What are lift stations used for?

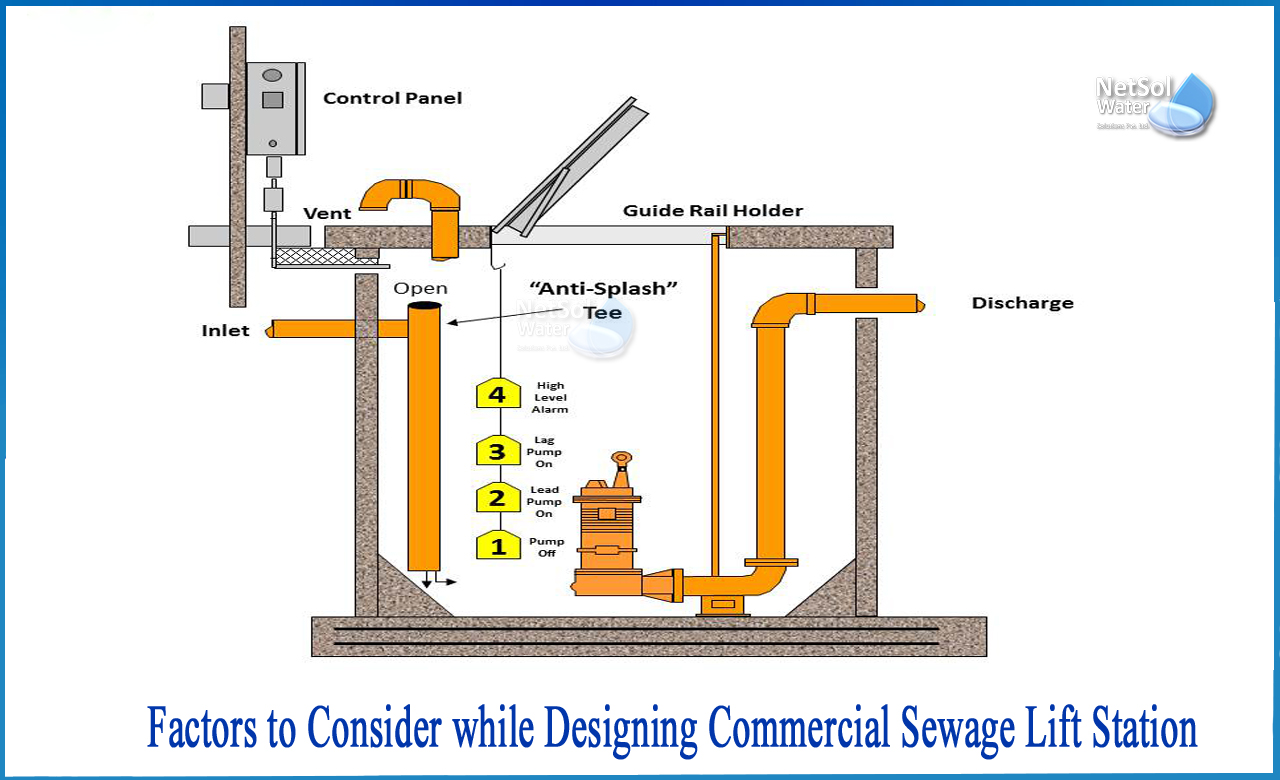

Lift stations are used to pump wastewater to higher elevations in order to allow transport by gravity flow. Sewage is fed into sealed underground pit, commonly known as a wet well. As the wastewater level rises to a predetermined point, a pump will start to lift the sewage upward through a pressurized pipe system from where it gets discharged into a gravity manhole again. From here the cycle starts all over again until the sewage reaches its final point of destination which is usually a treatment plant.

Need for sewage lift stations

Lift stations, are designed to handle raw sewage that is fed from underground gravity pipelines. They are used to lift wastewater to higher elevations.

In general, the need for sewage lift stations arises when:

· The existing topography allowing sewage to flow by gravity have high construction costs. The sewage is elevated and then conveyed by gravity.

· Basementfloors are too low to discharge sewage to the main sewer by gravity.

· Sewage line is conveyed over a ridge.

· The sewage must be raised to get the required head for gravity flow through a treatment plant.

· Discharge outlets are at lower level of the receiving body of water.

· An existing gravity system is not available. A lifting station will enable development and growth in accordance with the applicable community plan.

Factors to be considered while designing commercial sewage lift stations

1. Location of the lift station:Suitable location of pumping station requires a detailed study of the area to be served to ensure that the entire area can be drained adequately. The site for pumping station should be satisfactory. The location of pumping station should be so easily accessible under all weather conditions.

2. Selection of Power Source: The power source will be the local electricity grid. A feeder from the nearby substation can be considered and in large pumping stations, two such independent dedicated feeders from two different substations are recommended.

3. Design Discharge Level: The static lift is decided by the level of water surface in the receiving structure. Friction losses and free-fall at receiving chamber needs to be added to this. This has to be increased by raising the discharge elevation by means of a raised delivery line ending up in a goose-neck before dropping the flow into the receiving chamber such that the hydraulic grade line shifts upwards in its terminal end.

4. Design Suction Water Level: The suction level should be below the invert of the incoming sewer to facilitate air passage through the sewer. A preferable drop of 50 cm to 100 cm below the invert of the incoming sewer is desirable to prevent problems of choking of sediments in sewers due to stagnations.

5. System head:Head loss occurs when there is friction in pipes or components like the elbows. Friction can make it difficult for a pump to cool down, resulting in unnecessary wear and tear. To avoid head loss, plan for the system head curve. Make the pipe length and elbows small, it can lead to head loss. Or consider the vertical lift that the wastewater must be able to travel, to keep wear and tear to a minimum and reduce the need for unexpected maintenance.

6. Wet well:All of the commercial wastewater may collect in a covered wet well. Minimum number of wet wells irrespective of the volume of sewage to be pumped out, shall be two. The structures shall preferably be circular in plan to facilitate simpler and economical construction, besides removing accumulated grit from one of the wells at a time without interrupting the pumping out.

How can Netsol Water help you in this?

Netsol water is one of the leading water and wastewater treatment company in India offering projects and services in the field of water and wastewater treatment plant manufacturing and supplying machines like compact sewage treatment plants which not only turns your waste water into usable water but also acts as a savior of Mother earth and its precious resource “water”.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.