What is Single pass and Double pass RO systems?

Single-pass and double-pass RO systems are the most prevalent configurations. One distinction is that treated water is sent over a membrane twice in a double pass system. Additionally, compared to a single-pass system, double-pass RO has better percent recovery and GFD rates.

Single pass vs. Double pass RO systems

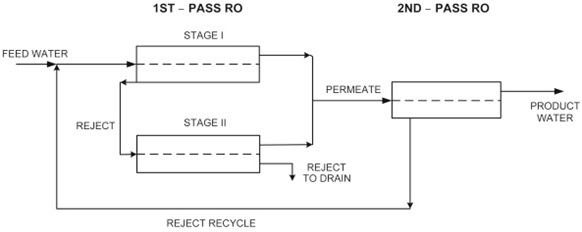

Consider a pass as an independent RO system. In light of this, a double pass RO system differs from a single pass RO system in a way that the permeate from the first pass serves as the feed water for the second pass (or second RO), resulting in a permeate that is of a considerably higher quality because it has basically gone through two RO systems.

Advantages of Double-pass RO Systems

1: A double pass RO system is employed to reduce water waste. Any water that would normally be disposed of as wastewater is re-circulated via the semi-permeable membrane by using a twofold pass technique. On a single pass system, there is often 20 to 25% water waste. When a double pass system is employed, this falls just to 5%. A double pass system would be especially helpful in the industrial setting where businesses must pay for both the water that enters the operation and the wastewater that exits.

2: A double pass RO system not only creates a permeate of considerably superior quality, but it also offers the chance to remove carbon dioxide gas from the permeate by introducing caustic between the first and second pass. When there are mixed-bed ion exchange resin beds following the RO, CO2 is not desired.

The first pass permeate water's pH can be raised by adding caustic, which also converts CO2 to bicarbonate (HCO3-) and carbonate (CO3-2) for better rejection by the RO membranes in the second pass. Because injecting caustic and producing carbonate in the presence of cations like calcium will scale the RO membranes, this cannot be done with a single pass RO.

Conclusion

Because it employs a technique called cross filtration, a reverse osmosis system differs from other filtration techniques. The standard method of filtration used by other filtration techniques involves molecules passing through a membrane and gathering there until the membrane is used up. With RO system, water flows through the system in a turbulent manner that prevents pollutants from accumulating on the membrane. Pure water and contaminants both pass through the filter media, which separates the water into outlets for pure water and wastewater.

Depending on the quality of your feed water and your product requirements, Netsol Water will design the entire reverse osmosis water treatment system both for your commercial and industrial use. When necessary, passes and stages will be implemented. Utilizing RO technology and integrating it with the appropriate pre- and post-treatment, Netsol offers comprehensive and sustainable solutions.

Our benefits include

· Engineered and specially created solutions for unusual problems.

· Design, engineering, manufacture, automation, installation, maintenance, service and training.

· Modern techniques for the efficient treatment, recycling, reuse and disposal of water and wastewater.

Best on-site service and support as well as online assistance.