How are Bio aerosols being controlled?

Pathogens can get airborne as a result of wastewater aeration, but the correct aerator can reduce the risk.

Before effluent is released or reused, an effective disinfection stage destroys practically all bacteria and viruses that could be detrimental to the population, agriculture, and ecosystems. However, because disinfection is usually the last step in the treatment process, when wastewater is aerosolized at any earlier stage, plant personnel and the surrounding community are at greater risk of pathogen exposure. While aeration is one of the most common sources of bioaerosols in wastewater treatment, Netsol customises aerators and other aerosol-reducing devices.

Bio-aerosols are formed via splashing!

Many mechanical aerators used in activated sludge processes cause splashing, resulting in effluent aerosolization. Splashing, like bursting bubbles, contributes significantly to bio-aerosol generation. Aerators from Netsol mix and aerate without splashing, keeping the environment clean.

Subsurface aerators reduce odour near aeration tanks and regions adjacent to the wastewater treatment plants, potentially enhancing community relations and employee morale. They also reduce the risk of corrosion and structural damage to equipment that can be caused by constant splashing and misting.

Biological Hazards: Reducing the Risk

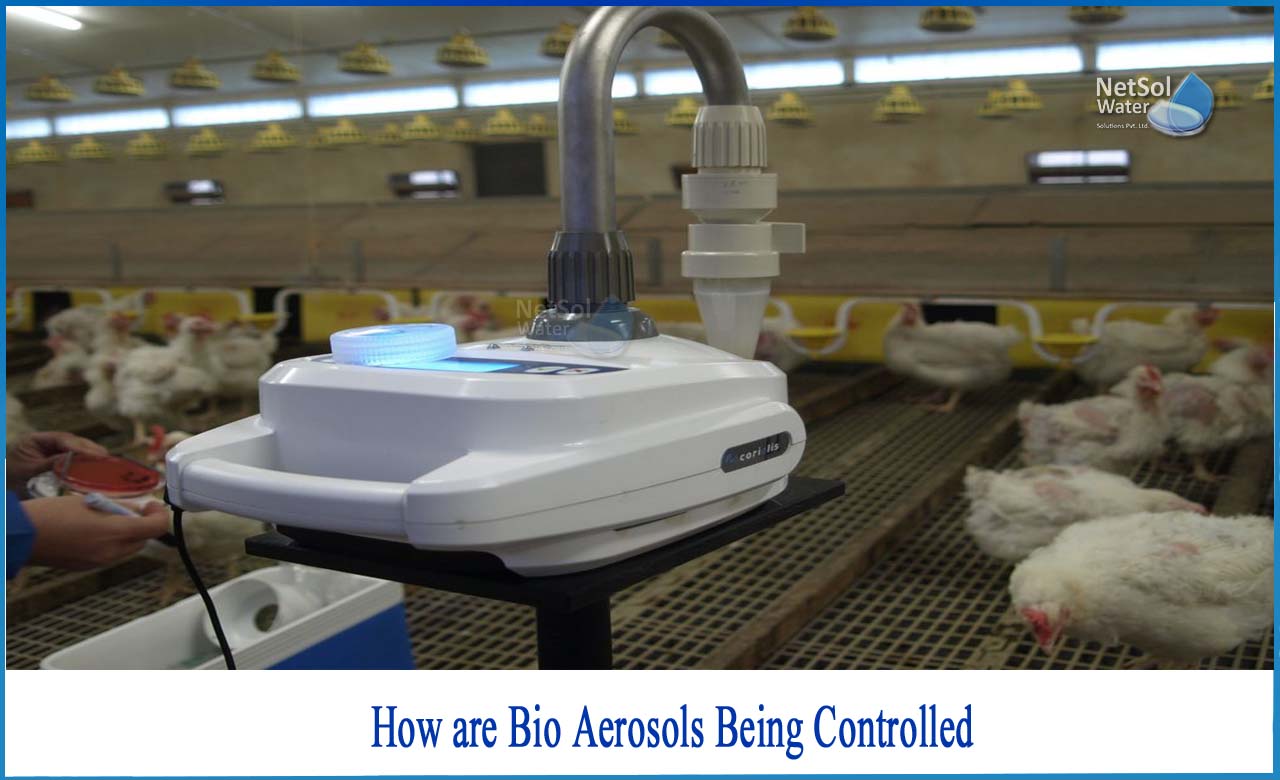

The quantity of airborne pathogens generated in wastewater treatment is largely determined by bubble size, according to a recent study by “Mengmeng Lou et al”. Researchers discovered that the bioaerosol levels generated by horizontal rotor and surface turbine aerators were substantially greater than those generated by air diffuser aerators among the three main aerator designs (air diffusion, horizontal rotor, and surface turbine).

Most pathogens were found to be aerosolized by surface turbine aeration, followed by horizontal rotor aeration. Air diffusion was discovered to be the least aerosolizing technique of aeration. Furthermore, the number of bacteria aerosolized by air diffusers was extremely close to the area's ambient values.

According to experts, air diffusion aerators can greatly reduce the danger of biological risks.The adoption of air diffusers as an aeration device for biological treatment would considerably reduce the risk of biological exposure to wastewater treatment plant workers.

MABR for No-Bubble Aeration

Membrane aerated biofilm reactor (MABR) technology, which uses passive aeration to virtually eliminate bubbles, is a ground-breaking new form of aerobic wastewater treatment. This method removes a lot of nutrients while using very little energy.

Benefits of MABR technology

1: Installation procedural ease

Attached growth treatment systems frequently necessitate the emptying and cleaning of tanks prior to installation. With typically connected growth systems, aeration diffusers, mechanical mixers, sieves, and filters to maintain standard medium are frequently required. Tank emptying, diffusers, sieves, or further mixing are not required with Netsol MABR modules.

2: Controlling biofilm thickness

To achieve the greatest performance, the thickness of the biofilm on MABR membrane can be measured and optimised.Using a vigorous scour to vary the layers of biofilm on demand helps guarantee that Carbon, Ammonia, or TN goals are met.

What can Netsol Water provide?

Netsol creates the most cutting-edge attached-growth media in the market today. Biology establishes itself on the outer surface of precision constructed, gas permeable, micro-bore tubes, and acquires the oxygen it requires straight across the membrane wall; no additional diffusers or aerators are necessary. Gases entering and exiting each MABR module can be conveniently monitored in real-time for oxygen transfer and other purposes.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.