What does a waste water facility do?

Before discharging wastewater into a river, a wastewater treatment facility improves the quality of the wastewater by removing suspended organic and inorganic solids as well as other materials. The pace at which wastewater arrives at the treatment process can fluctuate substantially during the day, so it's a good idea to equalize the flow before feeding it to the various treatment phases.

What is flow equalization?

The process of controlling flow velocity and composition is known as flow equalization. It is important to dampen extreme variations in flow and water quality in many municipal and industrial treatment procedures. It is critical to provide regular flow and loading to a biological process in order to ensure effective therapy. By holding high flow variations, equalization basins are designed to deliver consistent influent flow to downstream processes.

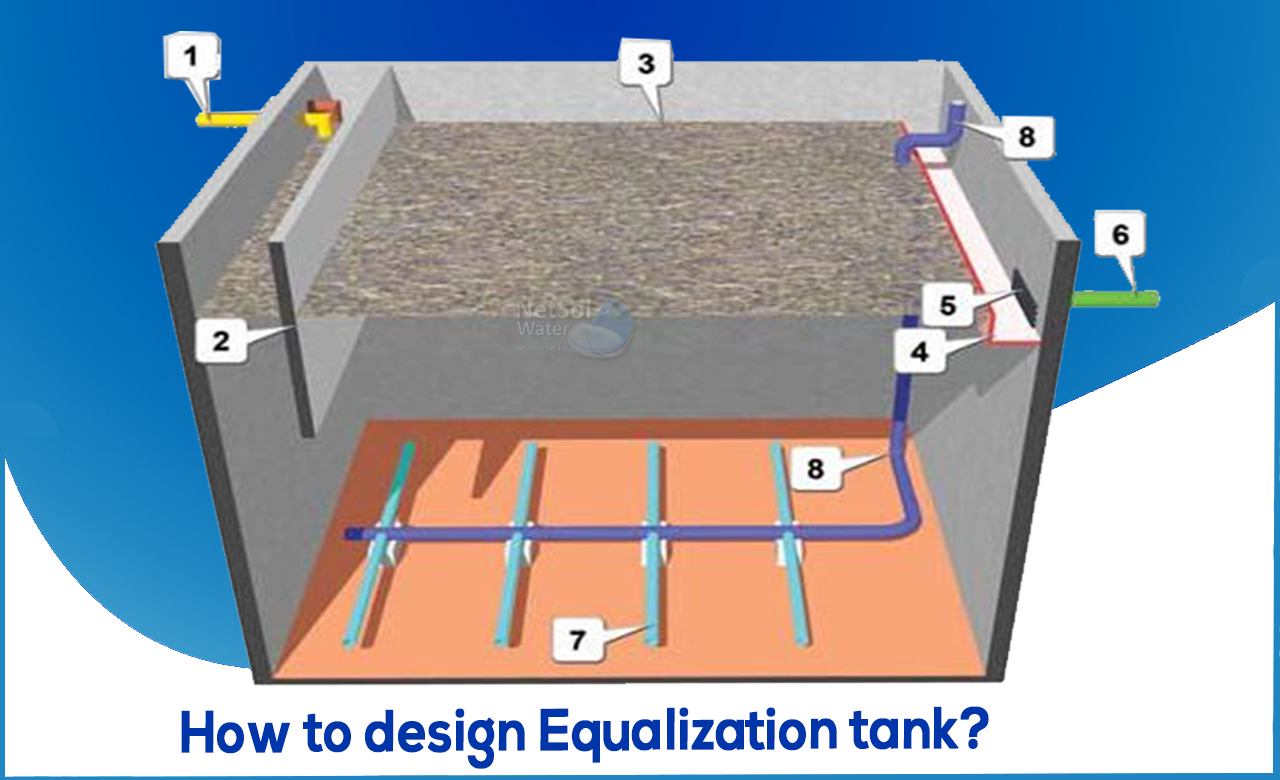

Design of an equalization tank

An input mass diagram, which plots cumulative inflow volume versus time of day, can be used to calculate the volume necessary for the equalization tank. Figure out the inflow mass diagrams to figure out how much equalization basin you'll need.

In practice, the tank's volume is kept 10 to 20% higher than the theoretical level. This extra volume will be used for the following:

> Not allowing full drawdown in order to operate continuous mixing or aeration (e.g. floating aerators)

> To get diluted wastewater, some volume must be provided to handle the concentrated stream.

> Protection against unanticipated flow changes.

Basin Geometry

If the basin is to be used for in-line equalization, the geometry should be such that it may be used as a continuous flow stirred tank reactor. This means that long rectangular basins should be avoided, and input and outlet sites should be chosen carefully to avoid short circuiting. The inlet should discharge near the mixing equipment in particular.

The following stages should be followed when designing a system:

Step 1: Calculate the frequency and length of the variance that needs to be deflected (this will allow design of the equalization basin).

Step 2: Determine the controlled release rate of the diverted flow that will allow normal operations to continue.

Step 3: Calculate the volume of the surge basin using the diverted volume so that continuous flow to the treatment facility may be maintained.

Step 4: Check that the equalized flow matches the discharge restrictions that were set.

The volume of the equalization basin – A step by step guide

1. The amount of in-line storage needed to equalize the flow rate is calculated.

2. The next step is to make a plot of the cumulative flow volume, as indicated in the diagram. The slope of the line drawn from the origin to the terminus of the inflow mass diagram shows the average flow rate for the day, as will be seen.

3. The final step is to figure out how much storage space you'll need. Drawing a line parallel to the average flow rate and tangent to the low point of the inflow mass curve graphic yields the needed storage volume. The vertical distance between the point of tangency and the straight line indicating the average flow rate represents the needed volume. As a result, the needed volume is the same as the volume of the equalization basin.

The author of the blog is associated with Netsol Water, which is into Effluent Treatment Plant manufacturing, Sewage Treatment Plant manufacturing, and Water Treatment Plants. For more information, consult- 9650608473 Netsol water Solutions!