What are the different types of anaerobic digester?

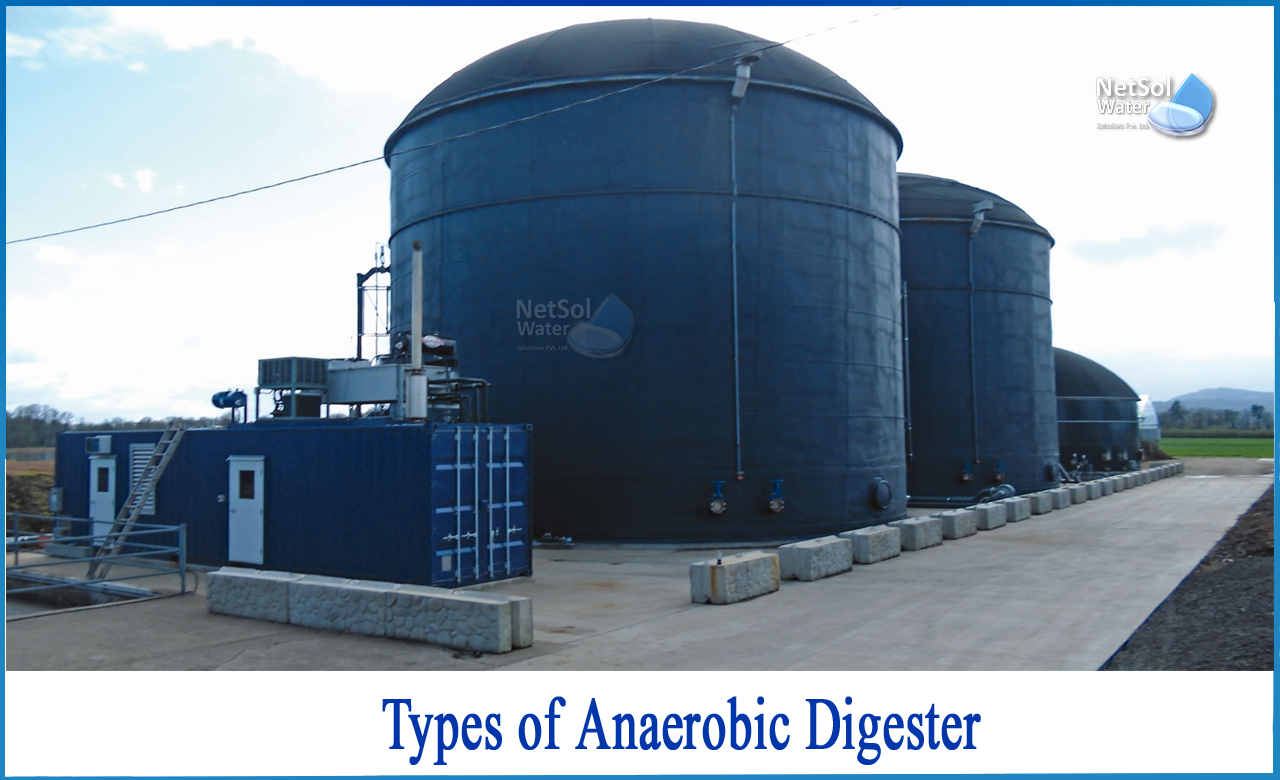

Anaerobic digester are systems and processes that use anaerobic digestion for biowaste treatment, animal manure treatment, sewage treatment, and biogas generation.

Anaerobic digesters are classified based on numerous factors, including whether the biomass is linked to a surface ("attached growth") or can freely mix with the reactor liquid ("suspended growth"), the organic loading rate, and whether they are centralised or decentralised.

Wet-type anaerobic digestion, in which biomass and water are mixed in equal volumes to generate a slurry with a total solid’s percentage of around 10-15%, is used in the majority of anaerobic digesters around the world.

The following is a partial list of types of anaerobic digesters

1: Anaerobic migrating blanket reactor (AMBR)

After completing a parallel investigation using upflow anaerobic sludge blanket (UASB) and anaerobic sequencing batch reactor (ASBR) procedures, the anaerobic migrating blanket reactor (AMBR) was created. No separate pre-acidification is required for the AMBR due to high mixing intensities and the washing away of acidogenic bacteria.

2: Anaerobic Digester in a Batch System

Anaerobic sequencing batch reactors (ASBR) are a type of batch system.

It is a batch-fed, batch-decanted suspended growth system that operates in four stages: feed, react, settle, and decant. It consists of a single tank in which all events occur, and because a major portion of the cycle time is spent separating the biomass from the treated wastewater, the reactor volume need is greater than for continuous flow systems. However, this drawback is more than outweighed by its simplicity (no extra biomass settling stage or solids recycle is required) and the absence of feed short-circuiting, which is common in continuous flow systems.

3: Continuous stirred-tank reactor

The continuous stirred-tank reactor (CSTR), also known as a vat- or backmix reactor, a mixed flow reactor (MFR), or a continuous-flow stirred-tank reactor (CFSTR), is a typical chemical reactor model in chemical engineering and environmental engineering.

CSTR is a model that is frequently used to estimate the critical unit operating variables when employing a continuous agitated-tank reactor to achieve a certain output. The mathematical model is applicable to all fluids, including liquids, gases, and slurries.

CSTR's behaviour is frequently approximated or modelled by the behaviour of an ideal CSTR, which implies complete mixing. When reagent enters a properly mixed reactor, it is instantly and uniformly mixed throughout the reactor. As a result, the output composition is the same as the composition of the material within the reactor, which varies with residence time and reaction rate.

The CSTR, which is the polar opposite of a plug flow reactor, is the optimal limit of total mixing in reactor design (PFR). In actuality, no reactor behaves optimally, but rather midway between the mixing limitations of an ideal CSTR and PFR.

4: Digestion of expanded granular sludge beds

An extended granular sludge bed (EGSB) reactor is a version of the anaerobic wastewater treatment idea of upflow anaerobic sludge blanket digesting (UASB). The differentiating feature is that the wastewater passing through the sludge bed has a quicker rate of upward flow velocity. The enhanced flow allows for partial expansion (fluidisation) of the granular sludge bed, boosting wastewater-sludge interaction and promoting sludge bed segregation of tiny inactive suspended particles. The higher flow velocity is achieved by either using tall reactors or including an effluent recycling system (or both).

The EGSB design is suitable for low strength soluble wastewaters (less than 1 to 2 g soluble COD/l) or wastewaters containing inert or weakly biodegradable suspended particles that should not build on the sludge bed.

For water, wastewater or sludge treatment, Netsol Water Solutions offer a complete spectrum of wastewater treatment products. Our engineers would gladly collaborate with your team to create the right design that meets your budget and objectives.\

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.