Activated carbon, which can be broadly categorised into two types, mineral carbon and wood carbon, serves as the primary raw material for activated carbon filter cartridges. Among these, carbon from coal and carbon from coconut shells are more frequently employed.

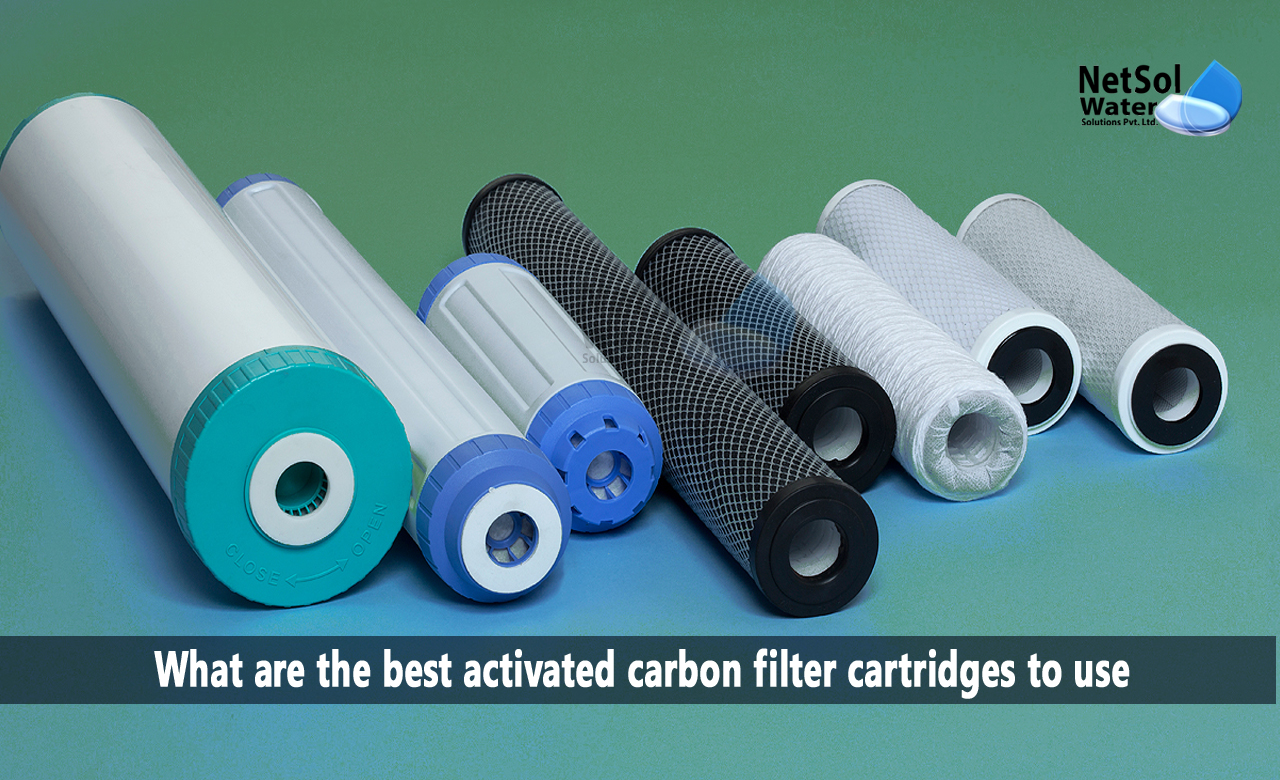

Extruded carbon block cartridges, sintered carbon block cartridges, granular activated carbon filters, and carbon impregnated cellulose filter cartridges, are a few examples of activated carbon filter cartridges. Let's examine the capabilities and potential uses for these activated carbon filter cartridges.

What are the best activated carbon filter cartridges to use?

1. Cartridges for Extruded Carbon Block Filters

Coconut shell or coal-based activated carbon is used to make the extruded carbon block filter cartridge. These raw materials are combined with an inorganic liquid binder, which is then put into a specific mould, crushed under high pressure, and dried after being expelled from the mould.

Extruded activated carbon cartridges are mostly used in food and beverage, drinking water, wine, etc. and have the primary purpose of absorbing odour, residual chlorine, and pigment.

2. Cartridges for Sintered Carbon Blocks

Activated carbon powder and polymer hot-melt pore-forming material are mixed together, poured into a specific mould, and sintered at a high temperature of 200–300°C, to create sintered activated carbon filter cartridges.

Because, the polymer bonding substance can create open micropores during the sintering process, the properties of activated carbon powder's high specific surface area are preserved. It is used mostly in drinking water, hospital water, food and beverages, clean water.

3. Filters with Granular Activated Carbon

The granular activated carbon filter is created by ultrasonic heat welding raw materials, such as coconut shell or coal-based activated carbon onto a plastic filter shell. There are no chemical additives added.

Multi-layer fibre non-woven fabric is installed at the water inlet and outflow of the filters, to stop carbon powder leakage. Granular activated carbon filters' primary job is to remove organic contaminants, chemical pesticides, residual chlorine, pigment, and off-putting odours from water. Drinking water, commercial water, home water, etc. are the principal uses for it.

4. Cellulose Filters with a carbon impregnation

The precision fibre filter membrane that first covers the inner frame, of the carbon impregnated cellulose filter cartridge is wrapped by fabric made of activated carbon fibre. The deep activated carbon fibre cloth of the outer layer of the filter cartridge can absorb odd smells, odours, organic pigments, etc., in addition to contaminants when the liquid passes through the filter cartridge. In general, printed circuit boards, surface treatment, electroplating solutions, coatings, etc. use carbon-impregnated cellulose filters.

Conclusion

Along with the previously stated regularly used activated carbon filter cartridges, other options include composite activated carbon filter cartridges, wrapped active carbon filter cartridges, pleated activated carbon filter cartridges, and cartridges loaded with silver.

he appropriate activated carbon filter element must be chosen when developing the activated carbon filtering system, in accordance with the liquid's composition, viscosity, temperature, and effluent requirements.

Get high-quality Activated carbon filters from us!

Netsol Water is a top producer of industrial and commercial water treatment plants and wastewater treatment plants. We provide different products to help you improve your water quality, including RO Plants, activated carbon filters, water softeners, etc.

All kinds of chemical, physical, and biological impurities can be effectively eliminated, by our water treatment systems. For further information or to make a product purchase, contact us at +91-9650608473 or drop a mail at enquiry@netsolwater.com