- For Enquiry- 0120-2350053 || +91 9650608473 || +91 9650795306

- enquiry@netsolwater.com

This article aims to figure out the best technology for treating dairy effluent. It also discusses which chamber is essential in the treatment of dairy effluents.

The demand for milk and its associated products is increasing day by day. As a result, the dairy industry is keeping pace with its production faster to deliver better results to its consumers. They purchase the milk from farmers and then manufacture it in either bottle or make the milk products and then sell. During such processes, large quantities of effluents are generated, which are known as dairy effluents.

The Process after purchasing the milk from farmers and then manufacture the packaged milk or make the milk products generates wastewater is called Dairy Effluent. It further cateogerised in the major cateogeries as- Cooling Water, Sanitary Waste Water, Industrial Wastewater.

Dairy effluents contain high amounts of dissolved sugars, proteins, fats, and minerals etc. There are specific parameters of dairy effluents like Biological oxygen demand (BOD), Chemical oxygen demand (COD), Total suspended solids (TSS), and Total dissolved solids (TDS). It becomes indispensable to treat dairy effluents since they can cause much harm to the environment.

We use Effluent treatment plants to treat dairy wastewater. Generally, two types of methods are used in the treatment of dairy wastewater. The first one is Biological treatment, while the other is Chemical treatment. The most preferred one is biological treatment. Let us see how an ETP plant works in the treatment of dairy effluents.

The main aim of the Effluent treatment plant is to treat and utilise the waste products to avoid environmental degradation. Its objectives are to reduce the organic content, nutrients, and inactive potential pathogenic microorganisms or parasites in the wastewater. The procedure for the treatment of dairy effluent can be treated into four crucial steps:

a) Flow Equalisation: It is adopted to reduce the hydraulic loading in the waste stream. It comprises a holding tank and pumping device aimed at reducing the fluctuation of effluent discharge.

b) Screening: It is the most frequently used process. It uses screening devices such as vibrating screens, static screens, or rotary screens. The primary purpose of the screening devices is to hold the solids and remove them from the screen.

c) Skimming: It is a frequently adopted technique if large floatable solids are present in the solution. These solids are further collected and transferred into a disposed unit.

a) Sedimentation: This is the most common treatment employed to remove the solid particles present in the wastewater. A rectangular settling tank is used for this purpose. Its primary goal is to make the sludge settle at the bottom of the tank through sedimentation.

b) Floatation: In Floatation, the particles such as oil, grease, and suspended solids are removed from wastewater. The air bubbles created in the wastewater treatment helps in the removal process. The tiny particles get attached to the air bubbles, and the specific gravity of the particles become less, and hence the particles get separated.

Stabilisation ponds contain two ponds: Aerobic ponds that incorporate the use of mechanical aerators to supply atmospheric oxygen for enhancing biological oxidation and anaerobic ponds that involve the conversion of dissolved, suspended, and settled solids. Under this process, the anaerobes digest the organic matter.

In the activated sludge process, the portion is returned to the clarifier, i.e. settled sludge mixed with wastewater. This process consists of aerobic oxidation followed by sedimentation of activated sludge.

i) De-chlorination and disinfection.

ii) Reverse osmosis.

iii) Ion exchange.

Grit chamber is one of the most essential chambers for the dairy effluent treatment. These are the long narrow tanks designed to slow down the flow so that the solid particles settle out of the water. Grit helps in excessive wear and tear on the pumps and other plant equipment. Also, these help in the removal of inorganic materials so that they do not accumulate in the sludge digesters.

