Every year, city, industry, and agricultural operations generate a large volume of wastewater. Natural water bodies receive the majority of various wastewater streams, resulting in increased nitrogen discharge, which can lead to eutrophication in natural aquatic environments, as well as a decline in shellfish habitat and aquatic plant life.

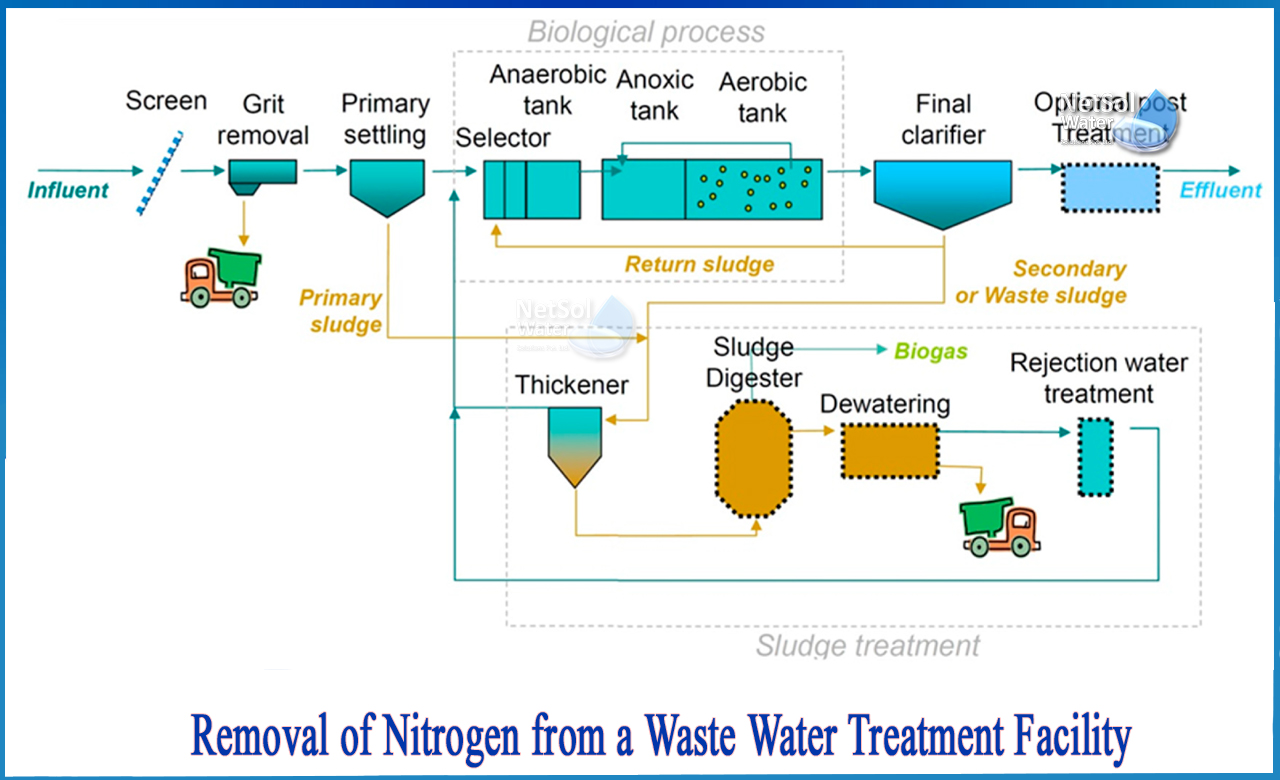

Biological (activated sludge) treatment is the most widely utilised nitrogen removal technology in wastewater treatment plants (WWTPs). In biological treatment, nitrogen is removed in two steps: nitrification and de-nitrification.

Nitrifiers, such as ammonia-oxidizing bacteria (AOB) and nitrite-oxidizing bacteria (NOB), convert total ammonia (free and un-ionized ammonia) to nitrate throughout this process. De-nitrification occurs in an anoxic environment when denitrifier’s convert nitrate and nitrite to nitrogen gas. Per gramme of total ammonia, 4.57 grammes of O2 are required to oxidise to nitrate.

How to remove Nitrogen in Waste Water treatment facility?

Mechanical aeration in WWTPs provides a huge amount of oxygen while costing 45–75 percent of the plant's total energy requirement. The aeration process has the potential to remove volatile chemicals. Furthermore, waste-activated sludge (WAS) is a significant byproduct of biological treatment. The quantity of WAS produced is proportional to the amount of wastewater processed. The activated sludge process produces around 70–100 kg dry WAS per million litres of wastewater treated. The volume of WAS is growing in tandem with the ongoing growth in wastewater output. Significant energy and a big geographical area are necessary to treat and dispose of WAS.

What are microalgae?

Microalgae are oxygen-releasing photosynthetic organisms with a basic cell that lacks roots, stalks, and leaves. Microalgae grow quickly, generate widely, and may treble their biomass in 24 hours. They may multiply exponentially in 3.5 hours. They are common in the nature and may flourish in practically any habitat as long as the necessary nutrients are there.

Some microalgae live on rocks, in soils, or in symbiotic partnerships with plants. Microalgae are most typically found in fresh and saltwater aquatic systems, as well as wastewater streams from a number of sources. Microalgae may create a variety of useful metabolites such as lipids, carbohydrates, and bioactive chemicals. In general, lipid content ranges from 20 to 50 percent of dry weight. The concentration might be as high as 90% depending on the kind of algae, such as Botryococcus (green algae).

The nutrient (protein rich) residue left after lipid extraction is suitable for feeding animals and fertilising crops. Many research on microalgae for biotechnology applications have been undertaken. Microalgae have previously been used in business for a variety of reasons, including the manufacture of supplements, food additives, and other bioactive substances for the cosmetic and pharmaceutical sectors. Microalgae operate as microscopic aeration devices in natural aquatic systems, producing oxygen for other microbes and acting as carbon dioxide sinks that fix CO2. Various than oxygen–carbon dioxide exchange, interactions between microalgae and bacteria involve other features, indicating the possibility of a microalgae–bacteria consortium system for wastewater treatment.

Conclusion:

Providing DO for nitrifiers in conventional nitrification processes in WWTPs typically needs expensive energy and cutting-edge equipment to generate very thin air bubbles. Microalgae, being a small photosynthetic cell, may work as an aeration device to deliver oxygen to bacteria. Using microalgae to clean wastewater offers a viable option to conserve energy while developing a long-term treatment procedure.

Microalgae–bacteria consortia systems have mostly been researched in manufactured and natural wastewater with low ammonia contents. However, investigations on high ammonia concentrations in wastewater, such as concentrate, are uncommon. To remove large quantities of ammonia from reject water, a high rate of oxygen synthesis is required.

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.