What is the role of evaporative condenser in water softening?

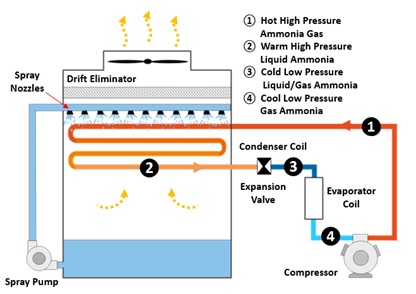

Evaporative condensers are mostly used for heat rejection in low temperature ammonia refrigeration application in cold storage and food processing units. They are often confused with standard cooling towers but there are some key differences between evaporative condensers and the cooling tower systems used in heating ventilation and air conditioning applications. Understanding these differences and the challenges they present is important for water treatment program success in any usage to fulfil the demand.

Both cooling towers and evaporative condensers reject heat by the process of evaporative cooling. As fresh makeup water is added to replace evaporation losses, the dissolved solid in the recirculating water gets enhanced. If the dissolved solids are allowed to over-concentrate, scale deposits will form and eventually decrease the efficacy.

In cooling tower systems, the cooling water is circulated starting from the basin through extensive piping to heat exchange equipment and returned to the top of the tower to be cooled again for the process. While as in an evaporative condenser, the cooling water is recirculating from the basin to the top of the unit to be sprayed over the condenser coil containing the refrigerant.

Plants possessing multiple evaporative condensers, a common sump design can greatly reduce the potential for upsets and improve control over the entire process. In a true common sump, water from the individual evaporative condensers drain directly into a remote sump with either individual or common recirculating pumps feeding the spray nozzles in each unit. When the spray pumps are off, all the water drains into the common sump leaving the outside basins dry.

Plants with multiple, standalone evaporative condensers can often be retrofitted with a forced common sump system to help simplify water treatment and improve control.

In a forced common sump system, a sump tank with a dedicated recirculating pump is used to force the water in the individual evaporative condensers to mix. This increases the water volume and eliminates the need to install chemical feed and control equipment on each evaporative condenser. It is important that forced common sump systems be properly designed, sized, and balanced to provide consistent mixing. Pre-fabricated forced common sump systems are available.

Depending upon the makeup water source, manufacturer water quality guidelines for passivation may be difficult, or impossible, to consistently maintain. Extreme caution with additional control measures is necessary when using acid or acid-based inhibitors for pH control

CRITICAL PARAMETERS

In evaporative condensers, good flow through the spray nozzles that distribute cooling water over the densely packed condenser tube bundle is critical for deposit control. If flow is inconsistent, uneven, or blocked, dry spots and bridging deposits will occur that can dramatically reduce refrigeration efficiencies and increase operational costs.

It is the owner’s responsibility to routinely inspect the spray nozzles and tube bundle with the pumps on for signs of dry spots, blockages, or missing nozzles. More frequent inspections may be required in response to seasonal issues related to plants and bugs. Once bridging deposits form, condenser tube bundles are nearly impossible to clean.

For such pre-treatment, water softeners can be installed.

Consult Netsol Water for more information!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturer, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.