How to Optimize Coagulation and Flocculation in Water Treatment?

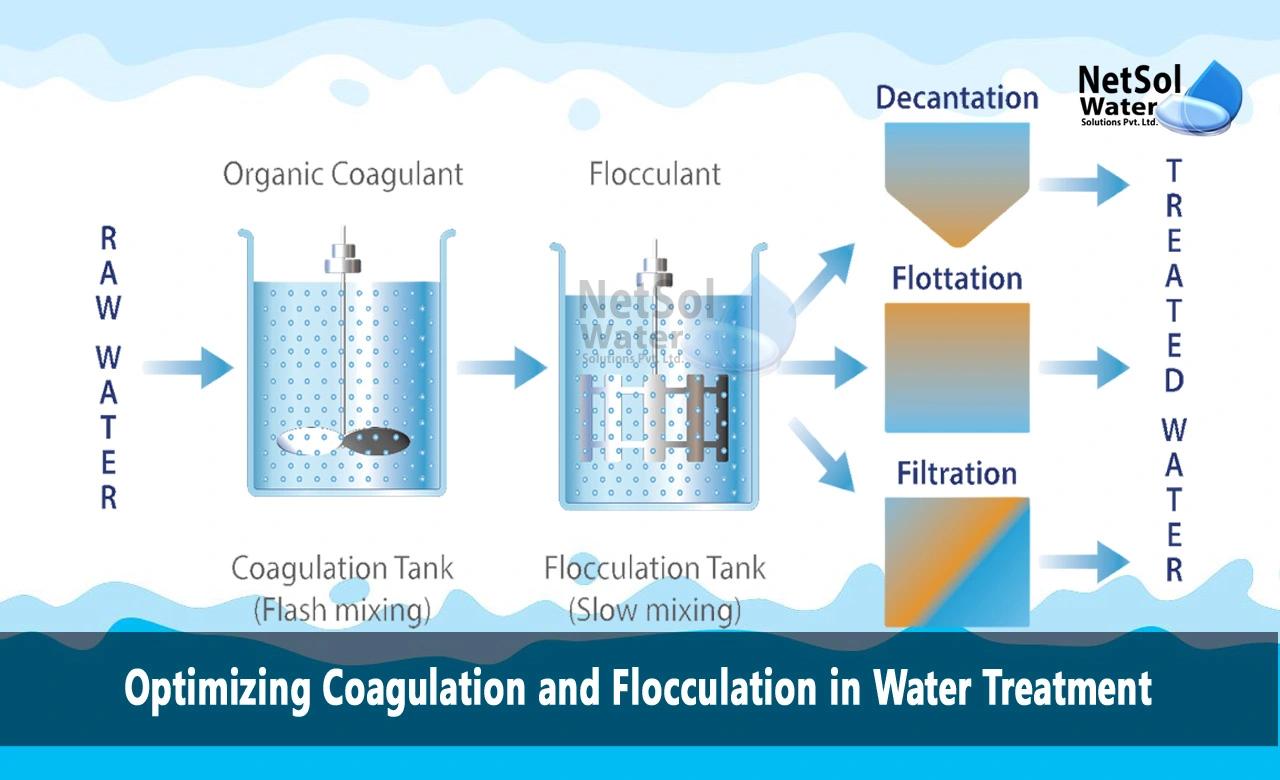

Coagulation and flocculation are critical pretreatment steps in surface water purification. Promoting particle agglomeration using chemical additives facilitates contaminant removal through subsequent clarification and filtration. However, suboptimal coagulant selection, dosing control issues, poor flocculation conditions, and lack of process integration diminish treatment performance. Optimising coagulation and flocculation through improved monitoring, chemical selection, and floc management increases treatment capacity and efficiency.

Key Process Control Parameters

Coagulation effectiveness relies on chemistry factors including water pH, alkalinity, natural organic matter levels, and temperature—alongside consistent coagulant dosing matched to raw water quality variation. Meanwhile, flocculation requires careful attention to energy input regulating floc formation and growth. Intensified monitoring via streaming current/zeta potential analysers, spectral absorption, turbidity fluctuation, and particle counting allows dynamic modelling, diagnosing, and refining process adjustments in response to source water changes.

Advanced Coagulant Formulations

Typical metal salt coagulants require supplementation with pH adjustment chemicals while producing large hazardous sludge volumes. Emerging products utilising organic polymers alone or with metal complexing avoid acids/bases for pH regulation while reducing residual generation. Coagulant blending also helps respond to challenging conditions like cold water temperatures or high dissolved organics loads. New speciality coagulants also aid in removing trace emerging contaminants (e.g., PFAS). Advanced coagulant selection, blending, and dosing optimisation maintain treatment efficiency across wider raw water condition swings.

Hydrodynamic Flocculation Technology

Floc blanket clarification relies on precise particle collision and consolidation regulation. At the same time, hydraulic flocculation targeting allows shorter detention for considerable floc growth at lower energy inputs. New integrated flocculation systems precisely model growth kinetics to determine stage-wise mixing energy for ideal floc sizes. These account for changing attributes via online monitoring to balance clarifier performance with energy conservation for greater productivity and cost savings—enabling higher surface water treatment capacity without facility expansion.

Netsol Water’s High-Rate Clarification Technology

Rising consumer demand amidst source water deterioration requires balancing treatment plant productivity, reliability, and affordability. Netsol Water combines data-driven variable coagulation optimisation with Upflow Compressible Blanket Clarification technology, maximizing floc capture in the smallest footprints. Auto-chemical selection, dosing, flash mixing, and multi-stage flocculation systems adapt to raw water variation for consistent clarified water quality up to 20 gpm/sq. ft.—double the typical clarifier rate. Combining high-rate separation at a lower cost with intelligent coagulant control maintains downstream filter performance despite challenging conditions.

Conclusion

Optimising coagulation and flocculation performance through smarter process controls, advanced chemistry options, and purpose-driven separation system design provides the foundation for affordable, sustainable surface water treatment amidst deteriorating source water quality and rising consumer demand. Harnessing real-time sensor data, predictive analytics, customisable coagulant formulations, and high-rate clarifiers enables resilience and productivity advances that are not possible in outdated facilities dependent only on fixed conventional steps.

Specifically, intelligence-enhanced coagulation/flocculation systems deliver higher capacity and consistent standards compliance across wider raw water condition swings—sustaining communities rather than restricting growth and tightening restrictions during every drought or wildfire crisis. More efficient separation reduces chemical consumption, sludge generation, and filtration requirements for lower operating costs. Adaptability is critical with rising extreme weather and water quality threats. Netsol’s clarification innovations provide the needed intelligence-optimized, high-performance platform suitable for securing community water supplies even as challenges compound. Smarter coag/flocc ultimately helps water providers to overcome any emerging obstacle reliably.

Do you need an advice or assistance on selecting the best water and wastewater treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473 Or write us at enquiry@netsolwater.com