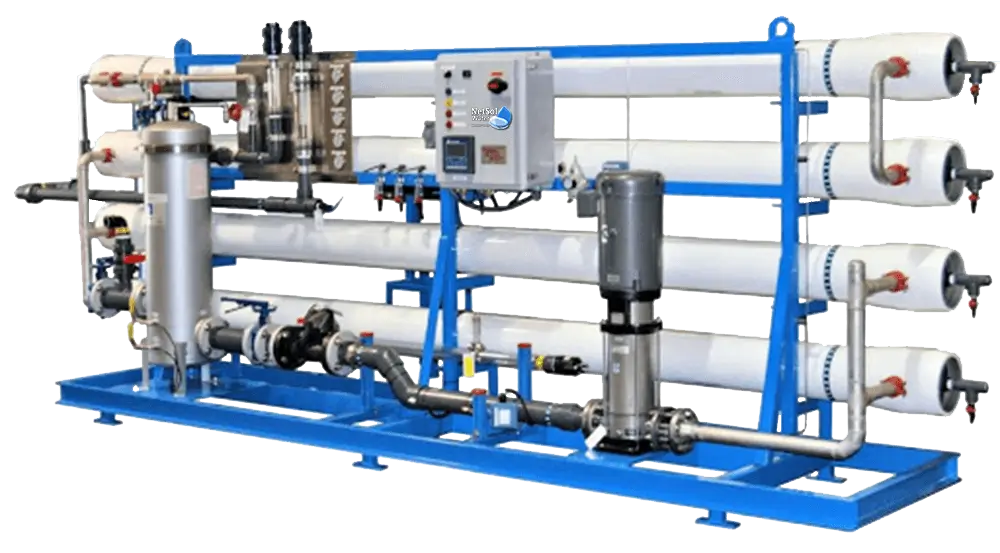

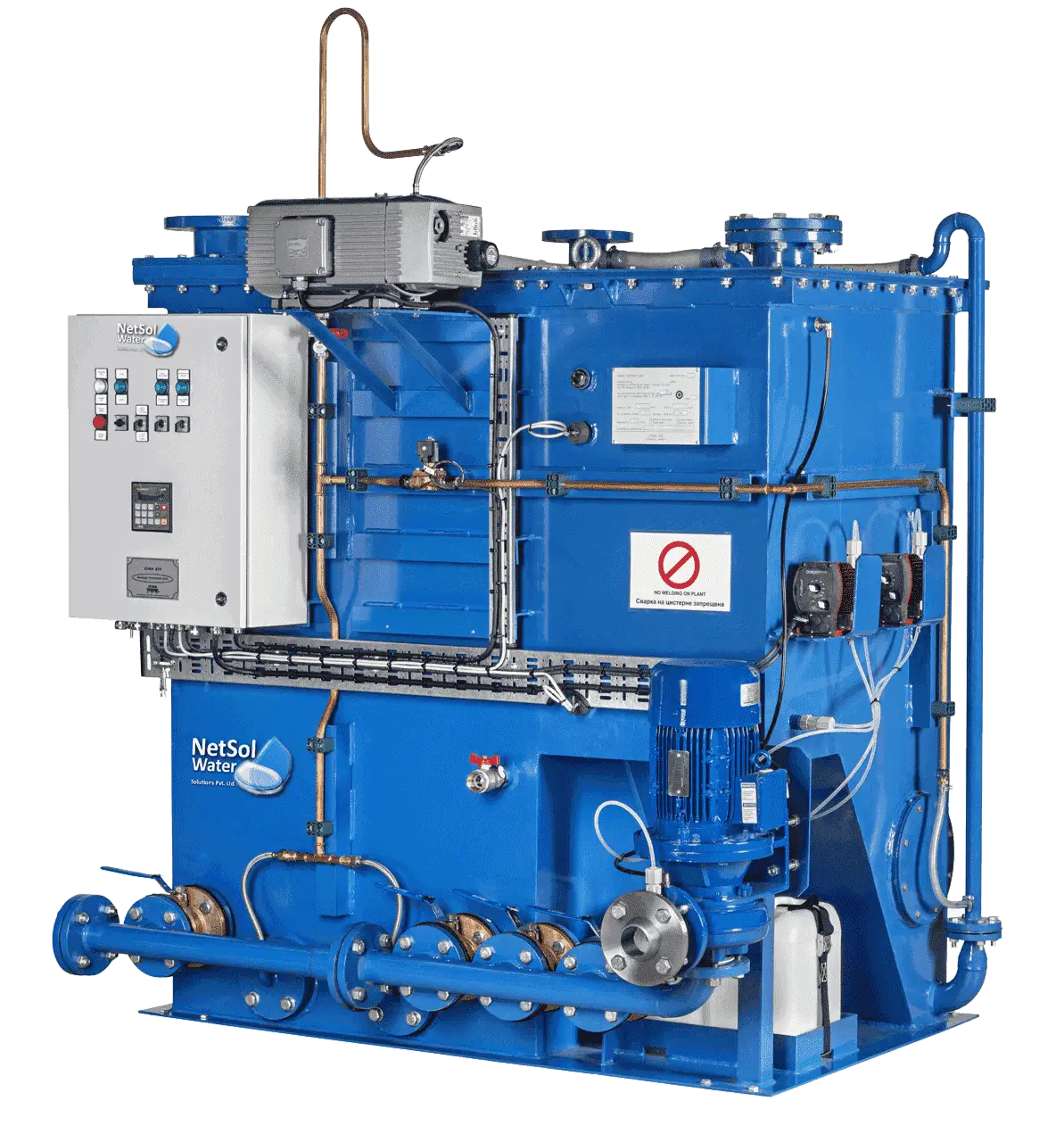

Netsol Water incorporates the latest technology that conforms to the predefined industrial standards and quality. Therefore you don’t have to worry about the quality and services. We are one of the most cost-effective companies in manufacturing sewage treatment plants and effluent treatment plants. It offers Effluent treatment plants for dairy ranging from small, medium, and large scale i.e. from 1000 Lph to 40,000 Lph.

If you have any doubts, please feel free to reach us. Contact us to discuss your requirements. We can be reached at 9650608473 and 9650795306, or feel free to leave your query at enquiry@netsolwater.com.