Large manufacturing plants now have large production lines that need to take over the tasks of the air control system within the unit. Without it, it would be difficult for both workers and machines to work efficiently and uninterrupted.

What is an industrial Air Blower?

An industrial Blower drives the air. The wheels of an industrial Blower draws air into the inlet of the Blower housing, and the axial Blower blows air in the same axial direction. Industrial Blowers are used for cooling industrial equipment, general ventilation of rooms and factories, extraction of industrial processes, food processing, drying of ink in cans and bottles, and many other industrial applications.

Netsol Water Solution is a well-known manufacturer of a wide range of industrial Blowers. These industrial Blowers are highly valued by our customers for their robust construction, high efficiency, long life, corrosion resistance and durability.

We have a dedicated team of professionals who are constantly working to improve the design and function of industrial air control Blowers, which play an unavoidable role in large industries. We have state-of-the-art manufacturing facilities equipped with the latest machines for manufacturing industrial Blowers to industrial quality standards.

Design of Air blowers:

The two most important variables used in system design are pressure and airflow.

For impeller-based centrifugal Blowers and regenerative Blowers, there is an inverse relationship between air flow and Blower outlet pressure. This means that an increase in system back pressure at the blower outlet leads to a decrease in air flow.

Blower outlet pressure is the cumulative pressure created by the connected elements resisting the flow. Factors such as hose or pipe length and path, nozzles and in-line heaters all contribute to the back pressure that the blower must overcome.

The greater the back pressure on the Blower, the less flow the Blower can supply. At the far end, there is no air flow when the Blower outlet is completely blocked. If the blower is released directly into the atmosphere (that is, if no system elements are connected), the blower can achieve the maximum rated flow rate.

Blower manufacturers provide blower curves for each blower type that represent the pressure-flow relationship for a particular model.

How to read and interpret the Blower curve?

Choosing the right blower is a basic step in developing a functional and efficient system!

Most Blower manufacturers use similar types of specifications to describe the functionality of their Blowers.

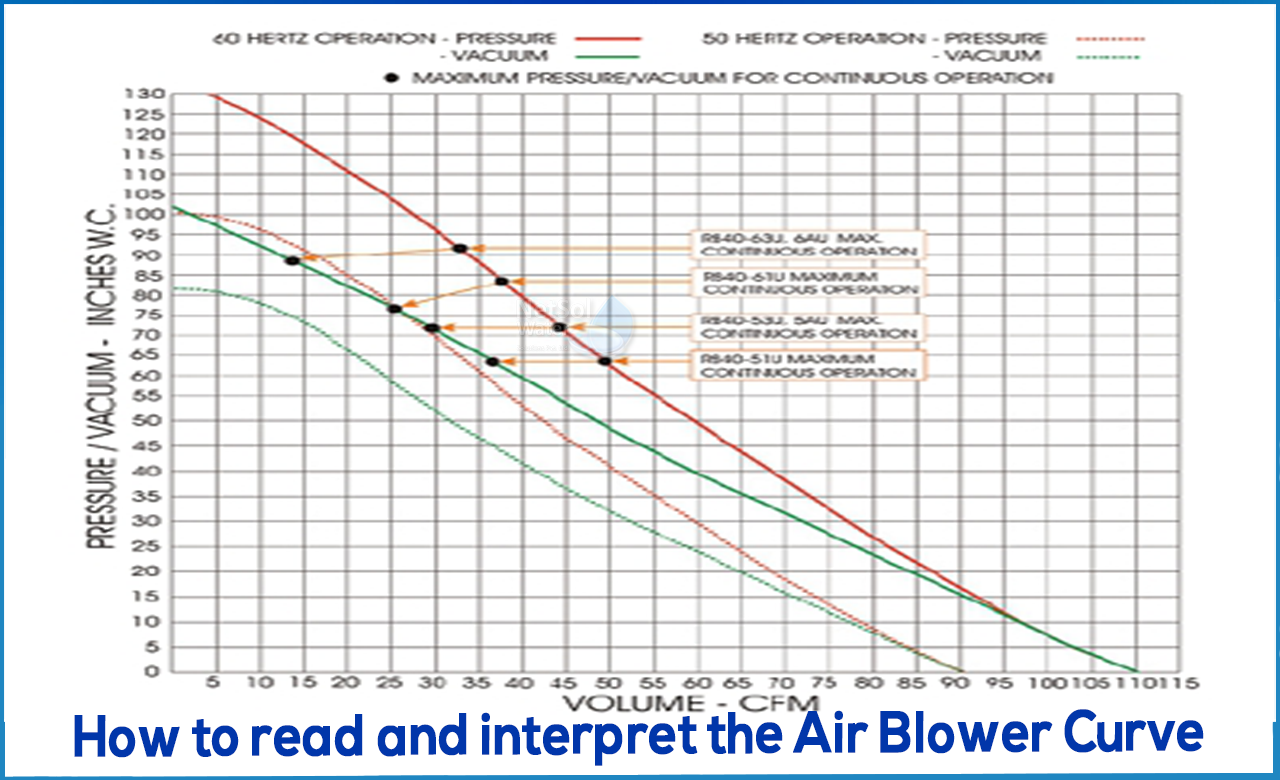

In the above example, there are several curves at 50Hz and 60Hz, respectively.

Blower speed increases with increasing operating frequency. This also improves Blower performance. Therefore, the 60Hz Blower curve is shifted to the right of the figure than the 50Hz curve.

The Blower curve shows the characteristics of the Blower over the entire operating range. However, continuous operation of the blower above maximum pressure will significantly limit its useful life. For this reason, manufacturers specify pressure limits that allow the blower to operate safely for extended periods of time.

In the above example, the manufacturer has many Blowers with the same Blower curve but different continuous operating pressure capabilities.

Blower Curve

Example: On the above curve if the desired operating pressure is around 50 to 60 inches of water, we can only expect approximately 50 CFM of flow.

For more information, Netsol Water (+91-9650608473) is just a call away!

The author of the blog is associated with Netsol Water Solutions, which is into the manufacturing Effluent Treatment Plant, MBBR Sewage Treatment Plant, and Water Treatment Plants.