- For Enquiry- 0120-2350053 || +91 9650608473 || +91 9650795306

- enquiry@netsolwater.com

If proper planning is done, the treated wastewater can be used in cooling towers. It can save up to 10-30% on water costs while switching from freshwater to wastewater. When treated wastewater, i.e., recycled water, is used for cooling towers, it secures a drought-proof water supply. The use of recycled water is helpful because it can protect the potential future growth of water supply and save us from the shortage of water both in the present and future. Recycled water enhances the overall water efficiency and helps in building green water goals.

So, let us understand how this cooling tower process works and what chemicals should be used to make the process efficient.

When the water flows through the cooling tower, it is exposed to the air. The air is pulled through the building by an electric-driven motor fan. When this water and air get exposed to each other, a small amount of water evaporates. In turn, it creates a cooling action. Chlorine dioxide can be used as a disinfectant to destroy microorganisms and prevent recurring growth.

The pH of the water should be between 6.5-9.0. It is an ideal pH range for circulating the water. This range is preferred because the corrosive conditions will not arise in the cooling tower if the pH is within these limits. The alkaline conditions should be appropriately monitored in the circulating water system.

Now, we discussed that the pH of the circulating water should be maintained. Has anyone ever wondered what causes high pH in cooling towers? When circulating water aerates each time, it passes through the cooling tower. This process goes on, and it reduces the carbon dioxide concentration in the water that causes pH to rise.

Using recycling water manages the management of corrosion that is essential to keep piping and equipment in good operating condition. It thereby extends the life of a cooling tower and hence is a cost-efficient process.

