Overview: MBBR

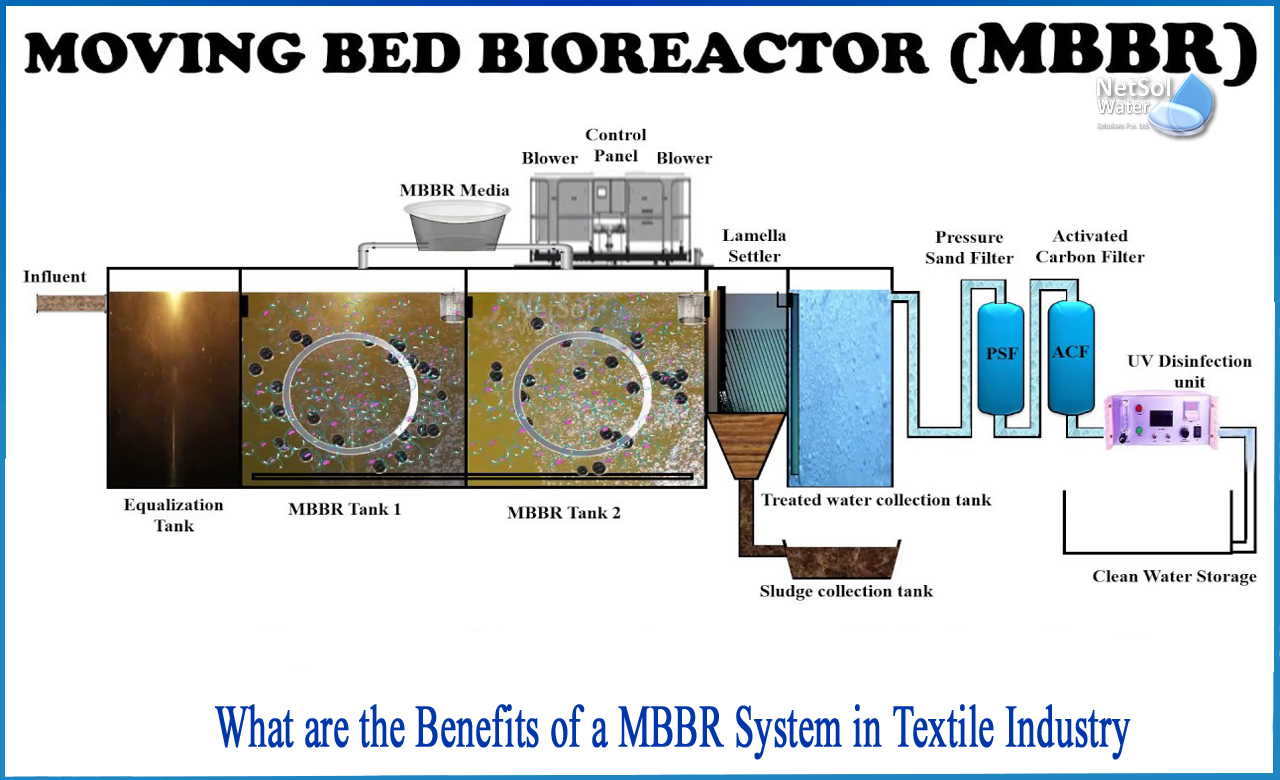

The moving bed biofilm reactor (MBBR) is a sort of wastewater treatment technology that is relatively new and crucial.

MBBR tank is made up of an aeration tank that looks a lot like a sludge tank but includes geometrically structured plastic. This substance adds to the surface area available for biofilm formation. The growing bacteria devour the organic materials in the effluent. Wastewater treatment plants that want to boost their operating capacity and efficiency without expanding their building footprint might consider MBBR. It's also beneficial for wastewater treatment plants that are subjected to heavy volume loads on a regular basis.

Wastewater solutions for textile factories with limited space

>Units for aerobic treatment: These are compact and can be placed in limited areas. Mechanical aerator oxygen diffuser systems powered by blowers are used in these units to supply oxygen into the wastewater column, where aerobic decomposition can occur.

>Fixed activated sludge units and media filters: These solutions are best for treatment facilities with lower flow rates, such as those with 1,000 to 5,000 gallons per day. Media filters are used in plants to lower the number of suspended solids in wastewater, which reduces the size of the sludge tank required. Because they can handle a large volume of concentrated waste materials, activated sludge units have a low land need.

>MBBR: Because MBBR systems can manage high concentrations of biosolids, the treatment tanks used to treat a high-volume flow do not need to be big. Because of this, they are a good choice for textile facilities with limited space.

What are the benefits of a MBBR system in textile industry?

1. Saves space: MBBR systems are excellent space savers. Because of their high organic load and hydraulic capacity, they can perform the same tasks as other types of aeration systems while taking up less area. As a result, MBBR systems are ideal options for textile manufacturers with limited space.

2. Toxic resistance: Because of the high biomass content, MBBR system is robust and can easily withstand environmental changes. MBBR system, for example, will not be harmed if harmful compounds are introduced into the wastewater system, which could ordinarily produce toxic shock. Because of this, MBBR is a good solution for textile wastewater treatment.

3. Ability to treat strong waste: MBBR system can manage particularly strong and concentrated forms of wastewater, such as chemical wastewater, due to the high concentration of suspended solids in the system. Because of this, MBBR systems are suited for textile wastewater treatment.

4. Improved nitrification: Nitrifiers grow slowly in comparison to other microorganisms, but MBBR system's textured plastic carriers provide a stable surface on which they can develop securely and steadily. MBBR provides enhanced nitrification inside the wastewater by promoting the growth of these nitrifiers, making it appropriate for wastewater with a high nitrogen content.

5. Efficiency: Because of the aeration system, the MBBR carriers are constantly bobbing in the wastewater. Because they are always moving, these carriers put their biofilm into contact with the wastewater on a regular basis. This feature contributes to a high level of mass and oxygen transfer efficiency, which aids in the wastewater treatment process's speed.

6. Low-maintenance: MBBR system, in particular, has this advantage over standard activated sludge systems. Managing traditional activated sludge can be a time-consuming and demanding operation. To keep the system functioning properly, the balance of food vs bacteria must be carefully regulated. There is no need for tedious sludge calibration with MBBR.

7. Cost-cutting: Managing activated sludge comes at a high price in terms of time, money, and resources. Traditional activated sludge systems require the sludge to be recycled, which incurs additional expenditures. Sludge recycling is not required with MBBR systems. As a result of this element, costs are reduced. Membrane bioreactors are more expensive than MBBR systems.

8. User-friendliness: MBBR systems are extremely user-friendly, particularly for plant operators who have never used one before. They are simple to operate due to their low maintenance requirements. The plant operator has fewer controls to monitor and calibrate because microorganisms handle most of the work.

9. Longevity: An MBBR system's biofilm carriers are carefully engineered to last a long time. This lengthy life expectancy improves the overall system's longevity.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.