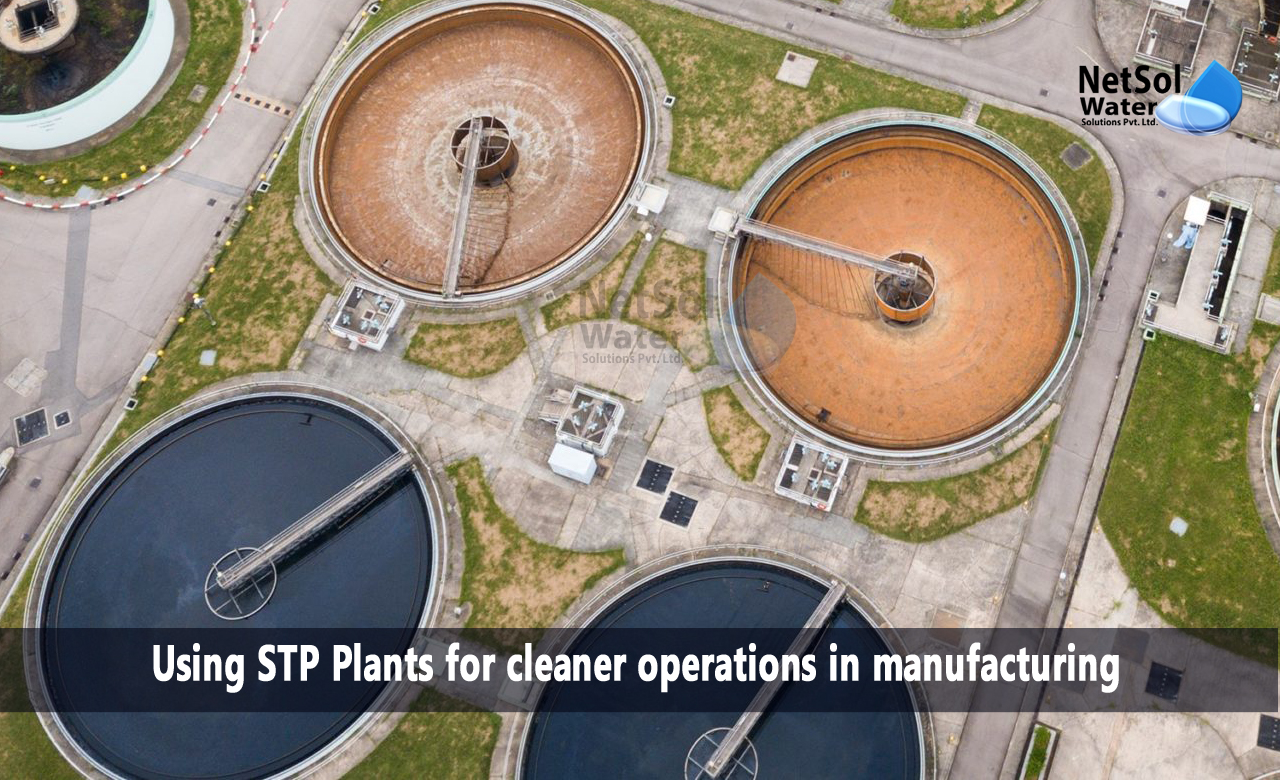

How to use STP Plants for cleaner operations in manufacturing?

In an era where sustainability is paramount, industries are striving to make their operations cleaner and more environmentally friendly. One vital player in this transformation is the partnership between manufacturing facilities and sewage treatment plants (STPs). By leveraging the capabilities of STPs, manufacturers can significantly reduce their environmental impact, improve operational efficiency, and contribute to a brighter future for all.

In this blog, we will explore How to use STP Plants for cleaner operations in manufacturing.

1- Effective Wastewater Treatment

Sewage treatment plants are experts in treating and purifying wastewater, including the discharge from manufacturing processes. By collaborating with STPs, manufacturers can ensure that their wastewater undergoes proper treatment to remove harmful substances, contaminants, and pollutants. This commitment to responsible wastewater management reduces the impact on local water bodies, preserves ecosystems, and safeguards public health. By entrusting their wastewater to STPs, manufacturers can focus on their core operations, knowing that their environmental obligations are being met effectively.

2- Environmental Compliance and Regulatory Adherence

Stringent environmental regulations and compliance standards are becoming increasingly prevalent across the globe. Manufacturers face the challenge of meeting these requirements while maintaining efficient operations. Partnering with sewage treatment plants provides manufacturers with the expertise and infrastructure necessary to ensure compliance with regulatory guidelines. STPs possess in-depth knowledge of local regulations and can guide manufacturers in implementing sustainable practices, avoiding penalties, and maintaining a positive reputation.

3- Resource Recovery and Recycling

Sewage treatment plants offer a wealth of opportunities for resource recovery and recycling. Wastewater contains valuable resources such as organic matter, nutrients, and energy. Through advanced treatment processes, STPs can extract and repurpose these resources. For instance, organic matter can be converted into biogas through anaerobic digestion, providing a renewable energy source for manufacturers. Nutrient-rich sludge can be transformed into fertilizers, reducing the need for synthetic alternatives and closing the loop in agricultural supply chains. By collaborating with STPs, manufacturers can embrace circular economy principles, minimize waste, and unlock the value hidden in their wastewater.

4- Water Conservation and Efficiency

Water scarcity is a global concern, and responsible water management is crucial for sustainable manufacturing. Sewage treatment plants offer an opportunity for manufacturers to access reclaimed water for non-potable applications. By treating and reusing wastewater, manufacturers can significantly reduce their freshwater consumption, preserving this precious resource for essential needs. Utilizing reclaimed water for processes such as cooling, cleaning, or irrigation not only reduces operational costs but also demonstrates a commitment to water conservation and environmental stewardship.

5- Enhanced Sustainability Performance

Collaborating with sewage treatment plants contributes to a manufacturer's overall sustainability performance. By incorporating STPs into their operations, manufacturers can showcase their commitment to sustainable practices and responsible resource management. This commitment enhances their reputation among customers, investors, and other stakeholders, leading to increased brand value and market competitiveness. Manufacturers that prioritize sustainability gain a competitive advantage by aligning their operations with the values and expectations of a growing eco-conscious consumer base.

Challenges and the Way Forward

While the benefits of partnering with sewage treatment plants are clear, several challenges need to be addressed. These challenges include technological constraints, financial considerations, infrastructure compatibility, and fostering effective collaborations between manufacturers and STPs. Overcoming these hurdles requires investment in research and innovation, policy support from governments, and the establishment of robust partnerships between stakeholders.

Conclusion

Sewage treatment plants are instrumental in driving cleaner operations and a brighter future for the manufacturing industry. By collaborating with STPs, manufacturers can effectively treat wastewater, ensure compliance with environmental regulations, recover valuable resources, conserve water, and enhance their overall sustainability performance. The partnership between manufacturers and sewage treatment plants is a powerful catalyst for positive environmental change, paving the way for a more sustainable and prosperous future.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.