning, a lot of slaughterhouse wastewater (SWW) is generated.

Characteristics of the wastewater produced by meat processing industry

This wastewater has a high concentration of pathogens, organic materials, and cleaning detergents. Because, of the low dissolved oxygen levels, this effluent can pollute the environment and even endanger human and aquatic life, when dumped directly into the water body.

Features of wastewater generated by meat processing industries

Meat processing effluents are a complex mixture of lipids, high levels of organic matter, protein, fibre, pathogens, and detergent residue. The BOD levels often vary from 150-8500 mg/L and the COD levels typically range from 500-16000 mg/L, due to the high organic load.

It is advised to classify the wastewater and reduce wastewater production at its source, due to the varied components in wastewater. However, there are approaches to treating wastewater using the various techniques listed below.

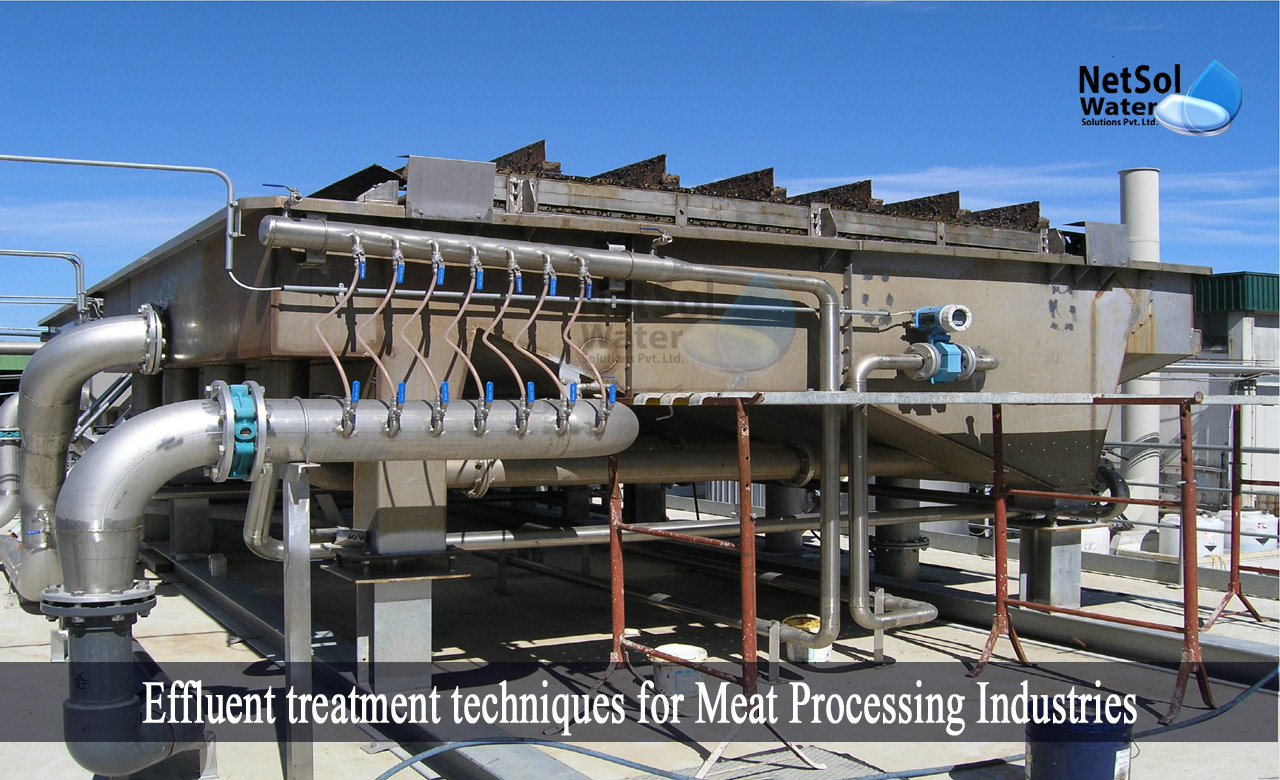

Effluent treatment techniques for meat processing industries

Similar to conventional wastewater treatment plants, the generated wastewater is treated using primary, secondary, and tertiary processes. A pre-primary treatment method is used to remove particles from the effluent, prior to the primary treatment procedure.

· Preliminary Treatment

Large solid particles are removed from SWW effluent in the initial treatment. Currently, 30% of the BOD is gone. The most frequent unit operations are strainers, sieves, and screening.

Later, the effluent is homogenised and equalised. When they settle or float, the big particles are skimmed from the effluent. The effluent then advances to the primary treatment phase of the treatment process.

· Primary Treatment

In the primary treatment, the effluent goes through a number of procedures to remove FOG from the wastewater. To get rid of the existing fats and grease, physicochemical techniques including coagulation-flocculation and sedimentation are applied.

Dissolved air flotation is a process used in some treatment facilities to raise fats, grease, and other light particles to the surface, where they form a sludge blanket. Then, with the use of scum scraping, this is skimmed off.

· Secondary/biological process

Primary and preliminary treatments don't totally clean the effluent. The soluble organic molecules from the main treatment are removed by biological treatment, also known as secondary treatment.

Lagoons with anaerobic and aerobic bioreactors remove hazardous contaminants from effluent, and thus adhere to standards.

The three technologies employed under biological treatment that are the most effective are:

1: Activated Sludge with Low Load

This technology aids in the denitrification of the effluents and the removal of dissolved organic materials. The SWW is nitrogen-free thanks to this technology.

2: SBR (Sequential Batch Reactor)

This method treats the wastewater as it enters the reactor in stages. The treated wastewater is then used for various purposes, after the effluent removes the organic debris and other nutrients.

3: Anaerobic Processes

This method allows for the removal of nitrogen and organic materials from the wastewater. Some of the carbon components in the wastewater undergo change and become biogas, carbon dioxide, and methane.

Anaerobic biological processes are extremely effective and reliable. It has cheaper operating expenses since it uses less energy, and it also has the added advantage of producing biogas. The biogas produced can be used to make power, which would lower the installation's overall energy use.

Conclusion

Our wastewater treatment products for meat processing industries can degrade complex organics, and is very efficient across a broad range of temperature and pH ranges. In anaerobic setups like UASB, anaerobic lagoon, down-flow fixed bed reactor, biogas digester, fixed-film anaerobic process, and expanded and fluidized bed process, these treatment products are strongly advised.

Choosing the best manufacturer of effluent treatment plants for the meat processing sector!

Netsol Water is one of the top businesses offering effective wastewater management solutions. Our advanced effluent treatment products aid in the treatment of wastewater, reducing organics, inorganics, FOGs, TDS levels, heavy metals and other microscopic organisms, with the elimination of unpleasant odours, etc.

The majority of the effluents discharged from the meat processing plants are treated anaerobically. Our all-natural remedy can assist in resolving issues and maintaining the plant's smooth general operation!