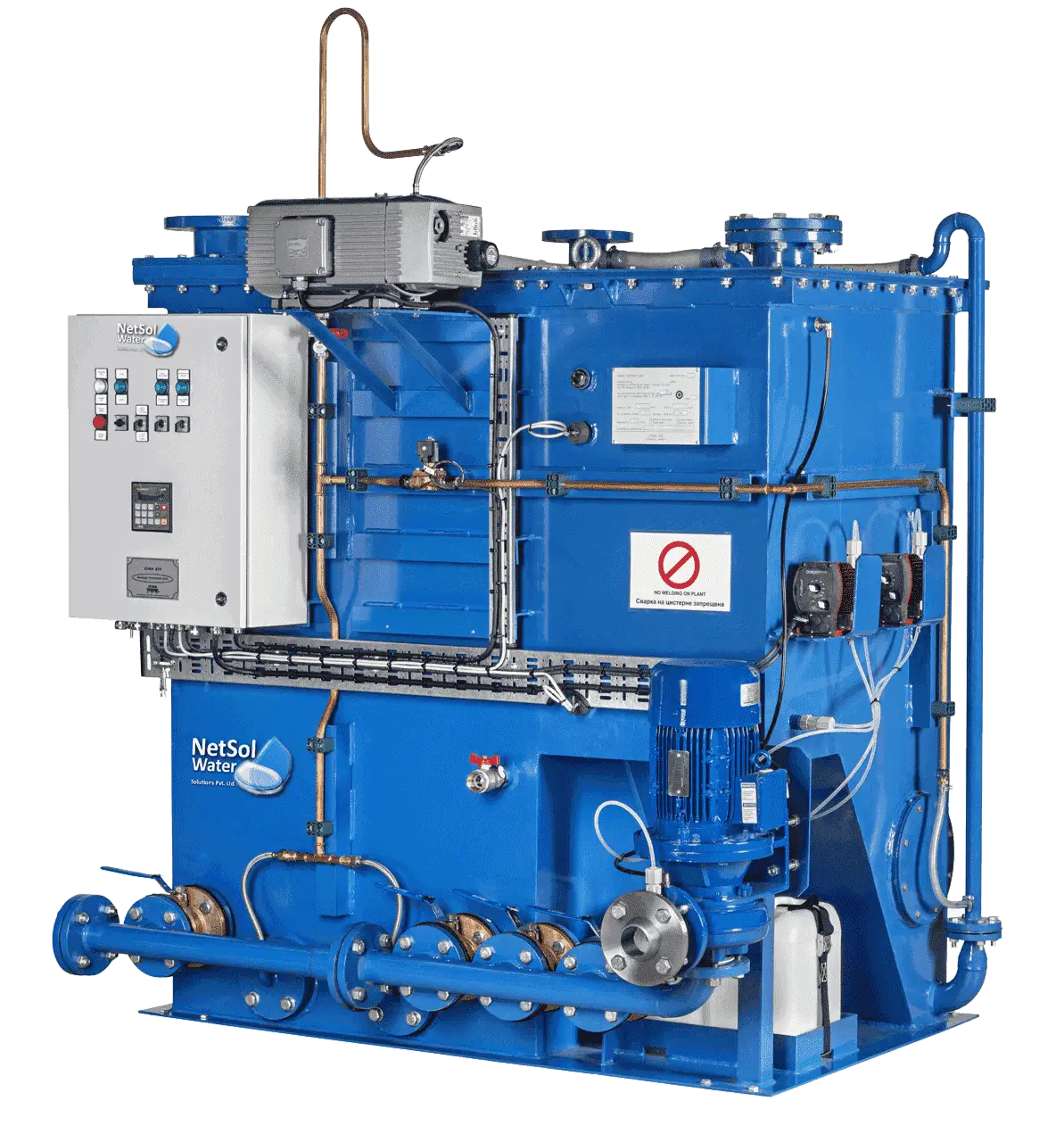

Membrane BioReactor (MBR) is the best STP technology to be used for cooling towers. It is a process that combines the use of micro-filtration and an activated sludge process. This process is used in place of a secondary sedimentation tank and sand filter used for tertiary treatment in conventional activated sludge processing.

This technology provides features such as compactness, easy to use, and high-quality water. The water generated can be reused, and it is beneficial in cooling towers. In addition to this, the advanced treatment of nitrogen and phosphorus removal can also be achieved by anoxic and aerobic treatment. We all know how much therapy of chemicals like nitrogen and phosphorus helps cool towers. We must promote and offer the best to our customers and environment. Use this technology and help us in saving water resources.

If you have any doubts, please feel free to reach us. Contact us to discuss your requirements. We can be reached at 9650608473 and 9650795306, or feel free to leave your query at enquiry@netsolwater.com.

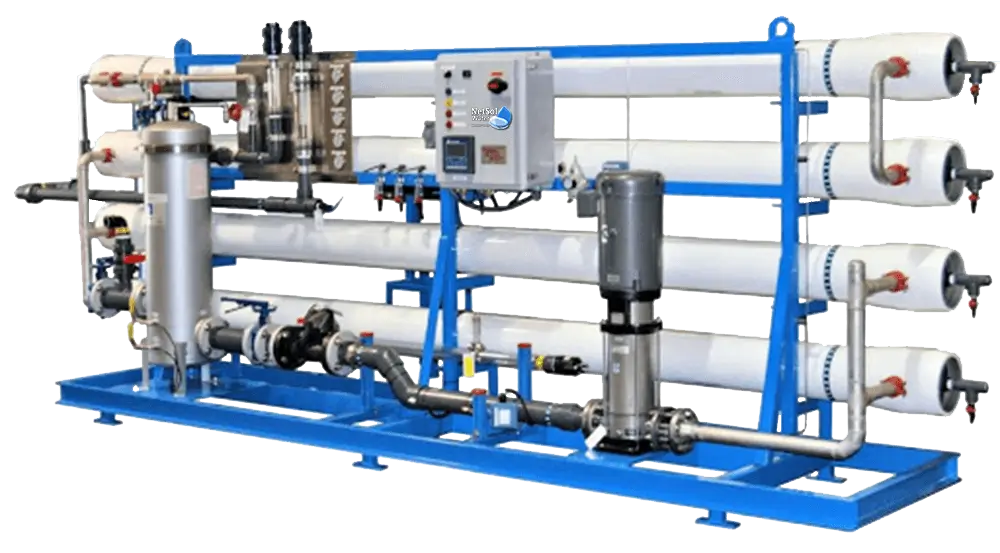

Netsol Water Solution is a Greater Noida, Uttar Pradesh, India based manufacturer, seller, and supplier of waste and wastewater treatment plant. With the latest and leading technology, we are the leader Commercial RO Plant Manufacturer, Industrial RO Manufacturer, Sewage Treatment Plant Manufacturer, Effluent Treatment Plant.