What is Coagulation & flocculation processes in waste water treatment?

Dissolved and suspended particles are present in both groundwater and surface water. To separate the suspended solids from the water, coagulation and flocculation are used. The source, charge, particle size, shape, and density of suspended particles vary. These factors influence the proper application of coagulation and flocculation. Suspended solids in water have a negative charge, and because they have the same surface charge, they repel each other when they come into contact. As a result, unless proper coagulation and flocculation are used, suspended solids will remain in suspension and will not clump together and settle out of the water.

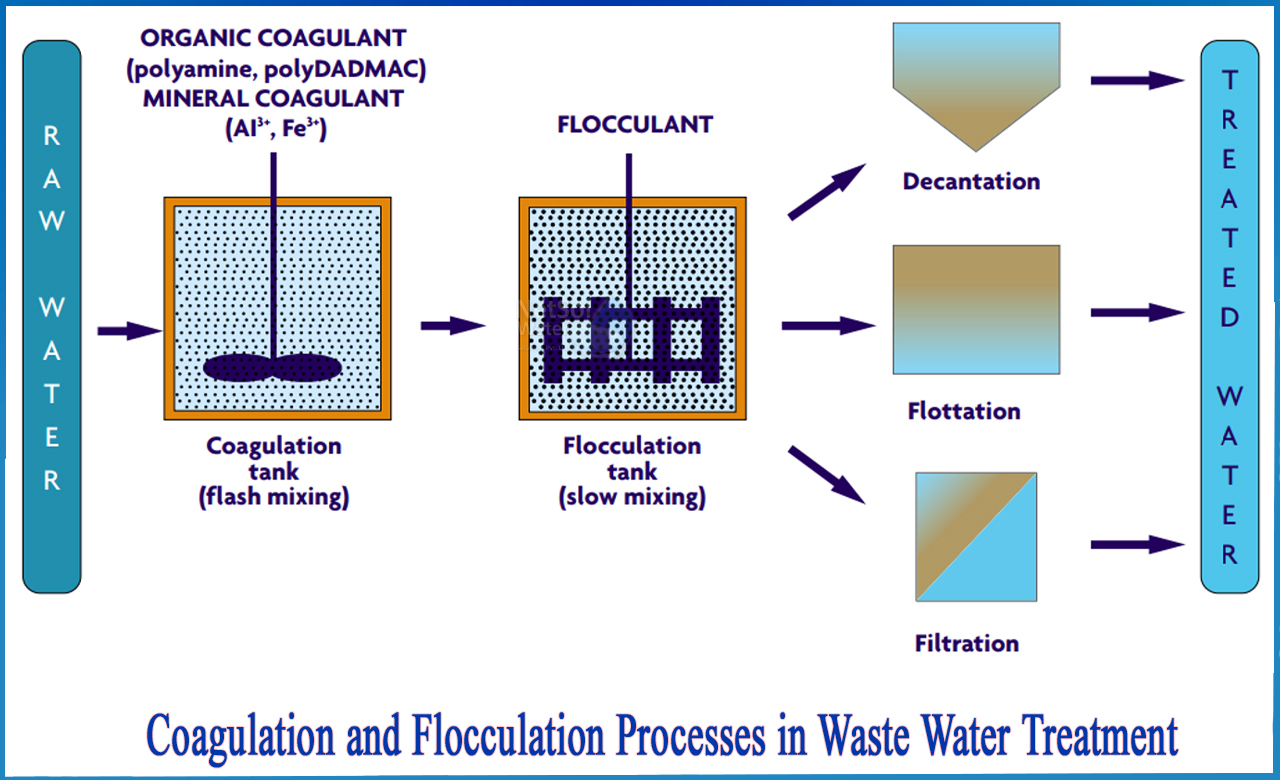

Coagulation and flocculation takes place in stages, allowing particle collision and floc growth. Sedimentation takes place after that. If the coagulation step is not completed, the flocculation step will be unsuccessful, and if the flocculation step is not completed, the sedimentation step will be unsuccessful.

Coagulation in Wastewater Treatment

The first step in chemical wastewater treatment is coagulation. Most of us learned about coagulation in anatomy class. It's what happens when our blood combines with oxygen, resulting in a scab or a blood clot. The same holds for wastewater treatment.

A harmless chemical, such as alum, is used in coagulation treatment to cause all of the particles to emit a positive charge and thus clump together, making them easier to filter. Coagulation is particularly effective at removing chemical phosphorus from water. Nonetheless, coagulation water treatment is not a novel process. Over mixing has no effect on coagulation, but inadequate mixing leaves this step incomplete. The rapid-mix chamber typically has a contact time of 1 to 3 minutes.

Flocculation in Wastewater treatment

In wastewater treatment, flocculation and coagulation work in tandem. After coagulation has clumped the waste particles together, flocculating agents in wastewater treatment are used to remove the clumps. Flocculants are polymers that cause destabilized clumps of particles to agglomerate and drop out of the solution, removing them from the filtered water. They can be lightweight, medium weight, or heavy weight. The weight used is determined by the type of particle.

Design intervals for flocculation range from 15 to 20 minutes to an hour or more, and mixing velocity and mix energy must be carefully monitored. As floc size increases, mixing velocity and energy are typically reduced to prevent floc from tearing apart or shearing. After being torn apart, flocs are difficult to reform to their optimal size and strength. In flocculation, the amount of control available to the operator is highly dependent on the type and design of the equipment.

Coagulation, Flocculation, and Sedimentation work together

Some designs combine coagulation, flocculation, and sedimentation (either up flow solids contact units or sludge blanket units). To improve floc formation and make the most of treatment chemicals, most up flow solids contact units recirculate previously formed floes. Sludge blanket units propel newly formed flocs upward through a suspended floc bed. In both styles of units, the cross-sectional surface of the basin increases from bottom to top, causing water flow to slow as it rises and allowing floc to settle out.

On average, combination units use faster rise rates and shorter detention times than conventional treatment. Based on these design concepts, a slew of manufacturers sell proprietary units. These units are smaller and require less space for plant placement. Prior to design, an on-site pilot plant evaluation by a qualified engineer familiar with the water quality is recommended.

Contact Netsol Water for further information.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.