- For Enquiry- 0120-2350053 || +91 9650608473 || +91 9650795306

- enquiry@netsolwater.com

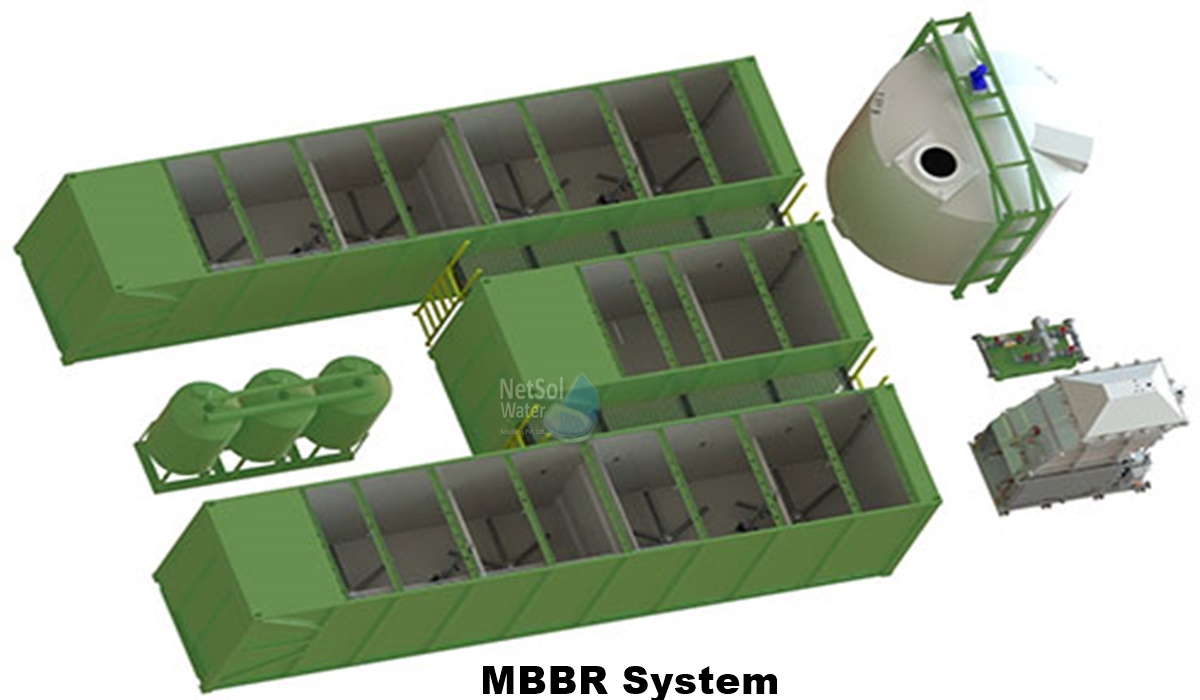

MBBR is commonly known as Moving Bed Biofilm Reactor,is a type of wastewater treatment process that was first invented by Prof. Hallvard Ødegaard at Norwegian University of Science and Technology in the late 1980s.

Moving bed Bioreactor (MBBR) an economically solution for wastewater treatment if the "bulk" of the pollution load must be disposed of (as means of cost reduction) or if applicable discharge regulations aren't as strict.

With this application we provide advanced wastewater treatment solutions for the economic and municipal markets. These solutions significantly increase the capacity and efficiency of existing wastewater treatment plants, while minimizing the dimensions of latest plant deployments.

This method makes it possible to achieve good efficiency results of disposal with low energy consumption. This process is employed for the removal of organic substances, nitrification and denitrification.

The MBBR system consists of an activated sludge aeration system where the sludge is collected on recycled plastic carriers. These carriers have an indoor large surface for optimal contact water, air and bacteria.

The bacteria/activated sludge grow on the interior surface of the carriers. The bacteria break down the organic matter from the waste water. The aeration system keeps the carriers with activated sludge in motion. Only the additional amount of bacteria growth, the surplus sludge will come break away the carriers and can flow with the treated water towards the ultimate separator.

The system can contains a 1 stage or more stage system (see underneath schedule), counting on the precise demands. The specific bacteria remain in their own duty tank due to the very fact that the carriers remain in just 1 tank, protected by screens.

The MBBR process is often used for a spread of various applications to achieve the specified results, counting on the standard of the wastewater and therefore the discharge regulations.

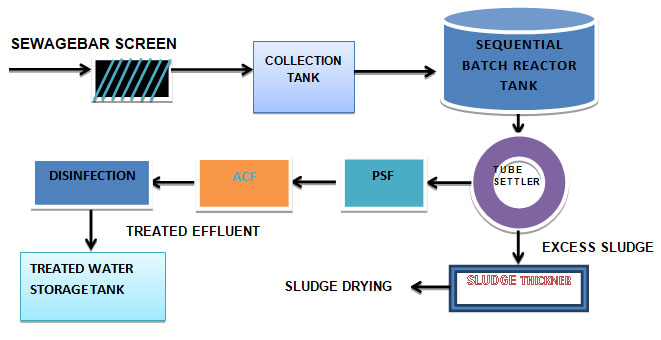

Design of MBBR based sewage treatment plant is not much complex to understand. For understanding of best and easy understanding of diagram for mbbr sewage treatment plant manufacturer please refer to the below mentioned design.

1- Capacity increase

2- Quality Improvement – BOD & Nitrogen Removal

3- Fast recovery from Process Upsets

4- Limited Footprint

5- Future Expansion

6- Minimize Process Complexity and Operator Attention

1- Economical very attractive

2- Compact (saves space)

3- Maintenance-friendly

4- Strong

5- High volume load

6- Simply to increase

7- Financial savings on discharge costs

MBBR STP Video

The author of the blog is associated with Netsol Water Solutions, which is into manufacturing Effluent Treatment Plant, Sewage Treatment Plant, and Water Treatment Plants.